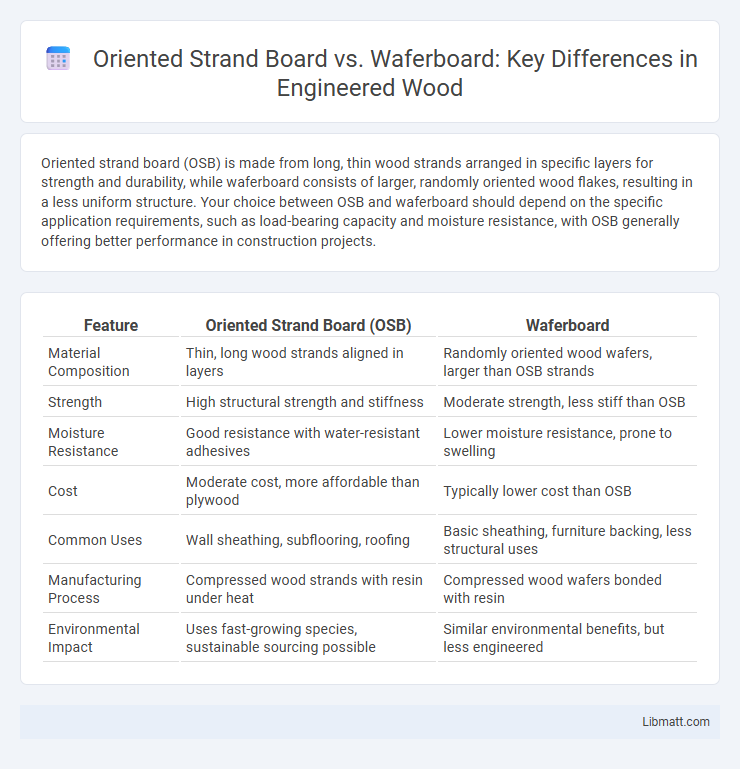

Oriented strand board (OSB) is made from long, thin wood strands arranged in specific layers for strength and durability, while waferboard consists of larger, randomly oriented wood flakes, resulting in a less uniform structure. Your choice between OSB and waferboard should depend on the specific application requirements, such as load-bearing capacity and moisture resistance, with OSB generally offering better performance in construction projects.

Table of Comparison

| Feature | Oriented Strand Board (OSB) | Waferboard |

|---|---|---|

| Material Composition | Thin, long wood strands aligned in layers | Randomly oriented wood wafers, larger than OSB strands |

| Strength | High structural strength and stiffness | Moderate strength, less stiff than OSB |

| Moisture Resistance | Good resistance with water-resistant adhesives | Lower moisture resistance, prone to swelling |

| Cost | Moderate cost, more affordable than plywood | Typically lower cost than OSB |

| Common Uses | Wall sheathing, subflooring, roofing | Basic sheathing, furniture backing, less structural uses |

| Manufacturing Process | Compressed wood strands with resin under heat | Compressed wood wafers bonded with resin |

| Environmental Impact | Uses fast-growing species, sustainable sourcing possible | Similar environmental benefits, but less engineered |

Introduction to Oriented Strand Board (OSB) and Waferboard

Oriented Strand Board (OSB) consists of compressed layers of wood strands arranged in specific orientations, offering strength and durability for construction applications. Waferboard is a similar engineered wood product made from randomly oriented wood flakes bonded with resins, providing a cost-effective alternative for sheathing and subflooring. Understanding the differences in manufacturing and structural properties helps you choose the right panel for your building needs.

Composition and Manufacturing Process

Oriented strand board (OSB) consists of layers of thin wood strands arranged in specific orientations, bonded together with resin under heat and pressure, enhancing its strength and durability. Waferboard is manufactured using larger, randomly oriented wood flakes mixed with adhesive and compressed, resulting in a less uniform structure compared to OSB. The distinct strand alignment in OSB provides superior load-bearing performance, whereas waferboard's composition makes it a cost-effective alternative for certain construction applications.

