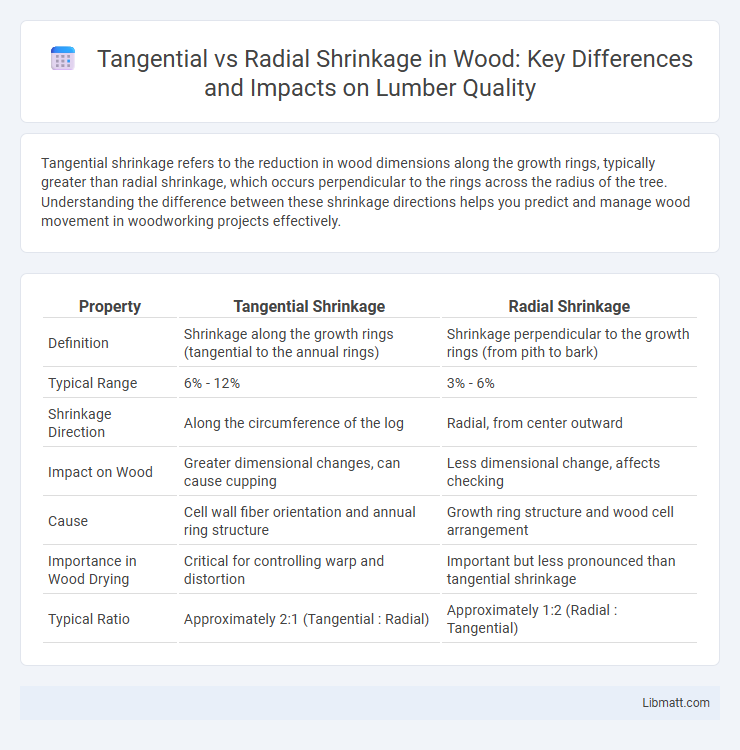

Tangential shrinkage refers to the reduction in wood dimensions along the growth rings, typically greater than radial shrinkage, which occurs perpendicular to the rings across the radius of the tree. Understanding the difference between these shrinkage directions helps you predict and manage wood movement in woodworking projects effectively.

Table of Comparison

| Property | Tangential Shrinkage | Radial Shrinkage |

|---|---|---|

| Definition | Shrinkage along the growth rings (tangential to the annual rings) | Shrinkage perpendicular to the growth rings (from pith to bark) |

| Typical Range | 6% - 12% | 3% - 6% |

| Shrinkage Direction | Along the circumference of the log | Radial, from center outward |

| Impact on Wood | Greater dimensional changes, can cause cupping | Less dimensional change, affects checking |

| Cause | Cell wall fiber orientation and annual ring structure | Growth ring structure and wood cell arrangement |

| Importance in Wood Drying | Critical for controlling warp and distortion | Important but less pronounced than tangential shrinkage |

| Typical Ratio | Approximately 2:1 (Tangential : Radial) | Approximately 1:2 (Radial : Tangential) |

Understanding Wood Shrinkage: Tangential vs Radial

Understanding wood shrinkage requires recognizing the difference between tangential and radial shrinkage, as wood contracts more tangentially (around 6-12%) compared to radially (3-5%). This anisotropic behavior affects woodworking precision, causing warping or cracking if not accounted for during drying or construction. Your projects will benefit from selecting wood and design techniques that consider these shrinkage variations to ensure stability and durability.

Key Differences Between Tangential and Radial Shrinkage

Tangential shrinkage measures the contraction of wood along the growth rings, while radial shrinkage occurs perpendicular to the growth rings, moving outward from the center of the tree. Tangential shrinkage is generally greater than radial shrinkage, which influences wood stability, warping, and dimensional changes during drying. Understanding the contrast between these shrinkage directions helps you select and work with wood more effectively to minimize cracking and distortion.

The Science Behind Wood Shrinkage Directions

Wood shrinkage varies significantly between tangential and radial directions due to the cellular structure and grain orientation. Tangential shrinkage typically exceeds radial shrinkage by approximately 5% to 10%, as the wood fibers contract more along the growth rings rather than across them. This anisotropic behavior is driven by the alignment of cellulose microfibrils and the differential drying rates of the cell walls in each direction.

Factors Influencing Tangential and Radial Shrinkage

Tangential and radial shrinkage in wood are primarily influenced by moisture content changes, wood species, and grain orientation. Hardwood species typically exhibit greater tangential shrinkage compared to radial due to the cellular structure, particularly vessel arrangement and ray cells distribution. Environmental factors such as temperature, humidity fluctuations, and drying rate also significantly impact the extent of shrinkage in these two directions.

Measuring Tangential Shrinkage in Wood

Measuring tangential shrinkage in wood involves assessing dimensional changes parallel to the growth rings, typically greater than radial shrinkage. This measurement is critical for understanding wood stability, affecting how lumber behaves during drying and seasoning. Accurate quantification requires precise tools like calipers or micrometers, tracked before and after drying to calculate shrinkage percentages relative to the green dimension.

Assessing Radial Shrinkage: Methods and Importance

Assessing radial shrinkage involves precise measurements of wood samples taken along the radius from the pith to the bark, using tools like digital calipers or micrometers to monitor dimensional changes during drying. Understanding radial shrinkage is crucial for predicting wood movement, preventing defects such as cracking or warping, and ensuring stability in woodworking projects and structural applications. Your ability to accurately evaluate radial shrinkage directly impacts the quality control processes in lumber processing and the long-term durability of wooden products.

Effects of Shrinkage on Wood Stability and Quality

Tangential shrinkage, which is typically about twice as large as radial shrinkage, significantly affects wood stability by causing more dimensional changes across the grain, leading to warping, cupping, and cracking. Radial shrinkage, though smaller, influences wood quality by contributing to checks and splits along the growth rings. Understanding the balance between tangential and radial shrinkage is crucial for Your woodworking projects to ensure durability and minimize deformation in finished wood products.

Practical Implications for Woodworking

Tangential shrinkage in wood is typically about twice as much as radial shrinkage, leading to significant dimensional changes that can affect woodworking projects. Understanding this difference is crucial for preventing warping and cracking when wood dries, especially in furniture making and cabinetry. You should consider grain orientation and allow for these shrinkage variations to ensure durability and precision in your woodworking creations.

Minimizing Problems from Tangential and Radial Shrinkage

Minimizing problems from tangential and radial shrinkage requires understanding their distinct behaviors in wood drying; tangential shrinkage is typically about twice as large as radial shrinkage, leading to differential stresses and potential warping. Controlling the drying process by reducing moisture gradients and using proper seasoning techniques helps stabilize the wood dimensionally. Your best approach includes selecting wood species with lower shrinkage rates and employing moisture content management to avoid cracking and distortion.

Choosing the Right Wood: Shrinkage Considerations for Projects

Tangential shrinkage typically measures about twice as much as radial shrinkage, making it a critical factor when selecting wood for precision projects. Understanding these dimensional changes helps you choose wood species that minimize warping and cracking, ensuring structural integrity and aesthetic quality. Prioritizing species with lower tangential shrinkage rates improves the durability and stability of your woodworking projects.

Tangential shrinkage vs radial shrinkage Infographic

libmatt.com

libmatt.com