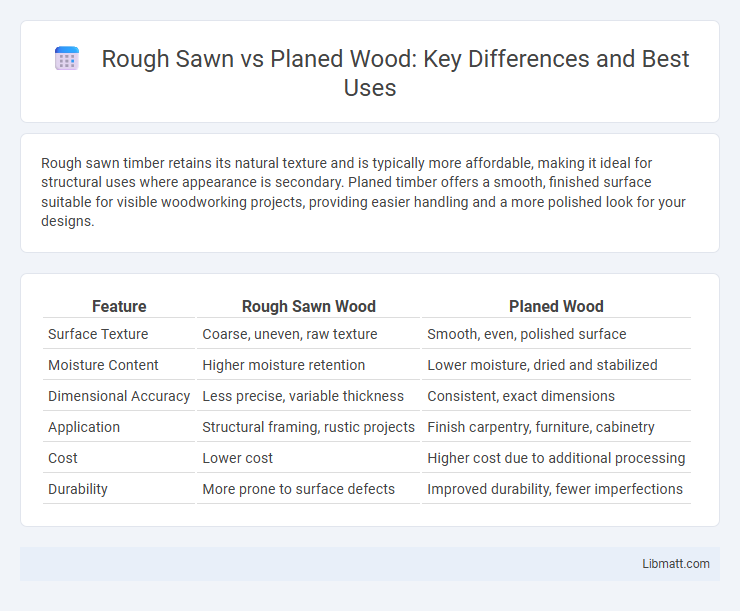

Rough sawn timber retains its natural texture and is typically more affordable, making it ideal for structural uses where appearance is secondary. Planed timber offers a smooth, finished surface suitable for visible woodworking projects, providing easier handling and a more polished look for your designs.

Table of Comparison

| Feature | Rough Sawn Wood | Planed Wood |

|---|---|---|

| Surface Texture | Coarse, uneven, raw texture | Smooth, even, polished surface |

| Moisture Content | Higher moisture retention | Lower moisture, dried and stabilized |

| Dimensional Accuracy | Less precise, variable thickness | Consistent, exact dimensions |

| Application | Structural framing, rustic projects | Finish carpentry, furniture, cabinetry |

| Cost | Lower cost | Higher cost due to additional processing |

| Durability | More prone to surface defects | Improved durability, fewer imperfections |

Introduction to Rough Sawn and Planed Lumber

Rough sawn lumber features a coarse, textured surface directly from the sawmill, retaining natural wood characteristics ideal for rustic projects and structural use. Planed lumber undergoes additional processing, resulting in smooth, uniform surfaces that are ready for finishing and precise construction. Understanding these differences helps you select the right type of wood for your specific building or woodworking needs.

Defining Rough Sawn Lumber

Rough sawn lumber refers to wood that has been cut from logs using a sawmill but remains untreated and unplaned, preserving its coarse, textured surface. This type of lumber typically retains its natural edges and roughness due to the absence of sanding or smoothing processes, making it suitable for rustic or structural applications where natural aesthetics and strength are prioritized. Rough sawn lumber often has slightly larger dimensions than planed wood because planing removes a thin layer from the surface to create smoothness and uniformity.

Understanding Planed Lumber

Planed lumber, also known as surfaced or S2S (surfaced two sides), is wood that has been smoothed and dimensionally standardized by passing it through a planer, resulting in a uniform thickness and a smooth surface ideal for precise woodworking projects. Unlike rough sawn lumber, which retains the natural texture and inconsistent dimensions from initial milling, planed lumber offers better stability, easier finishing, and improved fit in construction or furniture making. Understanding planed lumber's consistent size and smooth surface helps optimize material usage and enhances the aesthetic and structural quality of the final product.

Key Differences Between Rough Sawn and Planed

Rough sawn wood features a textured, uneven surface directly from the sawmill, retaining its natural, rustic appearance and typically requiring further finishing. Planed wood undergoes a smoothing process that removes saw marks, producing a uniform, polished surface ideal for furniture and cabinetry. Your choice between rough sawn and planed depends on the desired aesthetic and the level of preparation needed for your project.

Pros and Cons of Rough Sawn Lumber

Rough sawn lumber offers superior grip and a rustic aesthetic, making it ideal for outdoor and heavy-duty projects where texture matters. It tends to be more affordable and retains more natural moisture, which can reduce warping during drying but requires extra finishing work. Your choice depends on whether you prioritize cost, durability, or ease of handling for your woodworking needs.

Advantages and Disadvantages of Planed Lumber

Planed lumber offers a smooth, finished surface that is easier to paint, stain, and handle, making it ideal for visible applications like furniture and interior trim. The uniform thickness and precise dimensions reduce sanding and fitting time but come at a higher cost compared to rough sawn lumber. You benefit from planed lumber's aesthetic appeal and ease of use, though it may lack the rustic texture and affordability found in rough sawn alternatives.

Common Uses for Rough Sawn Wood

Rough sawn wood is commonly used in construction projects requiring a rustic or natural appearance, such as fencing, decking, and outdoor landscaping. Its textured surface provides better grip and traction, making it ideal for walkways and utility poles. Additionally, rough sawn lumber is preferred for structural applications where aesthetic finish is not critical but strength and durability are essential.

Typical Applications of Planed Wood

Planed wood, with its smooth surface and consistent thickness, is typically used in interior applications such as furniture making, cabinetry, and decorative paneling. Its refined finish also makes it ideal for trim work, molding, and flooring where aesthetic appeal and precise fitting are critical. The planing process removes surface imperfections, ensuring better paint or stain adhesion for high-quality finishes.

Choosing the Right Lumber for Your Project

Choosing the right lumber for your project involves understanding the differences between rough sawn and planed wood. Rough sawn lumber retains its natural, textured surface and is ideal for rustic or outdoor projects requiring enhanced grip and a traditional look. Planed wood offers a smooth, uniform finish perfect for furniture or interior work where precise dimensions and aesthetics are critical.

Rough Sawn vs Planed: Which Is Best for You?

Rough sawn wood offers a textured, rustic appearance ideal for projects emphasizing natural character and grip, while planed wood provides a smooth, even surface perfect for precise finishes and easy painting. Your choice depends on the desired aesthetic and functional requirements of your project, with rough sawn wood excelling in durability and planed wood favored for refined detail work. Understanding these differences ensures you select the best material to enhance both the look and performance of your construction or woodworking project.

Rough sawn vs planed Infographic

libmatt.com

libmatt.com