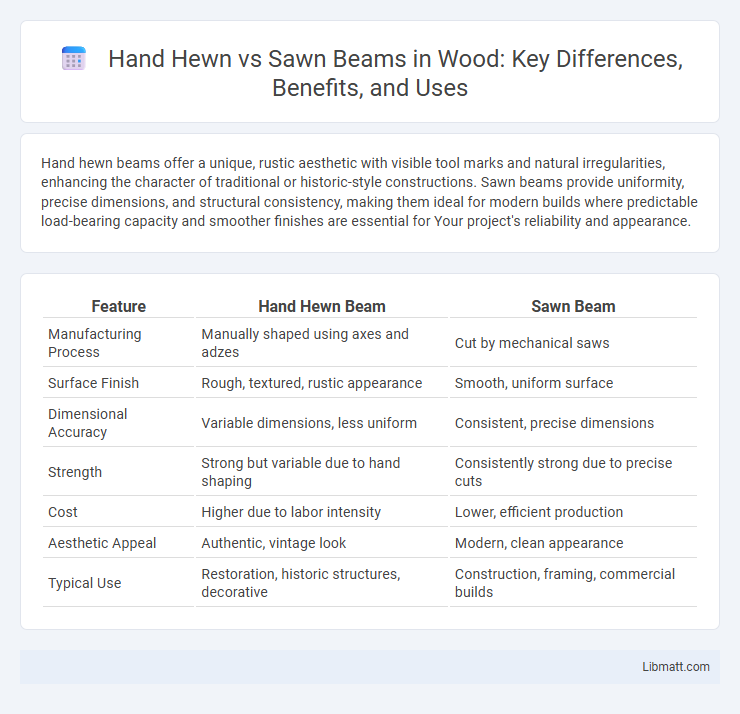

Hand hewn beams offer a unique, rustic aesthetic with visible tool marks and natural irregularities, enhancing the character of traditional or historic-style constructions. Sawn beams provide uniformity, precise dimensions, and structural consistency, making them ideal for modern builds where predictable load-bearing capacity and smoother finishes are essential for Your project's reliability and appearance.

Table of Comparison

| Feature | Hand Hewn Beam | Sawn Beam |

|---|---|---|

| Manufacturing Process | Manually shaped using axes and adzes | Cut by mechanical saws |

| Surface Finish | Rough, textured, rustic appearance | Smooth, uniform surface |

| Dimensional Accuracy | Variable dimensions, less uniform | Consistent, precise dimensions |

| Strength | Strong but variable due to hand shaping | Consistently strong due to precise cuts |

| Cost | Higher due to labor intensity | Lower, efficient production |

| Aesthetic Appeal | Authentic, vintage look | Modern, clean appearance |

| Typical Use | Restoration, historic structures, decorative | Construction, framing, commercial builds |

Introduction to Hand Hewn and Sawn Beams

Hand hewn beams are crafted by manually shaping logs with axes or adzes, resulting in a rustic texture and unique character. Sawn beams are produced using mechanical saws, offering uniform dimensions and a smoother finish ideal for modern construction. The choice between hand hewn and sawn beams impacts aesthetic appeal, structural integrity, and historical authenticity in woodworking and building projects.

Historical Background of Beam Crafting

Hand hewn beams, crafted using axes and adzes, date back thousands of years and represent traditional woodworking techniques utilized before the Industrial Revolution, reflecting the craftsmanship of early builders. Sawn beams emerged with the advent of sawmills in the 18th century, allowing for more uniform, faster production, and revolutionizing construction practices. Understanding the historical background of beam crafting highlights the transition from labor-intensive manual methods to mechanized processes, influencing the aesthetic and structural qualities of your timber construction.

Defining Hand Hewn Beams

Hand hewn beams are traditionally crafted by shaping logs using axes and adzes, producing uneven surfaces that reflect artisanal workmanship and historical building methods. These beams exhibit unique textures and irregularities, distinguishing them from uniformly smooth sawn beams produced by mechanical sawmills. Typically found in historic or rustic structures, hand hewn beams offer superior character and may display tool marks that enhance their aesthetic and structural authenticity.

Understanding Sawn Beams

Sawn beams are cut directly from logs using sawmills, offering consistent dimensions and smooth surfaces ideal for modern construction. These beams provide uniform strength and are easier to work with due to their precise sizing, making them more predictable in structural applications. Understanding sawn beams helps you choose materials that balance durability and efficiency for your building projects.

Visual Differences: Texture and Appearance

Hand hewn beams showcase a rugged, textured surface with visible axe marks and irregularities, reflecting traditional craftsmanship and a rustic charm. In contrast, sawn beams present a smooth, uniform appearance with straight edges and consistent thickness, typically produced by modern sawmills. Your choice between hand hewn and sawn beams will significantly impact the aesthetic, with hand hewn beams offering authenticity and character, while sawn beams provide a clean, polished look.

Structural Strength and Durability Comparison

Hand hewn beams typically exhibit greater durability due to their dense wood fibers and natural grain alignment, which enhances load-bearing capacity and resistance to splitting. Sawn beams offer more uniform dimensions and surface smoothness but may have reduced strength compared to hand hewn beams because of the mechanical cutting process disrupting wood fibers. When considering structural strength, hand hewn beams often outperform sawn beams, making them preferable in applications demanding exceptional durability and load resistance.

Cost Analysis: Hand Hewn vs Sawn Beams

Hand hewn beams typically cost more due to labor-intensive craftsmanship and limited availability of skilled artisans, often ranging from $40 to $60 per linear foot. Sawn beams, produced using modern milling methods, generally cost between $15 and $35 per linear foot, making them a more budget-friendly option for construction projects. The choice between hand hewn and sawn beams impacts overall project costs significantly, especially when considering installation complexity and the desired aesthetic value.

Environmental Impact and Sustainability

Hand hewn beams typically have a lower environmental impact because they use traditional methods that minimize waste and avoid energy-intensive machinery, promoting sustainability. Sawn beams, produced by modern sawmills, often result in higher energy consumption and increased carbon emissions due to mechanical processing but can optimize wood usage with precise cuts. Choosing hand hewn beams for your project supports eco-friendly practices by utilizing local timber and preserving natural textures, aligning with sustainable construction principles.

Best Uses and Applications of Each Beam Type

Hand hewn beams offer a rustic, sturdy look ideal for restoration projects, historic homes, and timber frame construction where authenticity is key. Sawn beams provide precise dimensions and uniformity, making them suitable for modern construction, commercial buildings, and structural applications requiring consistency and strength. Choosing between hand hewn and sawn beams depends on your project's aesthetic goals and structural needs, with hand hewn beams enhancing character and sawn beams ensuring reliability.

Choosing the Right Beam for Your Project

Choosing the right beam for your project depends on factors such as aesthetic preference, structural requirements, and budget. Hand hewn beams offer a rustic, authentic appearance with unique textures, ideal for traditional or historic designs, while sawn beams provide uniformity, precise dimensions, and often greater availability suited for modern construction. Your decision should balance the visual impact and performance to ensure the beam meets both design goals and load-bearing needs.

Hand hewn vs Sawn beam Infographic

libmatt.com

libmatt.com