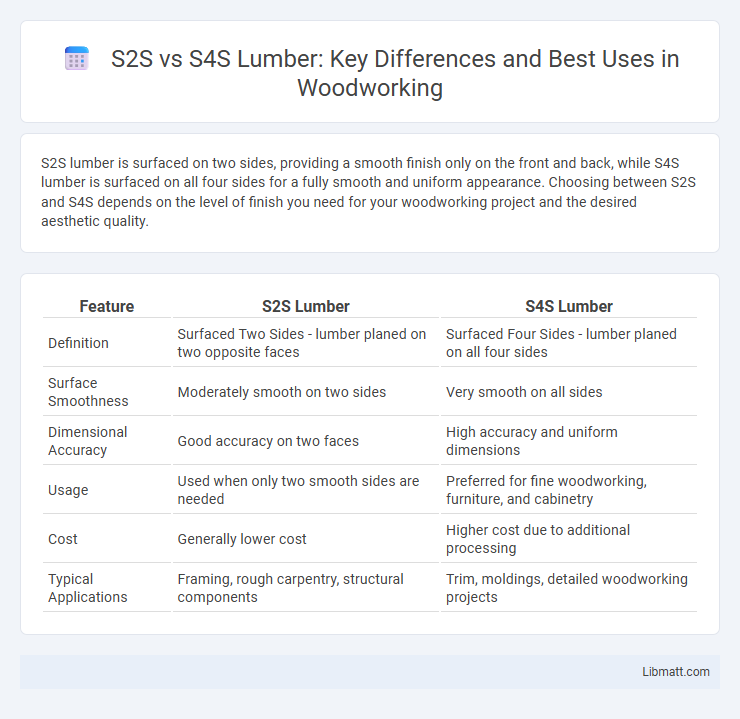

S2S lumber is surfaced on two sides, providing a smooth finish only on the front and back, while S4S lumber is surfaced on all four sides for a fully smooth and uniform appearance. Choosing between S2S and S4S depends on the level of finish you need for your woodworking project and the desired aesthetic quality.

Table of Comparison

| Feature | S2S Lumber | S4S Lumber |

|---|---|---|

| Definition | Surfaced Two Sides - lumber planed on two opposite faces | Surfaced Four Sides - lumber planed on all four sides |

| Surface Smoothness | Moderately smooth on two sides | Very smooth on all sides |

| Dimensional Accuracy | Good accuracy on two faces | High accuracy and uniform dimensions |

| Usage | Used when only two smooth sides are needed | Preferred for fine woodworking, furniture, and cabinetry |

| Cost | Generally lower cost | Higher cost due to additional processing |

| Typical Applications | Framing, rough carpentry, structural components | Trim, moldings, detailed woodworking projects |

Introduction to S2S and S4S Lumber

S2S (Surfaced Two Sides) and S4S (Surfaced Four Sides) lumber refer to wood that has been planed smooth on two or four sides, respectively, enhancing precision and ease of use in woodworking projects. S2S lumber has two rough or unplaned sides, while S4S lumber is fully planed on all sides, providing uniform thickness and smooth surfaces ideal for visible finishes. Choosing between S2S and S4S affects your project's finish quality and assembly accuracy, depending on whether you need ready-to-use wood or plan to customize the texture and dimensions further.

Understanding Lumber Surfacing Terms

S2S (Surfaced Two Sides) lumber has two of its four surfaces planed smooth, typically the wide faces, providing a uniform finish ideal for visible applications. S4S (Surfaced Four Sides) lumber undergoes milling on all four sides, ensuring consistent dimensions and a ready-to-use smooth surface perfect for precise woodworking and high-quality finishes. Understanding these surfacing terms helps you select the right lumber that meets your project's aesthetic and functional requirements efficiently.

What is S2S Lumber?

S2S lumber, or surfaced two sides lumber, refers to wood that has been planed on two opposite faces to create a smooth, even surface, improving its dimensional accuracy and appearance. It is commonly used in woodworking projects where a clean, finished look is desired without the additional cost of fully planing all four sides. This type of lumber allows for easier handling and assembly while providing a stable base for further machining or finishing.

What is S4S Lumber?

S4S lumber, or Surfaced Four Sides lumber, is wood that has been planed on all four sides, resulting in smooth, uniform dimensions ideal for precise woodworking projects. This milling process removes rough outer layers, providing a consistent surface that simplifies finishing and jointing tasks. Your choice of S4S lumber ensures accuracy and a cleaner appearance compared to rough-sawn or S2S lumber.

Key Differences Between S2S and S4S

S2S (Surfaced Two Sides) lumber is planed on two opposite faces, providing a smoother surface suitable for projects requiring flat sides but rough edges. S4S (Surfaced Four Sides) lumber is planed on all four sides, offering a fully smooth finish ideal for precise woodworking and visible applications. Choosing between S2S and S4S depends on Your project's need for finish quality and dimensional accuracy.

Pros and Cons of S2S Lumber

S2S lumber, or surfaced two sides lumber, offers smooth, uniform surfaces on two faces, making it ideal for fine woodworking and visible applications, which reduces sanding time and improves finish quality. However, S2S lumber tends to retain its rough edges on the unsurfaced sides, potentially requiring additional processing for projects demanding fully smooth boards, and it may cost more than rough-sawn lumber due to milling. Its consistent thickness and width are advantageous for precise joinery but limit flexibility in size adjustment compared to rough lumber options.

Pros and Cons of S4S Lumber

S4S lumber, or surfaced four sides, offers smooth, uniform surfaces ideal for fine woodworking and finished projects, reducing the need for sanding and enhancing aesthetic appeal. However, it typically costs more than S2S lumber due to the extra processing and may not be necessary for rough framing or structural uses where appearance is less critical. Your choice depends on whether you prioritize finish quality or budget efficiency in your lumber selection.

Common Applications for S2S vs S4S

S2S lumber, with its two surfaced sides, is commonly used for framing, shelving, and general construction where precise thickness is less critical. S4S lumber, featuring four surfaced sides, is preferred for cabinetry, furniture making, and trim work requiring smooth, finished edges and consistent dimensions. Builders select S2S for cost-effective projects and S4S when appearance and exact sizing are essential.

How to Choose Between S2S and S4S

Choosing between S2S (surfaced on two sides) and S4S (surfaced on four sides) lumber depends on your project's precision and finish requirements. S4S lumber offers a smoother, more uniform finish on all sides, ideal for visible or fine woodworking tasks, while S2S provides a finished look on only two faces, making it more cost-effective for structural or hidden applications. Assess your need for dimensional accuracy and surface quality to ensure Your project benefits from the appropriate lumber type without unnecessary expense.

S2S vs S4S Lumber: Cost and Availability

S2S lumber, surfaced on two sides, typically costs less and is more readily available than S4S lumber, which is surfaced on all four sides for a smoother finish. Your choice affects budget and delivery time, as S4S may require longer lead times due to additional processing. Considering project needs, S2S offers a cost-effective option with wide availability, while S4S provides superior quality at a higher price point.

S2S vs S4S lumber Infographic

libmatt.com

libmatt.com