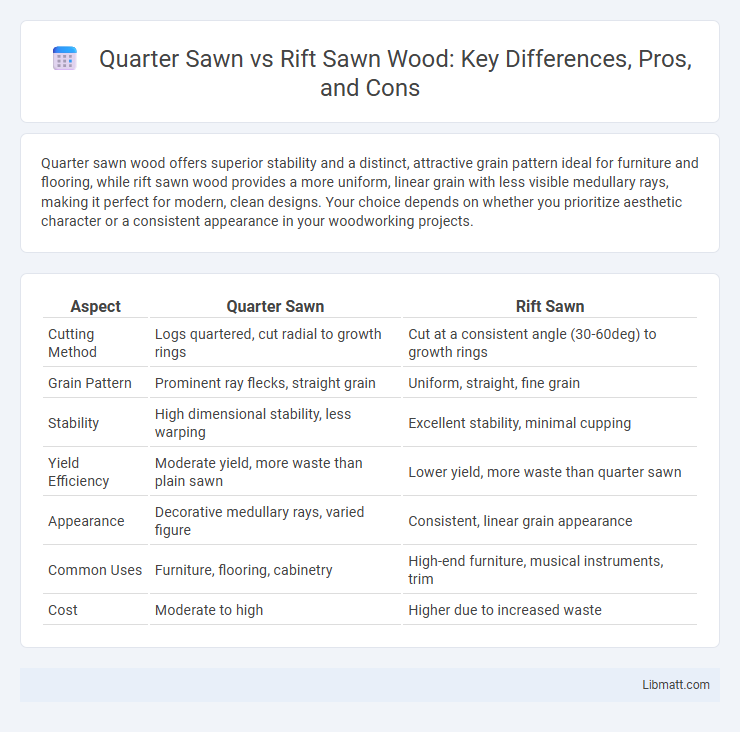

Quarter sawn wood offers superior stability and a distinct, attractive grain pattern ideal for furniture and flooring, while rift sawn wood provides a more uniform, linear grain with less visible medullary rays, making it perfect for modern, clean designs. Your choice depends on whether you prioritize aesthetic character or a consistent appearance in your woodworking projects.

Table of Comparison

| Aspect | Quarter Sawn | Rift Sawn |

|---|---|---|

| Cutting Method | Logs quartered, cut radial to growth rings | Cut at a consistent angle (30-60deg) to growth rings |

| Grain Pattern | Prominent ray flecks, straight grain | Uniform, straight, fine grain |

| Stability | High dimensional stability, less warping | Excellent stability, minimal cupping |

| Yield Efficiency | Moderate yield, more waste than plain sawn | Lower yield, more waste than quarter sawn |

| Appearance | Decorative medullary rays, varied figure | Consistent, linear grain appearance |

| Common Uses | Furniture, flooring, cabinetry | High-end furniture, musical instruments, trim |

| Cost | Moderate to high | Higher due to increased waste |

Introduction to Wood Sawn Methods

Quarter sawn wood is produced by cutting logs into quarters before sawing, resulting in boards with a straight grain pattern and enhanced dimensional stability. Rift sawn wood is cut at a slightly different angle, producing a consistent grain with minimal medullary rays, often preferred for its uniform appearance in fine woodworking. Your choice between quarter sawn and rift sawn depends on the desired aesthetic and structural properties for your woodworking project.

What is Quarter Sawn Lumber?

Quarter sawn lumber is produced by cutting logs into quarters before sawing perpendicular to the growth rings, resulting in boards with a straight grain pattern and enhanced stability. This method reduces warping and cupping, making quarter sawn wood ideal for flooring, furniture, and cabinetry where durability and aesthetics are crucial. Your choice of quarter sawn lumber ensures superior strength and a unique, attractive grain compared to other sawing techniques.

What is Rift Sawn Lumber?

