Wood screws feature thicker shafts and coarser threads designed for strong grip in solid wood, while drywall screws have thinner, sharper threads optimized for fastening drywall sheets to wood or metal studs. Choosing the right screw ensures your project's stability and prevents issues like stripped holes or weak joints.

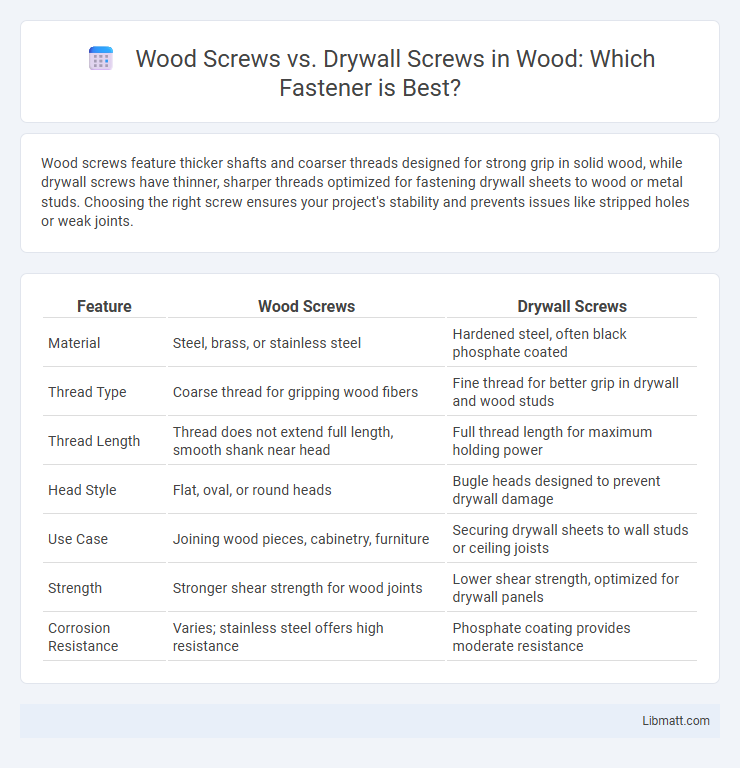

Table of Comparison

| Feature | Wood Screws | Drywall Screws |

|---|---|---|

| Material | Steel, brass, or stainless steel | Hardened steel, often black phosphate coated |

| Thread Type | Coarse thread for gripping wood fibers | Fine thread for better grip in drywall and wood studs |

| Thread Length | Thread does not extend full length, smooth shank near head | Full thread length for maximum holding power |

| Head Style | Flat, oval, or round heads | Bugle heads designed to prevent drywall damage |

| Use Case | Joining wood pieces, cabinetry, furniture | Securing drywall sheets to wall studs or ceiling joists |

| Strength | Stronger shear strength for wood joints | Lower shear strength, optimized for drywall panels |

| Corrosion Resistance | Varies; stainless steel offers high resistance | Phosphate coating provides moderate resistance |

Introduction to Wood Screws and Drywall Screws

Wood screws feature coarse threads and a tapered shaft designed to securely fasten wood pieces with strong holding power in wood fibers. Drywall screws have finer threads and a sharper point, specifically engineered to attach drywall panels to wooden or metal studs without damaging the gypsum core. Both screw types differ in thread design, length, and coating to suit their unique applications in construction and carpentry.

Material Composition and Strength

Wood screws are typically made from hardened steel or brass, providing durability and resistance to corrosion especially in outdoor or heavy-duty wood applications. Drywall screws are usually manufactured from hardened steel with a phosphate coating, designed specifically for attaching drywall to wooden or metal studs and offering adequate strength without much corrosion resistance. The key difference lies in wood screws having thicker shafts and coarser threads for better grip in wood fibers, while drywall screws have finer threads optimized for drywall paper and studs.

Design Differences: Threads and Points

Wood screws feature coarse threads that extend partially up the shaft, designed to grip wood fibers tightly and reduce splitting, with a sharp, tapered point for easy insertion into wooden materials. Drywall screws have finer, more closely spaced threads that run the entire length of the screw, providing better holding power in gypsum board and metal studs, and a bugle-shaped head to prevent tearing the drywall paper. Understanding these design differences helps you choose the right screw for secure fastening in your construction or repair projects.

Common Applications

Wood screws are commonly used in woodworking projects, furniture assembly, and cabinetry due to their coarse threads designed for gripping wood fibers securely. Drywall screws feature finer threads optimized for fastening drywall sheets to metal or wooden studs, ensuring strong but less intrusive holding power. Choosing the right screw for your application enhances structural integrity and prevents material damage.

Load-Bearing Capacity

Wood screws offer superior load-bearing capacity due to their thicker shafts and deeper threads, making them ideal for structural woodworking projects where strength is critical. Drywall screws have finer threads and thinner shafts, designed primarily for attaching drywall sheets to wooden or metal studs, resulting in lower load resistance. Choosing wood screws ensures your project can handle heavier loads and maintain long-term durability under stress.

Installation Techniques

Wood screws require pre-drilling pilot holes to prevent splitting and ensure a tight fit in hardwood or softwood surfaces, using a screwdriver or drill with variable torque settings for optimal control. Drywall screws typically feature a bugle head and sharp point, allowing direct penetration into drywall and metal studs without pre-drilling, and are installed using a drywall gun or drill with a clutch to avoid surface damage. Proper installation techniques for each screw type enhance holding strength and prevent material damage during construction or renovation projects.

Pros and Cons of Wood Screws

Wood screws offer superior holding power and are specifically designed for wood materials, featuring coarse threads that grip wood fibers effectively, making them ideal for woodworking projects requiring strong joints. They are easier to remove and less prone to stripping compared to drywall screws but tend to be more expensive and slower to install. Your choice should consider whether you need durability and reusability or cost-effectiveness and installation speed.

Pros and Cons of Drywall Screws

Drywall screws offer excellent holding power and are designed specifically for fastening drywall to wood or metal studs, with sharp tips that reduce splitting and ease installation. They tend to have a more brittle, thinner shaft compared to wood screws, which makes them less suitable for heavy-duty woodworking or outdoor applications due to lower shear strength and corrosion resistance. Their cost-effectiveness and availability in various lengths and coatings make drywall screws ideal for interior drywall projects but less durable for structural or weather-exposed uses.

Cost Comparison

Wood screws typically cost more than drywall screws due to their specialized design and higher quality materials, ensuring better durability and grip in wood applications. Drywall screws are generally cheaper, making them a cost-effective choice for hanging gypsum boards but less suitable for heavy-duty wood projects. When planning Your budget, consider the price difference alongside the intended use to ensure you select the most economical and functional option.

Choosing the Right Screw for Your Project

Wood screws feature coarse threads and a tapered shaft designed for strong grip in wood fibers, making them ideal for woodworking projects requiring durability and load-bearing capacity. Drywall screws possess finer threads and a thinner, hardened shaft to penetrate drywall studs without damaging the gypsum board, ensuring secure mounting of drywall panels. Selecting the right screw depends on material type and project requirements; use wood screws for hardwood or softwood construction and drywall screws for sheetrock installation and light framing.

Wood screws vs drywall screws Infographic

libmatt.com

libmatt.com