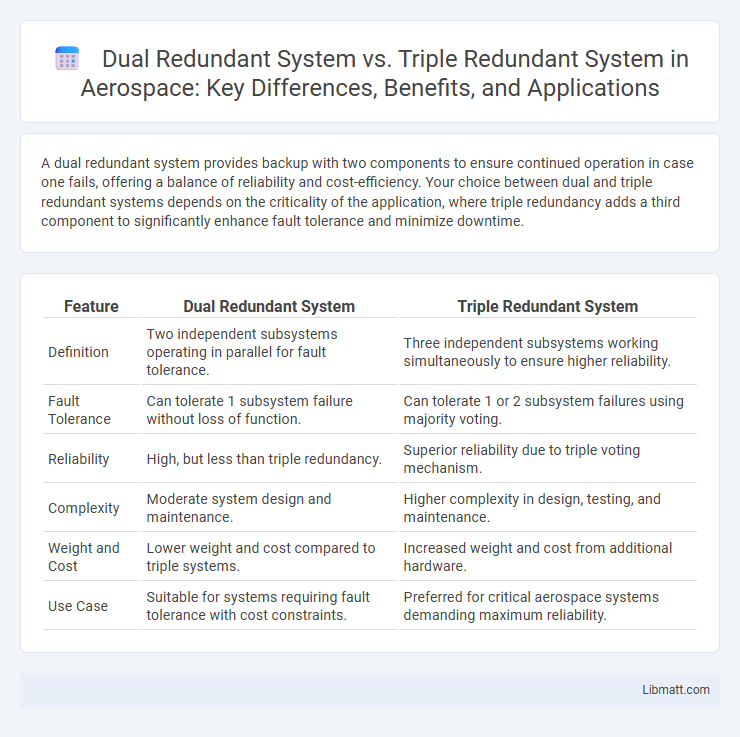

A dual redundant system provides backup with two components to ensure continued operation in case one fails, offering a balance of reliability and cost-efficiency. Your choice between dual and triple redundant systems depends on the criticality of the application, where triple redundancy adds a third component to significantly enhance fault tolerance and minimize downtime.

Table of Comparison

| Feature | Dual Redundant System | Triple Redundant System |

|---|---|---|

| Definition | Two independent subsystems operating in parallel for fault tolerance. | Three independent subsystems working simultaneously to ensure higher reliability. |

| Fault Tolerance | Can tolerate 1 subsystem failure without loss of function. | Can tolerate 1 or 2 subsystem failures using majority voting. |

| Reliability | High, but less than triple redundancy. | Superior reliability due to triple voting mechanism. |

| Complexity | Moderate system design and maintenance. | Higher complexity in design, testing, and maintenance. |

| Weight and Cost | Lower weight and cost compared to triple systems. | Increased weight and cost from additional hardware. |

| Use Case | Suitable for systems requiring fault tolerance with cost constraints. | Preferred for critical aerospace systems demanding maximum reliability. |

Introduction to Redundant Systems

Redundant systems ensure continuous operation by duplicating critical components to prevent failure impacts. A dual redundant system involves two identical units working in parallel, providing backup if one fails, while a triple redundant system uses three units with majority voting to enhance fault tolerance and reliability. Your choice between dual and triple redundancy depends on the required level of safety, system complexity, and cost considerations.

What is a Dual Redundant System?

A Dual Redundant System consists of two independent components or subsystems operating simultaneously to ensure continuous functionality in case one fails, enhancing system reliability and fault tolerance. It is widely used in critical applications like aerospace, telecommunications, and data centers to prevent downtime and data loss. This system architecture balances cost and risk by providing backup without the complexity of triple redundancy.

What is a Triple Redundant System?

A Triple Redundant System employs three independent components performing the same function to ensure higher reliability and fault tolerance compared to a Dual Redundant System, which uses only two. This configuration allows the system to continue operating correctly even if one component fails, by using a majority voting mechanism among the three outputs. Your critical applications benefit from Triple Redundant Systems by minimizing downtime and increasing overall system safety.

Key Differences Between Dual and Triple Redundancy

Dual redundant systems use two independent components to provide backup, ensuring system reliability by allowing one component to fail without causing total system failure. Triple redundant systems, on the other hand, incorporate three components and use majority voting to identify and isolate faults, significantly increasing fault tolerance and system availability. Your choice between dual and triple redundancy depends on the required level of reliability and fault tolerance for critical applications.

Reliability in Dual vs Triple Redundant Systems

Dual redundant systems offer improved reliability by providing a backup component that takes over if the primary fails, reducing the risk of total system failure. Triple redundant systems enhance reliability further by using three parallel components and majority voting, ensuring continuous operation even if one component malfunctions. Your choice impacts system availability, with triple redundancy generally delivering higher fault tolerance and minimized downtime compared to dual redundancy.

Cost Implications: Dual vs Triple Redundancy

Dual redundant systems typically incur lower upfront and maintenance costs than triple redundant systems due to fewer hardware components and simpler integration requirements. Triple redundancy provides higher fault tolerance and system reliability, which can justify the increased expenses in critical applications where downtime is unacceptable. Evaluating your specific operational needs and budget constraints will help determine whether the added investment in triple redundancy offers sufficient value over dual redundancy.

Application Areas for Dual Redundant Systems

Dual redundant systems are widely applied in aerospace control systems, automotive safety features, and industrial automation where fault tolerance is essential but cost and complexity must be balanced. These systems ensure continuous operation by switching to the backup component upon failure, making them ideal for real-time applications like aircraft flight controls and factory robotics. Their simpler architecture compared to triple redundant systems reduces maintenance needs while still providing reliable fault detection and mitigation.

Use Cases for Triple Redundant Systems

Triple redundant systems are essential in aerospace, nuclear power plants, and medical devices where failure risks must be minimized for safety and reliability. They provide continuous fault tolerance by allowing two components to fail while maintaining system operation, which is critical in mission-critical applications. These systems are favored in environments requiring high availability and error correction through majority voting mechanisms.

Choosing the Right Redundancy Level

Choosing the right redundancy level depends on system criticality, cost constraints, and desired reliability metrics, with dual redundant systems offering basic fault tolerance by supporting one failure without loss of function. Triple redundant systems provide enhanced fault tolerance by allowing continuous operation despite two concurrent failures, ideal for mission-critical applications requiring near-zero downtime. Risk assessment and failure impact analysis guide the decision, balancing performance needs with budget and maintenance complexity.

Conclusion: Dual or Triple Redundancy?

Choosing between dual redundant and triple redundant systems depends on your critical need for reliability versus cost and complexity. Dual redundancy offers sufficient fault tolerance for many applications, reducing downtime with moderate investment, while triple redundancy provides higher fault tolerance and system availability, minimizing risk in mission-critical environments. Your decision should balance the acceptable level of risk, budget constraints, and the specific demands of your operational context.

Dual Redundant System vs Triple Redundant System Infographic

libmatt.com

libmatt.com