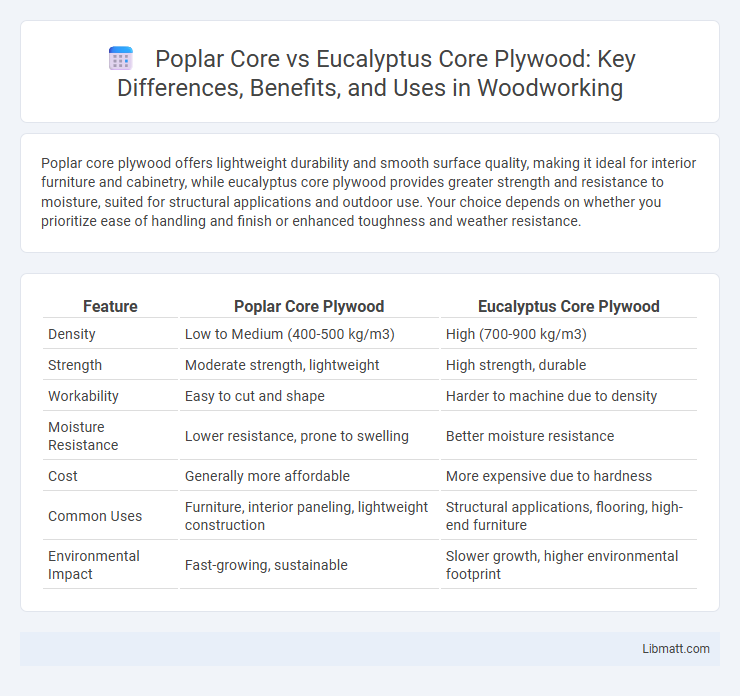

Poplar core plywood offers lightweight durability and smooth surface quality, making it ideal for interior furniture and cabinetry, while eucalyptus core plywood provides greater strength and resistance to moisture, suited for structural applications and outdoor use. Your choice depends on whether you prioritize ease of handling and finish or enhanced toughness and weather resistance.

Table of Comparison

| Feature | Poplar Core Plywood | Eucalyptus Core Plywood |

|---|---|---|

| Density | Low to Medium (400-500 kg/m3) | High (700-900 kg/m3) |

| Strength | Moderate strength, lightweight | High strength, durable |

| Workability | Easy to cut and shape | Harder to machine due to density |

| Moisture Resistance | Lower resistance, prone to swelling | Better moisture resistance |

| Cost | Generally more affordable | More expensive due to hardness |

| Common Uses | Furniture, interior paneling, lightweight construction | Structural applications, flooring, high-end furniture |

| Environmental Impact | Fast-growing, sustainable | Slower growth, higher environmental footprint |

Introduction to Plywood Core Materials

Poplar core plywood features lightweight, fine-grained hardwood known for its stability and smooth surface, making it ideal for furniture and cabinetry. Eucalyptus core plywood offers a denser, stronger hardwood core with superior durability and resistance to warping, favored in structural applications and heavy-duty uses. Both core materials influence plywood's strength, workability, and finishing quality, catering to different performance and cost requirements in construction and manufacturing.

Overview of Poplar Core Plywood

Poplar core plywood is known for its lightweight structure and consistent grain, making it ideal for furniture and cabinetry where weight reduction is crucial. The wood offers excellent stability and smooth surface finish, which enhances paint adhesion and overall aesthetics. Your choice of poplar core plywood ensures a balance of strength and ease of workability, suitable for both residential and commercial applications.

Overview of Eucalyptus Core Plywood

Eucalyptus core plywood is highly valued for its superior strength-to-weight ratio, making it ideal for structural applications such as flooring, cabinetry, and furniture manufacturing. The dense eucalyptus core provides enhanced durability and resistance to impact, while maintaining good dimensional stability under varying humidity conditions. This plywood type offers excellent screw-holding capacity and smooth surface finishes, which contribute to its popularity in both construction and decorative uses.

Strength and Durability Comparison

Poplar core plywood offers moderate strength and durability, making it suitable for lightweight furniture and interior applications, while eucalyptus core plywood is known for its higher density and superior strength, providing enhanced load-bearing capacity and resistance to wear. The natural hardness of eucalyptus improves the plywood's impact resistance and longevity under heavy use, whereas poplar core may be more prone to dents and damage over time. Choosing eucalyptus core plywood ensures your projects benefit from greater durability, especially in demanding environments requiring robust structural support.

Weight and Density Differences

Poplar core plywood typically has a lower density and lighter weight compared to eucalyptus core plywood, making it easier to handle and ideal for projects requiring less structural load. Eucalyptus core plywood offers higher density and increased strength, providing better durability and resistance to impact or heavy use. Choosing between these materials depends on whether your project prioritizes lightweight convenience or enhanced structural performance.

Workability and Machinability

Poplar core plywood offers excellent workability due to its softer texture, allowing easier cutting, shaping, and nailing with less risk of splintering, which benefits projects requiring precision and smooth finishing. Eucalyptus core plywood, while denser and harder, provides superior machinability for heavy-duty applications, holding screws and nails firmly and yielding durable edges that resist chipping during complex machining. Selecting between these cores depends on your project's needs for smooth handling (poplar) or robust machining performance (eucalyptus).

Cost and Economic Considerations

Poplar core plywood typically offers a lower cost advantage compared to eucalyptus core plywood due to the faster growth and wider availability of poplar trees. Eucalyptus core plywood, while often more expensive, provides enhanced strength and durability, making it a cost-effective choice for high-stress applications despite the higher initial investment. Evaluating project requirements and budget constraints is crucial when choosing between these two plywood core types to optimize economic value.

Environmental Sustainability Factors

Poplar core plywood generally exhibits higher environmental sustainability due to faster growth rates and more efficient carbon sequestration compared to eucalyptus core plywood, which often requires intensive water and pesticide use. Poplar trees are typically harvested from well-managed plantations that emphasize renewal and biodiversity, reducing the ecological impact relative to eucalyptus species that may contribute to soil degradation. The lower energy consumption and reduced chemical treatments involved in processing poplar core plywood further enhance its eco-friendly profile in construction and furniture applications.

Common Applications and Use Cases

Poplar core plywood is widely utilized in furniture making, cabinetry, and interior paneling due to its lightweight nature and smooth surface, which facilitates easy finishing. Eucalyptus core plywood is favored in structural applications and outdoor uses like flooring and decking, attributed to its superior strength and natural resistance to moisture and decay. Both types serve distinct roles where poplar core excels in aesthetic and indoor utility, while eucalyptus core offers durability and weather resistance for more demanding environments.

Which Core is Best for Your Project?

Poplar core plywood offers superior stability, smoothness, and is easier to machine, making it ideal for cabinetry and furniture where fine finishes are essential. Eucalyptus core plywood provides higher strength and moisture resistance, suitable for structural applications and outdoor projects requiring durability. Choose poplar core for precision and aesthetics, while eucalyptus core is better for heavy-duty, moisture-prone environments.

Poplar core vs eucalyptus core plywood Infographic

libmatt.com

libmatt.com