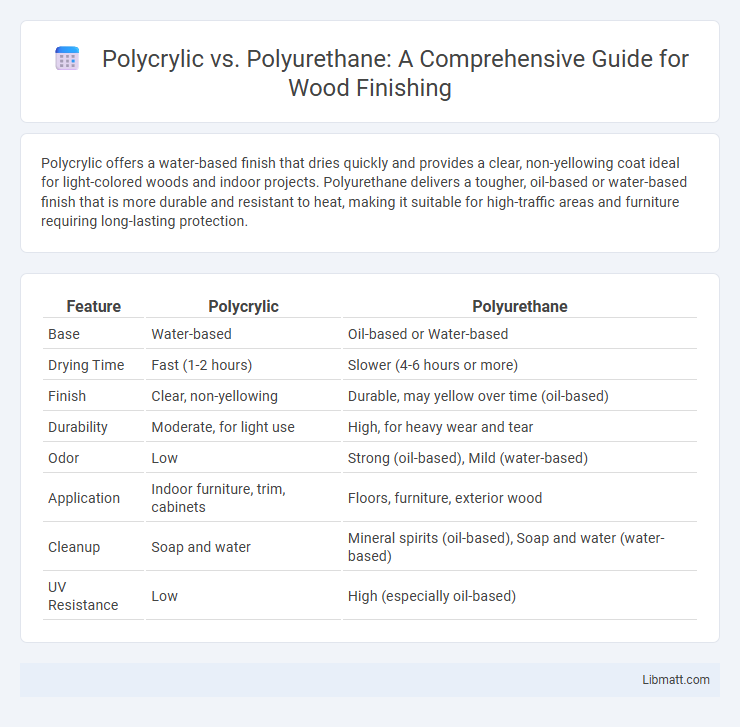

Polycrylic offers a water-based finish that dries quickly and provides a clear, non-yellowing coat ideal for light-colored woods and indoor projects. Polyurethane delivers a tougher, oil-based or water-based finish that is more durable and resistant to heat, making it suitable for high-traffic areas and furniture requiring long-lasting protection.

Table of Comparison

| Feature | Polycrylic | Polyurethane |

|---|---|---|

| Base | Water-based | Oil-based or Water-based |

| Drying Time | Fast (1-2 hours) | Slower (4-6 hours or more) |

| Finish | Clear, non-yellowing | Durable, may yellow over time (oil-based) |

| Durability | Moderate, for light use | High, for heavy wear and tear |

| Odor | Low | Strong (oil-based), Mild (water-based) |

| Application | Indoor furniture, trim, cabinets | Floors, furniture, exterior wood |

| Cleanup | Soap and water | Mineral spirits (oil-based), Soap and water (water-based) |

| UV Resistance | Low | High (especially oil-based) |

Introduction to Polycrylic and Polyurethane

Polycrylic is a water-based protective finish known for its fast drying time and low odor, making it ideal for interior wood surfaces like furniture and trim. Polyurethane, available in both oil-based and water-based forms, offers a more durable and versatile coating suitable for high-traffic areas and surfaces exposed to moisture or heat. Choosing between Polycrylic and Polyurethane depends on your project's requirements for durability, appearance, and environmental considerations.

Composition and Chemical Differences

Polycrylic is a water-based protective finish composed primarily of acrylic polymers, offering low odor and quick drying properties suitable for indoor use. Polyurethane consists of oil-based or water-based resins forming a durable, chemical-resistant layer ideal for high-traffic areas and exterior applications. Your choice between these coatings depends on the desired finish durability, chemical resistance, and environmental factors related to their distinct chemical compositions.

Application Areas: Where to Use Each Finish

Polycrylic is best suited for interior projects such as furniture, cabinetry, and trim because it provides a clear finish that dries quickly and has low odor. Polyurethane excels in high-traffic areas and surfaces exposed to moisture or heat, like floors, countertops, and outdoor furniture, thanks to its superior durability and water resistance. Choosing between the two depends on the project's exposure to wear and environmental factors, with polycrylic favored for light, indoor use and polyurethane preferred for heavy-duty, protective coatings.

Appearance and Finish: Gloss, Satin, Matte Options

Polycrylic offers a clear, non-yellowing finish ideal for light-colored woods with a variety of gloss, satin, and matte sheens that enhance natural beauty without altering color. Polyurethane provides a more durable, water-resistant finish available in gloss, semi-gloss, satin, and matte options, often imparting a slight amber tone to surfaces. You can choose polycrylic for a crystal-clear look or polyurethane for robust protection with diverse sheen levels suited to your project's aesthetic needs.

Durability and Protection Capabilities

Polyurethane offers superior durability and protection against scratches, heat, and chemicals, making it ideal for high-traffic surfaces and heavy-use furniture. Polycrylic, while less durable, provides a clear finish that resists yellowing and is better suited for light-use items and indoor projects. Both finishes protect wood, but polyurethane's robust film delivers longer-lasting defense in demanding environments.

Drying Time and Curing Process

Polycrylic dries faster than polyurethane, typically becoming dry to the touch within 30 minutes to 1 hour, while polyurethane may take 4 to 6 hours or longer depending on the formula. The curing process for polycrylic is shorter, often fully curing within 24 hours, whereas polyurethane can require several days to a week for complete curing, providing its strongest and most durable finish. Your project's timeline and desired durability will determine the best choice based on these drying and curing characteristics.

Ease of Application and Clean-Up

Polycrylic offers easier application with its water-based formula that dries quickly and has low odor, making it ideal for indoor projects and less experienced users. Polyurethane, often oil-based, requires more careful application and has a longer drying time, demanding mineral spirits for clean-up. Water-based Polycrylic allows simple soap and water clean-up, while oil-based polyurethane necessitates solvents, increasing preparation and safety measures.

Environmental Impact and Safety Considerations

Polycrylic is a water-based finish that emits lower levels of volatile organic compounds (VOCs), making it a safer option for indoor use and reducing environmental pollution compared to oil-based polyurethane. Polyurethane, especially oil-based variants, has a higher VOC content, contributing to air quality concerns and requiring careful ventilation during application. Both finishes require proper disposal, but polycrylic's water solubility enhances cleanup and reduces hazardous waste generation.

Cost Comparison: Polycrylic vs Polyurethane

Polycrylic typically costs between $15 and $25 per quart, making it more affordable for small projects or indoor use compared to polyurethane, which ranges from $20 to $40 per quart depending on whether it is oil-based or water-based. Polyurethane's higher price reflects its superior durability and resistance to moisture and heat, especially in oil-based formulations, which can be essential for high-traffic areas or outdoor applications. Choosing between polycrylic and polyurethane ultimately depends on the budget constraints and the level of protection required for the finished surface.

Choosing the Right Finish for Your Project

Polycrylic offers a water-based finish ideal for light-colored woods and interior projects due to its low odor and quick drying time. Polyurethane provides a more durable, oil-based or water-based option suited for high-traffic areas and exterior surfaces, offering superior resistance to heat, chemicals, and wear. Your choice depends on the project's location, type of wood, and desired durability to ensure the best protection and appearance.

Polycrylic vs Polyurethane Infographic

libmatt.com

libmatt.com