Structural Differences: OSB vs Waferboard

Oriented strand board (OSB) features long, thin wood strands aligned in specific directions and bonded with adhesives, providing superior strength and load-bearing capacity compared to waferboard. Waferboard consists of randomly arranged, flat wood flakes, resulting in a more uniform but weaker panel structure with less resistance to bending and shear forces. The structural orientation of OSB strands enhances dimensional stability and durability, making it the preferred choice for structural applications like flooring and roofing.

Mechanical Strength and Performance

Oriented strand board (OSB) demonstrates higher mechanical strength and better performance compared to waferboard due to the alignment of wood strands in specific orientations, which enhances load-bearing capacity and dimensional stability. Waferboard consists of randomly arranged wood flakes that result in lower shear strength and reduced resistance to warping under moisture exposure. OSB is widely preferred in structural applications such as flooring, roofing, and wall sheathing due to its superior stiffness and consistent strength properties.

Moisture Resistance and Durability

Oriented Strand Board (OSB) offers superior moisture resistance compared to Waferboard due to its engineered layered structure and waterproof adhesives, making it ideal for exterior applications where exposure to humidity and water is common. Waferboard, while structurally similar, has lower durability and tends to absorb moisture more readily, leading to swelling and reduced lifespan in damp environments. Selecting OSB for your projects ensures enhanced durability and moisture resistance, providing longer-lasting performance under challenging conditions.

Cost Comparison and Availability

Oriented Strand Board (OSB) generally costs more than Waferboard due to its superior strength and durability, making it a preferred choice for structural applications. Waferboard, while less expensive, offers more limited availability and lower performance, often restricting its use to non-structural projects. Your decision should balance budget constraints with the need for material strength, keeping in mind that OSB is widely available at most building supply stores.

Common Applications in Construction

Oriented strand board (OSB) is widely used for wall sheathing, roof decking, and subflooring due to its strength and moisture resistance, making it a preferred choice for structural applications in residential and commercial construction. Waferboard, often found in furniture manufacturing and non-load-bearing interior paneling, is less suitable for exterior or load-bearing purposes because of its lower strength and water resistance compared to OSB. Your construction project will benefit from OSB when durability and weather resistance are crucial factors.

Environmental Impact and Sustainability

Oriented strand board (OSB) is generally considered more environmentally sustainable than waferboard due to its production from fast-growing, small-diameter trees and the efficient use of wood strands, which reduces waste. OSB manufacturers often utilize formaldehyde-free adhesives and implement sustainable forestry practices, lowering its carbon footprint compared to waferboard, which uses larger wood flakes and can involve adhesives with higher volatile organic compound (VOC) emissions. Both materials contribute to resource-efficient construction, but OSB's superior mechanical properties and higher recyclability rates make it a preferred choice for eco-conscious building projects.

Pros and Cons of OSB

Oriented strand board (OSB) offers superior strength, stiffness, and moisture resistance compared to waferboard, making it ideal for structural applications such as flooring, roofing, and wall sheathing. OSB's manufacturing process aligns wood strands in specific orientations, providing enhanced load-bearing capacity, but it can be heavier and more expensive than waferboard, which uses randomly oriented wood flakes. Your choice depends on balancing OSB's durability and performance benefits against its cost and weight in your construction project.

Pros and Cons of Waferboard

Waferboard offers an affordable option for structural sheathing and furniture manufacturing due to its low cost and easy availability, but it often has lower strength and moisture resistance compared to oriented strand board (OSB). Its large, flat wood flakes give waferboard a smoother surface but contribute to inferior mechanical properties and reduced durability in wet conditions. Despite its economic advantages, waferboard is less suitable for load-bearing applications and outdoor exposure where OSB typically excels.

Oriented strand board vs Waferboard Infographic

libmatt.com

libmatt.com