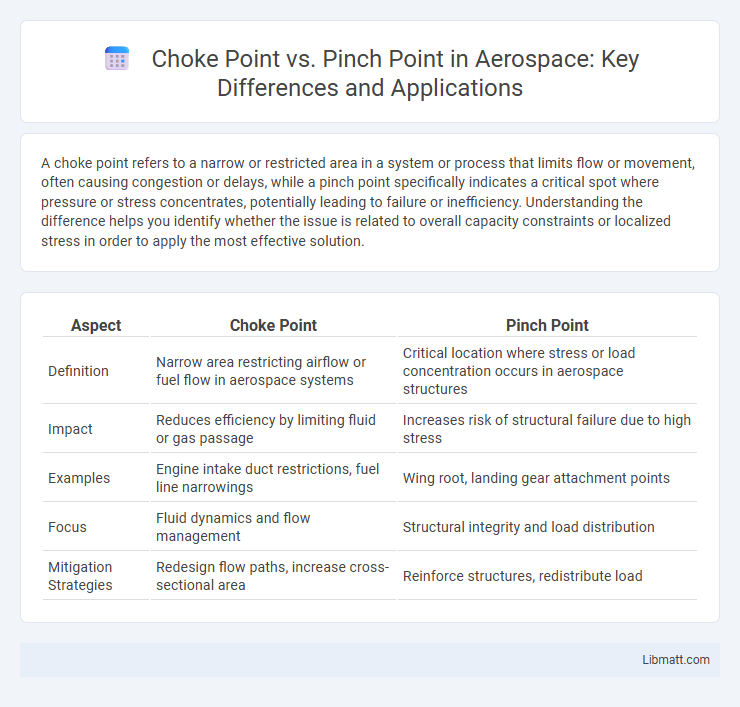

A choke point refers to a narrow or restricted area in a system or process that limits flow or movement, often causing congestion or delays, while a pinch point specifically indicates a critical spot where pressure or stress concentrates, potentially leading to failure or inefficiency. Understanding the difference helps you identify whether the issue is related to overall capacity constraints or localized stress in order to apply the most effective solution.

Table of Comparison

| Aspect | Choke Point | Pinch Point |

|---|---|---|

| Definition | Narrow area restricting airflow or fuel flow in aerospace systems | Critical location where stress or load concentration occurs in aerospace structures |

| Impact | Reduces efficiency by limiting fluid or gas passage | Increases risk of structural failure due to high stress |

| Examples | Engine intake duct restrictions, fuel line narrowings | Wing root, landing gear attachment points |

| Focus | Fluid dynamics and flow management | Structural integrity and load distribution |

| Mitigation Strategies | Redesign flow paths, increase cross-sectional area | Reinforce structures, redistribute load |

Introduction to Choke Points and Pinch Points

Choke points are narrow passages or locations where flow is restricted, causing potential bottlenecks in transportation, communication, or logistics networks. Pinch points refer to critical areas in processes or systems where capacity is limited, restricting overall throughput and efficiency. Understanding these terms helps you identify vulnerabilities in supply chains, infrastructure, or workflows to improve performance and risk management.

Defining Choke Points

Choke points are strategic narrow passages or locations where the flow of traffic, goods, or information is restricted, creating potential bottlenecks that can significantly impact supply chains or military movements. Unlike pinch points, which refer to any constrained or vulnerable area, choke points specifically represent critical junctures whose control or disruption can affect large-scale operational efficiency. Understanding choke points is essential for managing risks and ensuring the stability of your logistical or strategic plans.

Defining Pinch Points

Pinch points are specific locations where a fluid flow or a process is constricted, causing a reduction in its capacity or speed, often critical in engineering and safety contexts. Unlike choke points, which refer broadly to narrowing or bottlenecks in various systems, pinch points specifically highlight areas where pressure or force concentrates, making them crucial for hazard identification. Understanding pinch points helps you mitigate risks in mechanical designs and ensure smooth operational flow.

Key Differences Between Choke Points and Pinch Points

Choke points refer to narrow passages or strategic locations where movement or flow is restricted, often impacting transportation, supply chains, or military operations. Pinch points describe specific areas in workflows, processes, or physical spaces where congestion or obstruction occurs, causing delays or bottlenecks. The key difference lies in choke points being broader strategic or geographic constraints, whereas pinch points are localized, operational, or tactical bottlenecks affecting efficiency.

Common Industries Impacted by Choke and Pinch Points

Choke points and pinch points significantly impact manufacturing, construction, and supply chain industries by restricting flow and reducing operational efficiency. In logistics and transportation, these bottlenecks delay shipments and increase costs due to limited capacity in critical transit areas. Energy and chemical sectors also face risks at choke and pinch points where fluid dynamics and pressure constraints can hinder processing and safety.

Real-World Examples of Choke Points

Choke points are critical narrow passages like the Strait of Hormuz or the Panama Canal, where maritime traffic is heavily concentrated and vulnerable to disruption. These strategic locations control significant portions of global trade, with the Strait of Hormuz handling nearly 20% of the world's oil shipments daily. Understanding such choke points helps you assess geopolitical risks and the security of international supply chains.

Real-World Applications of Pinch Points

Pinch points are critical in workplace safety, particularly in environments involving machinery or conveyor belts where two objects move toward each other, creating a hazardous zone that can trap or crush body parts. Unlike choke points, which primarily describe strategic or logistical bottlenecks, pinch points emphasize physical risk locations requiring strict safety protocols, such as guards or warning signs. Understanding your environment's pinch points ensures targeted prevention measures, reducing injury risks in industrial, construction, and manufacturing settings.

Addressing Bottlenecks: Strategies for Choke Points vs Pinch Points

Choke points require targeted strategies that focus on increasing capacity and streamlining flow to alleviate severe constraints, often involving infrastructure upgrades or process redesign. Pinch points, while less severe, benefit from optimization techniques such as balancing workloads and improving coordination to prevent cascading delays. Your ability to distinguish between these bottlenecks enables tailored interventions that enhance overall system efficiency and reduce operational disruptions.

Benefits of Identifying Choke and Pinch Points in Operations

Identifying choke points and pinch points in operations enhances process efficiency by pinpointing critical bottlenecks that restrict workflow and resource allocation. You gain the ability to implement targeted improvements that reduce delays, increase throughput, and optimize overall productivity. Recognizing these constraints supports proactive decision-making, leading to cost savings and improved operational resilience.

Conclusion: Optimizing Processes by Managing Critical Points

Choke points and pinch points both represent critical junctures where flow or progress can be restricted, impacting overall efficiency. Understanding these bottlenecks enables targeted interventions to streamline operations, reduce delays, and optimize resource allocation. Your ability to identify and manage these key areas ensures smoother processes and improved productivity across systems.

choke point vs pinch point Infographic

libmatt.com

libmatt.com