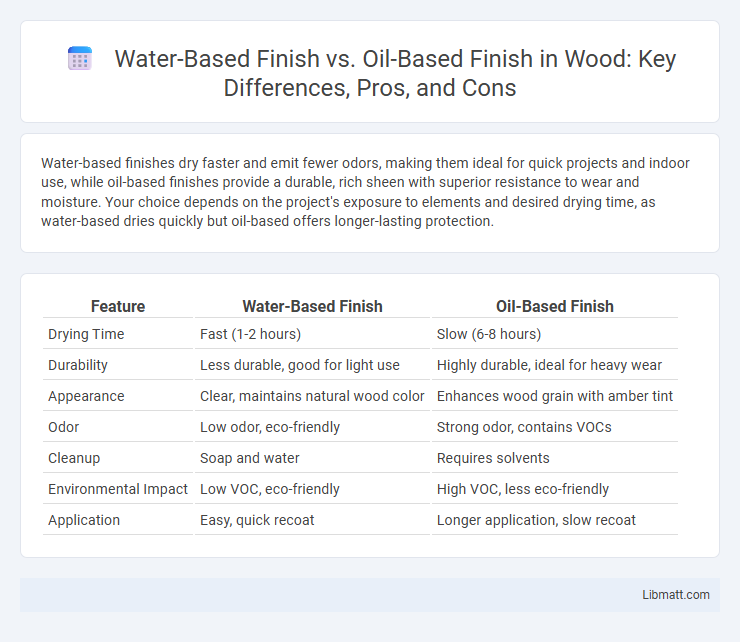

Water-based finishes dry faster and emit fewer odors, making them ideal for quick projects and indoor use, while oil-based finishes provide a durable, rich sheen with superior resistance to wear and moisture. Your choice depends on the project's exposure to elements and desired drying time, as water-based dries quickly but oil-based offers longer-lasting protection.

Table of Comparison

| Feature | Water-Based Finish | Oil-Based Finish |

|---|---|---|

| Drying Time | Fast (1-2 hours) | Slow (6-8 hours) |

| Durability | Less durable, good for light use | Highly durable, ideal for heavy wear |

| Appearance | Clear, maintains natural wood color | Enhances wood grain with amber tint |

| Odor | Low odor, eco-friendly | Strong odor, contains VOCs |

| Cleanup | Soap and water | Requires solvents |

| Environmental Impact | Low VOC, eco-friendly | High VOC, less eco-friendly |

| Application | Easy, quick recoat | Longer application, slow recoat |

Introduction to Water-Based and Oil-Based Finishes

Water-based finishes offer faster drying times, lower odor, and easier cleanup compared to oil-based finishes, making them ideal for indoor projects and eco-conscious users. Oil-based finishes provide a durable, glossy coating with superior resistance to wear and chemicals, preferred for high-traffic areas and exterior applications. Choosing between these finishes depends on the desired appearance, drying time, and environmental impact for your woodworking or furniture project.

Key Differences Between Water-Based and Oil-Based Finishes

Water-based finishes dry faster and emit fewer volatile organic compounds (VOCs), making them more environmentally friendly and suitable for indoor use. Oil-based finishes provide a deeper, richer color and superior durability, especially for high-traffic surfaces or outdoor furniture. Your choice depends on desired appearance, drying time, and environmental considerations.

Application Process: Water-Based vs Oil-Based Finish

Water-based finishes dry faster and emit fewer volatile organic compounds (VOCs), making the application process cleaner and more convenient for indoor use. Oil-based finishes require longer drying times and multiple coats to achieve a durable, deep finish, often involving stronger solvents and more ventilation. Choosing between water-based and oil-based finishes depends on project timeline, desired durability, and environmental considerations.

Drying Time and Curing Characteristics

Water-based finishes typically dry within 1 to 2 hours due to rapid water evaporation, allowing for quicker recoating and use. Oil-based finishes require 6 to 8 hours or more to dry as solvents evaporate slower, but they cure over several days to weeks, forming a durable hard film. The curing process of oil-based finishes provides enhanced chemical resistance, whereas water-based finishes achieve full hardness faster but may remain softer initially.

Durability and Protection Comparison

Water-based finishes offer excellent durability with fast drying times and resistance to yellowing, making them ideal for maintaining the natural color of wood surfaces. Oil-based finishes provide superior protection against scratches and moisture due to their thicker consistency and longer curing process, creating a robust, long-lasting barrier. Your choice depends on the desired balance between quick application and maximum durability for the specific wood project.

Appearance: Clarity, Color, and Sheen

Water-based finishes provide a clear, natural appearance with minimal color alteration, enhancing the wood's original hue and offering a bright, satin sheen. Oil-based finishes tend to impart a warm amber tone, enriching the wood's color while creating a glossy, richer sheen. Your choice depends on whether you prefer a clean, true-to-wood look or a deeper, warmer finish with added depth.

Environmental Impact and VOC Emissions

Water-based finishes produce significantly lower volatile organic compounds (VOC) emissions compared to oil-based finishes, making them a more environmentally friendly choice. Oil-based finishes release higher levels of VOCs, contributing to indoor air pollution and smog formation, which negatively impacts air quality. Choosing water-based finishes can reduce your environmental footprint and improve indoor air health by minimizing harmful chemical emissions.

Maintenance and Touch-Up Requirements

Water-based finishes require less frequent maintenance due to their resistance to yellowing and quick drying times, making touch-ups easier and less noticeable. Oil-based finishes need more regular maintenance as they are prone to darkening and surface wear, which can make touch-ups more challenging to blend seamlessly. Choosing water-based finishes often results in lower long-term upkeep costs and simpler repair processes.

Cost Considerations and Value

Water-based finishes typically cost more upfront but offer lower long-term expenses due to faster drying times and reduced need for ventilation. Oil-based finishes are generally less expensive initially but may require additional maintenance and longer curing periods, increasing overall costs. Value-wise, water-based options provide better environmental benefits and durability, making them a cost-effective choice for high-traffic or moisture-prone areas.

Choosing the Right Finish for Your Project

Water-based finishes offer faster drying times, lower odor, and easier cleanup, making them ideal for indoor projects and surfaces that require frequent use. Oil-based finishes provide superior durability, deeper color enhancement, and better protection against wear, suitable for high-traffic areas or outdoor use. Your choice between water-based and oil-based finishes depends on factors like project location, desired durability, drying time, and environmental considerations.

Water-based finish vs Oil-based finish Infographic

libmatt.com

libmatt.com