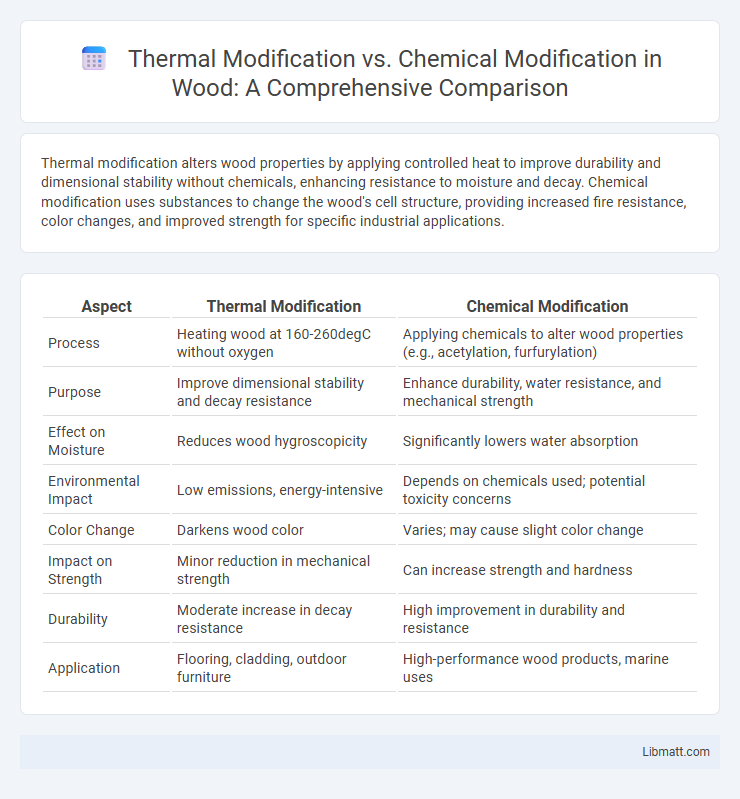

Thermal modification alters wood properties by applying controlled heat to improve durability and dimensional stability without chemicals, enhancing resistance to moisture and decay. Chemical modification uses substances to change the wood's cell structure, providing increased fire resistance, color changes, and improved strength for specific industrial applications.

Table of Comparison

| Aspect | Thermal Modification | Chemical Modification |

|---|---|---|

| Process | Heating wood at 160-260degC without oxygen | Applying chemicals to alter wood properties (e.g., acetylation, furfurylation) |

| Purpose | Improve dimensional stability and decay resistance | Enhance durability, water resistance, and mechanical strength |

| Effect on Moisture | Reduces wood hygroscopicity | Significantly lowers water absorption |

| Environmental Impact | Low emissions, energy-intensive | Depends on chemicals used; potential toxicity concerns |

| Color Change | Darkens wood color | Varies; may cause slight color change |

| Impact on Strength | Minor reduction in mechanical strength | Can increase strength and hardness |

| Durability | Moderate increase in decay resistance | High improvement in durability and resistance |

| Application | Flooring, cladding, outdoor furniture | High-performance wood products, marine uses |

Introduction to Wood Modification Techniques

Wood modification techniques enhance the natural properties of wood for improved durability, stability, and performance. Thermal modification involves heating wood at high temperatures in controlled environments to reduce moisture absorption and increase dimensional stability without chemicals. Chemical modification uses reactive chemicals to alter the wood's cellular structure, enabling enhanced resistance to decay, insects, and environmental factors.

Overview of Thermal Modification

Thermal modification enhances wood durability and dimensional stability by exposing it to high temperatures, typically between 160degC and 260degC, without the use of chemicals. This process reduces the wood's hygroscopicity, improving resistance to decay and weathering, making it ideal for outdoor applications. Your choice of thermal modification offers an environmentally friendly alternative to chemical treatments, preserving the wood's natural appearance and reducing toxic emissions.

Overview of Chemical Modification

Chemical modification involves altering wood properties through the introduction of chemical agents that react with cell wall components, enhancing durability, dimensional stability, and resistance to biological decay. Common treatments include acetylation, which replaces hydroxyl groups with acetyl groups to reduce moisture absorption, and furfurylation, where wood is impregnated with furfuryl alcohol resin to improve hardness and weather resistance. These modifications transform the wood's molecular structure, offering long-lasting performance improvements without significantly affecting mechanical strength.

Key Differences Between Thermal and Chemical Modification

Thermal modification uses heat treatment, typically between 160-260degC, to alter wood's physical properties by reducing moisture content and increasing dimensional stability, while chemical modification involves applying chemicals like furfuryl alcohol or acetic anhydride to change the wood's molecular structure and enhance durability. Thermal modification improves resistance to decay and shrinkage with minimal environmental impact, whereas chemical modification often offers greater resistance to biological degradation but may involve toxic substances and require complex processing. The choice between thermal and chemical modification depends on desired wood performance, environmental considerations, and application requirements.

Impact on Wood Durability and Performance

Thermal modification enhances wood durability by reducing its moisture content and improving resistance to decay and insects, resulting in longer-lasting performance without introducing harmful chemicals. Chemical modification alters the wood's cellular structure using substances like acetyl or furfurylation, significantly increasing dimensional stability and resistance to biological degradation. Your choice between thermal and chemical modification depends on the desired balance of environmental impact, durability, and specific performance requirements.

Environmental and Health Considerations

Thermal modification of wood involves heating at elevated temperatures without chemicals, significantly reducing toxic emissions and chemical residues, making it an environmentally friendly choice. Chemical modification often uses synthetic compounds that can pose risks of harmful off-gassing and require careful handling and disposal to minimize environmental impact. Your decision should consider the lower health risks and reduced environmental footprint associated with thermal modification compared to the potentially hazardous effects of chemical treatments.

Cost Comparison of Modification Methods

Thermal modification generally incurs lower upfront costs compared to chemical modification due to the absence of expensive chemicals and simpler processing equipment, making it more cost-effective for large-scale wood treatment operations. Chemical modification often involves higher material and safety-related expenses, including special handling and disposal of hazardous substances, which increase overall operational costs. Evaluating your project's scale and budget will help determine which modification method offers the best balance between cost and performance.

Suitability for Various Wood Applications

Thermal modification enhances wood's dimensional stability, decay resistance, and suitability for outdoor applications like decking and cladding without introducing harmful chemicals. Chemical modification offers targeted improvements, such as increased fire resistance or pest protection, making it ideal for specialized indoor and industrial wood uses. Understanding your specific application requirements helps determine whether thermal or chemical modification provides the optimal balance of performance and durability.

Recent Advances in Modification Technologies

Recent advances in thermal modification technologies include the development of vacuum thermal treatment and controlled atmosphere processes that enhance wood durability and dimensional stability without toxic chemicals. Chemical modification improvements emphasize bio-based reagents and environmentally friendly catalysts to reduce formaldehyde emissions and improve wood performance. Innovative hybrid approaches combining thermal and chemical modifications demonstrate synergistic effects, leading to superior mechanical properties and increased resistance to biological degradation.

Conclusion: Choosing the Right Modification Method

Thermal modification enhances wood durability and dimensional stability by applying controlled heat, making it ideal for outdoor applications without introducing chemicals. Chemical modification alters wood properties by integrating substances like acetyl or furfuryl, offering improved resistance to moisture and biological decay but may involve more environmental considerations. Selecting the right modification method depends on the specific performance requirements, environmental impact, and cost-effectiveness for the intended use.

Thermal modification vs Chemical modification Infographic

libmatt.com

libmatt.com