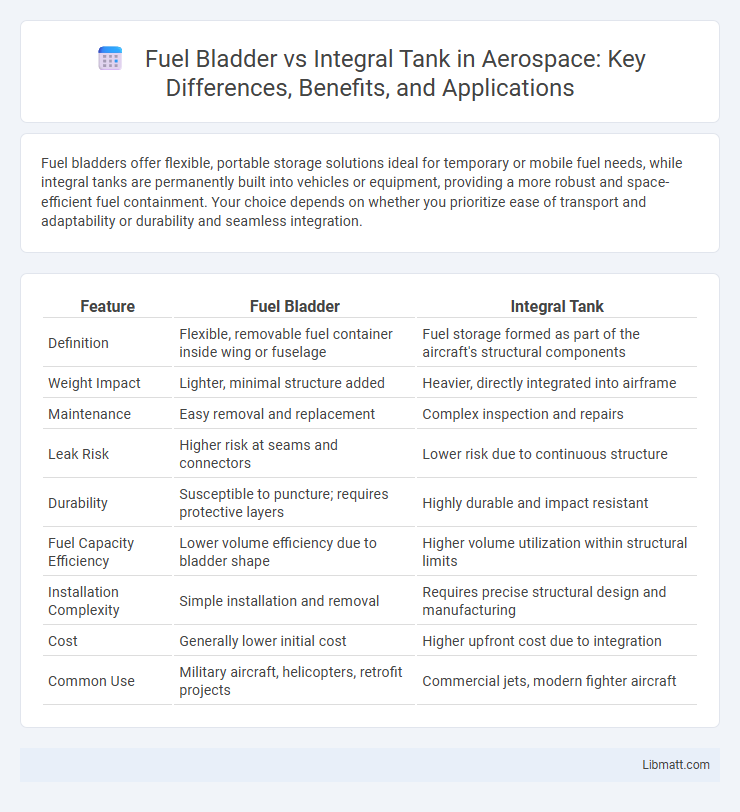

Fuel bladders offer flexible, portable storage solutions ideal for temporary or mobile fuel needs, while integral tanks are permanently built into vehicles or equipment, providing a more robust and space-efficient fuel containment. Your choice depends on whether you prioritize ease of transport and adaptability or durability and seamless integration.

Table of Comparison

| Feature | Fuel Bladder | Integral Tank |

|---|---|---|

| Definition | Flexible, removable fuel container inside wing or fuselage | Fuel storage formed as part of the aircraft's structural components |

| Weight Impact | Lighter, minimal structure added | Heavier, directly integrated into airframe |

| Maintenance | Easy removal and replacement | Complex inspection and repairs |

| Leak Risk | Higher risk at seams and connectors | Lower risk due to continuous structure |

| Durability | Susceptible to puncture; requires protective layers | Highly durable and impact resistant |

| Fuel Capacity Efficiency | Lower volume efficiency due to bladder shape | Higher volume utilization within structural limits |

| Installation Complexity | Simple installation and removal | Requires precise structural design and manufacturing |

| Cost | Generally lower initial cost | Higher upfront cost due to integration |

| Common Use | Military aircraft, helicopters, retrofit projects | Commercial jets, modern fighter aircraft |

Introduction to Fuel Bladders and Integral Tanks

Fuel bladders and integral tanks serve as crucial fuel storage solutions, with fuel bladders offering flexible, portable options made from durable materials ideal for temporary or emergency use. Integral tanks are built directly into the structure of vehicles or equipment, providing permanent, secure fuel storage that optimizes space and weight distribution. Understanding these differences helps you select the right solution based on your specific fuel storage and operational needs.

Definition and Design Differences

Fuel bladders are flexible, collapsible containers made from durable materials like polyurethane or rubber, designed for temporary or portable fuel storage. Integral tanks are rigid, permanently installed fuel tanks integrated within the aircraft or vehicle structure, often fabricated from metal or composite materials for enhanced strength and durability. The primary design difference lies in flexibility and installation; bladders offer adaptability and ease of removal, while integral tanks provide structural support and long-term fuel containment.

Material Composition and Durability

Fuel bladders are typically made from multi-layered synthetic materials such as polyurethane, nitrile rubber, or PVC, offering high flexibility and chemical resistance, which makes them ideal for temporary or transport fuel storage. Integral tanks are constructed from rigid materials like aluminum, steel, or composite fibers, providing superior structural integrity and long-term durability under harsh operating conditions. The choice between bladders and integral tanks depends largely on mission requirements, where bladders excel in portability and damage resilience, while integral tanks offer enhanced protection against environmental stresses and mechanical impact.

Installation Procedures and Requirements

Fuel bladders offer flexible installation with minimal structural modifications, allowing for quick setup in confined or irregular spaces. Integral tanks require precision engineering and fabrication directly into the vehicle or equipment chassis, demanding more extensive labor and compliance with strict safety standards. Installation of integral tanks often involves custom welding and reinforcement, whereas fuel bladders rely on secure mounting and sealing procedures to prevent leaks and ensure durability.

Weight and Space Efficiency

Fuel bladders offer superior weight savings and space efficiency compared to integral tanks due to their flexible, lightweight materials and ability to conform to available spaces. Integral tanks, made from rigid materials, add structural weight and require more precise installation volume, often limiting usable capacity and increasing aircraft weight. Optimizing aircraft design for fuel storage favors bladders when minimizing weight and maximizing space utilization is critical.

Maintenance and Inspection Considerations

Fuel bladders require regular inspections for leaks, punctures, and material degradation due to their flexible construction, demanding more frequent maintenance compared to integral tanks. Integral tanks, being rigid and built into the aircraft structure, typically offer easier accessibility for inspection and maintenance, reducing downtime and ensuring structural integrity. You should consider your operational environment and maintenance resources when choosing between these fuel storage options.

Safety and Leak Prevention

Fuel bladders offer superior leak prevention due to their flexible, puncture-resistant materials that minimize the risk of fuel spills during impact or movement. Integral tanks, being rigid and fixed within the vehicle structure, have a higher chance of developing cracks or fractures under stress, posing greater safety risks. Bladders also feature self-sealing layers that enhance containment, significantly reducing environmental hazards compared to traditional integral tanks.

Cost Comparison: Initial and Long-term

Fuel bladders offer a lower initial cost due to their lightweight, flexible materials and simpler installation compared to integral tanks, which require extensive integration into a vehicle or vessel structure. Over the long term, integral tanks generally provide greater durability and reduced maintenance expenses, as they are less prone to damage and leaks than fuel bladders that may require periodic replacement or repairs. Your choice between these two options should consider the balance between upfront investment and ongoing operational costs based on specific usage conditions.

Applications Across Industries

Fuel bladders offer flexible and portable fuel storage solutions ideal for military operations, construction sites, and emergency response where rapid deployment and mobility are crucial. Integral tanks, integrated into vehicle or equipment structures, provide durable, space-efficient fuel containment commonly used in aerospace, automotive, and marine industries requiring long-term reliability and optimized design. Your choice depends on the specific industry demands for portability, durability, and installation constraints.

Choosing the Right Solution for Your Needs

Fuel bladders offer flexibility and portability, making them ideal for temporary or mobile fuel storage, while integral tanks provide durability and permanent installation benefits for vehicles or equipment. Selecting the appropriate solution depends on factors like storage capacity, environmental conditions, and usage frequency. Assessing your operational requirements ensures optimal fuel management and safety compliance.

fuel bladder vs integral tank Infographic

libmatt.com

libmatt.com