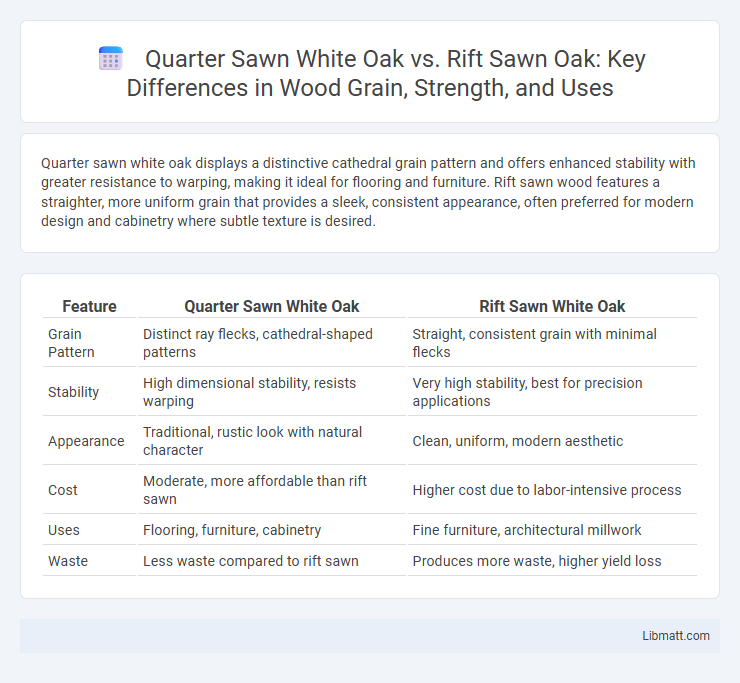

Quarter sawn white oak displays a distinctive cathedral grain pattern and offers enhanced stability with greater resistance to warping, making it ideal for flooring and furniture. Rift sawn wood features a straighter, more uniform grain that provides a sleek, consistent appearance, often preferred for modern design and cabinetry where subtle texture is desired.

Table of Comparison

| Feature | Quarter Sawn White Oak | Rift Sawn White Oak |

|---|---|---|

| Grain Pattern | Distinct ray flecks, cathedral-shaped patterns | Straight, consistent grain with minimal flecks |

| Stability | High dimensional stability, resists warping | Very high stability, best for precision applications |

| Appearance | Traditional, rustic look with natural character | Clean, uniform, modern aesthetic |

| Cost | Moderate, more affordable than rift sawn | Higher cost due to labor-intensive process |

| Uses | Flooring, furniture, cabinetry | Fine furniture, architectural millwork |

| Waste | Less waste compared to rift sawn | Produces more waste, higher yield loss |

Overview: Quarter Sawn vs. Rift Sawn White Oak

Quarter sawn white oak features growth rings cut at a 60 to 90-degree angle, producing straight grain patterns with prominent ray flecks, known for enhanced stability and resistance to warping. Rift sawn white oak is cut at a 30 to 60-degree angle, creating a more uniform, linear grain without the ray flecks, offering a sleek and consistent appearance with exceptional dimensional stability. Choosing between quarter sawn and rift sawn white oak depends on your preference for distinctive grain aesthetics and structural stability in your woodworking project.

Understanding Wood Grain Orientation

Quarter sawn white oak features a vertical grain orientation that enhances stability and highlights its distinctive ray flecks, while rift sawn wood displays a more uniform, straight grain with minimal medullary rays, offering a sleek appearance. This difference in grain orientation affects not only the aesthetic appeal but also the durability and resistance to warping of your wood projects. Choosing between quarter sawn and rift sawn white oak depends on your preference for visible grain patterns versus consistent texture.

Appearance and Grain Patterns

Quarter sawn white oak features a distinctive ray fleck pattern with straight grain lines, offering a bold and dramatic appearance ideal for traditional woodworking. Rift sawn white oak, on the other hand, displays a more uniform, linear grain with fewer visible flecks, creating a sleek and consistent look preferred in modern designs. Your choice between these cuts depends on whether you desire the pronounced texture of quarter sawn or the clean elegance of rift sawn grain patterns.

Strength and Stability

Quarter sawn white oak offers exceptional strength and stability due to its straight grain pattern, which reduces warping and cupping over time, making it ideal for flooring and furniture. Rift sawn white oak, with its more uniform vertical grain, provides slightly enhanced dimensional stability and fewer visible grain patterns, resulting in a smoother, more consistent surface. Choosing between the two depends on your preference for appearance and the structural demands of your project.

Cost Comparison

Quarter sawn white oak generally costs less than rift sawn due to the more efficient use of the log and higher yield during milling. Rift sawn white oak involves a more complex cutting process to achieve straighter grain patterns, which increases labor and waste, driving up the price. Your choice between the two will impact budget considerations, with quarter sawn offering a more cost-effective option without sacrificing durability or aesthetic appeal.

Common Uses in Furniture and Flooring

Quarter sawn white oak is commonly used in traditional furniture and hardwood flooring due to its prominent ray fleck pattern and enhanced stability, making it ideal for cabinets, tables, and flooring that require durability and a classic aesthetic. Rift sawn white oak, characterized by straight, narrow grain lines, is favored for modern furniture and flooring designs where a uniform, linear look is preferred, offering a sleek and minimalist appeal. Choosing between them depends on your preference for visual texture and the specific application in furniture or flooring projects.

Workability and Machining Differences

Quarter sawn white oak displays superior stability with tighter grain patterns, making it easier to machine without tear-out or splintering, ideal for intricate woodworking projects. Rift sawn white oak features a more consistent grain angle, resulting in smoother cuts and enhanced workability for precision milling and cabinetry. Understanding these machining differences helps you choose the best white oak cut for your specific craftsmanship needs.

Availability and Sourcing

Quarter sawn white oak is more widely available due to its traditional milling process, making it a popular choice for flooring and cabinetry with consistent grain patterns. Rift sawn white oak is less common and often sourced from specialty mills, as the cutting process yields narrower boards with a unique straight grain that reduces waste but limits availability. Both types require careful sourcing to ensure quality, with quarter sawn being more accessible in standard lumberyards and rift sawn typically found through niche suppliers.

Environmental Impact

Quarter sawn white oak generates less waste than rift sawn due to more efficient log utilization, reducing its environmental footprint. Rift sawn cuts tend to produce more offcuts, leading to higher resource consumption and waste. Choosing quarter sawn white oak supports sustainable forestry by maximizing material use while providing durable wood for your projects.

Choosing the Right Cut for Your Project

Quarter sawn white oak offers enhanced stability, pronounced grain patterns, and superior resistance to wear, making it ideal for flooring and furniture requiring durability and aesthetic appeal. Rift sawn white oak features a more uniform, linear grain, providing a sleek, modern look preferred in high-end cabinetry and architectural millwork. Selecting between quarter sawn and rift sawn white oak depends on your project's structural requirements and desired visual impact, with quarter sawn emphasizing texture and rift sawn emphasizing clean lines.

Quarter sawn white oak vs rift sawn Infographic

libmatt.com

libmatt.com