Rift sawn lumber is produced by cutting logs at a precise angle between 30 and 60 degrees to the growth rings, resulting in a straight grain pattern that is both visually appealing and structurally stable. This method reduces wood warping and enhances durability, making it ideal for high-quality furniture and flooring. Understanding the characteristics of rift sawn lumber can help you select the best wood for projects requiring consistent appearance and strength.

Differences Between Quarter Sawn and Rift Sawn

Quarter sawn wood features growth rings angled between 60 to 90 degrees to the board's surface, resulting in a distinctive grain pattern with medullary rays that enhance stability and aesthetic appeal. Rift sawn wood is cut at a consistent 30 to 60-degree angle to the growth rings, producing a straighter grain with fewer flecks and a uniform texture ideal for modern, clean designs. The key differences lie in grain appearance, stability, and waste efficiency, with quarter sawn offering more decorative patterns and rift sawn providing a sleek, linear look.

Grain Patterns: Quarter Sawn vs Rift Sawn

Quarter sawn wood exhibits a distinctive ray fleck pattern with straight, vertical grain lines that enhance stability and aesthetics, commonly found in oak species. Rift sawn wood features a more uniform, linear grain pattern with minimal flecking due to the cutting angle, offering consistent texture ideal for furniture making. Both sawing methods reduce warping but differ significantly in visual appeal, with quarter sawn emphasizing pronounced medullary rays and rift sawn providing a cleaner, tighter grain look.

Stability and Durability Comparison

Quarter sawn wood demonstrates superior stability and resistance to warping due to its grain pattern running mostly perpendicular to the board edges, making it less prone to shrinkage and expansion with humidity changes. Rift sawn wood offers even straighter grain lines but slightly less stability compared to quarter sawn, as it may still experience minor twisting under extreme environmental fluctuations. Choosing quarter sawn lumber ensures enhanced durability for your woodworking projects, especially where long-term dimensional consistency is critical.

Cost Implications: Quarter Sawn vs Rift Sawn

Quarter sawn wood typically incurs higher costs due to increased labor and waste during the cutting process, as it requires precise angling to produce stable, straight grain patterns ideal for fine furniture and flooring. Rift sawn lumber, while also more expensive than plain sawn wood, generally commands a slightly lower price than quarter sawn because it optimizes yield by producing less waste, offering a consistently linear grain favored for its aesthetic appeal and structural integrity. Both sawing methods affect material pricing significantly, with quarter sawn being the premium choice when cost is secondary to durability and unique grain character.

Ideal Applications for Each Cut

Quarter sawn lumber, characterized by its straight grain pattern and increased stability, is ideal for flooring, furniture, and cabinetry where dimensional stability and aesthetic uniformity are critical. Rift sawn wood, known for its consistent tight grain and minimal warping, excels in high-end architectural millwork, musical instruments, and fine furniture requiring clean, linear grain patterns. Both cuts maximize the strength and visual appeal of hardwoods but are chosen based on specific project requirements for grain orientation and durability.

Visual Appeal and Aesthetics

Quarter sawn wood displays a distinctive, straight grain pattern with prominent ray flecks, enhancing visual appeal through its uniform texture and elegant appearance. Rift sawn wood offers a consistently linear grain with minimal flecking, producing a sleek, tailored aesthetic preferred for modern designs. Your choice between these cuts influences the overall look of wood surfaces, balancing between the intricate beauty of quarter sawn and the clean simplicity of rift sawn.

Choosing The Right Sawn Lumber for Your Project

Quarter sawn lumber offers superior stability and a distinctive grain pattern, making it ideal for fine woodworking and furniture projects requiring durability and aesthetic appeal. Rift sawn lumber provides a more uniform, straight grain with minimal warping, perfect for applications needing a clean and consistent appearance, such as flooring and paneling. Consider the specific visual and structural qualities you need for your project when choosing between quarter sawn and rift sawn lumber to ensure optimal performance and beauty.

Quarter sawn vs Rift sawn Infographic

libmatt.com

libmatt.com