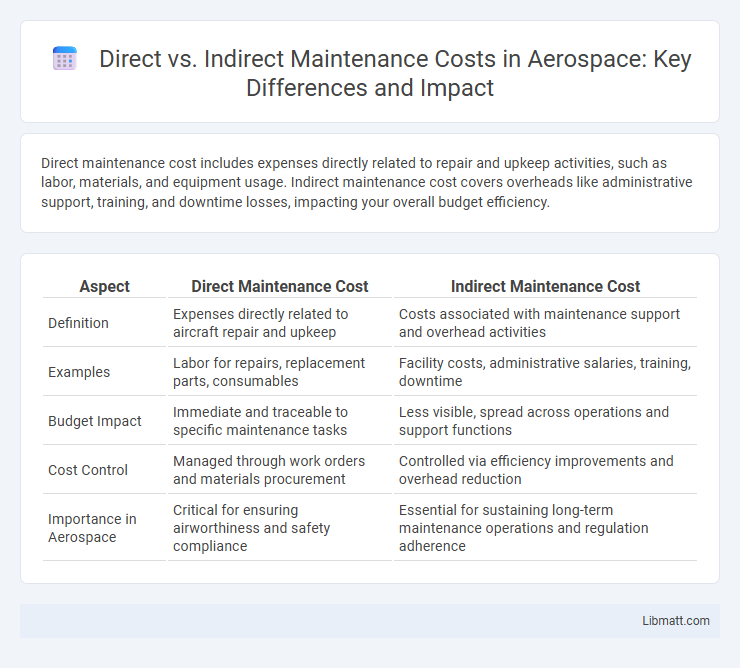

Direct maintenance cost includes expenses directly related to repair and upkeep activities, such as labor, materials, and equipment usage. Indirect maintenance cost covers overheads like administrative support, training, and downtime losses, impacting your overall budget efficiency.

Table of Comparison

| Aspect | Direct Maintenance Cost | Indirect Maintenance Cost |

|---|---|---|

| Definition | Expenses directly related to aircraft repair and upkeep | Costs associated with maintenance support and overhead activities |

| Examples | Labor for repairs, replacement parts, consumables | Facility costs, administrative salaries, training, downtime |

| Budget Impact | Immediate and traceable to specific maintenance tasks | Less visible, spread across operations and support functions |

| Cost Control | Managed through work orders and materials procurement | Controlled via efficiency improvements and overhead reduction |

| Importance in Aerospace | Critical for ensuring airworthiness and safety compliance | Essential for sustaining long-term maintenance operations and regulation adherence |

Introduction to Direct and Indirect Maintenance Costs

Direct maintenance costs encompass expenses directly tied to repairing and servicing equipment, including labor, parts, and materials. Indirect maintenance costs refer to overhead expenses such as administrative support, downtime losses, and training, which are not directly linked to specific repair tasks. Understanding the distinction between these costs helps you allocate resources efficiently and optimize overall maintenance budgeting.

Defining Direct Maintenance Costs

Direct maintenance costs refer to expenses directly attributable to the repair and upkeep of equipment or facilities, including labor, materials, and replacement parts. These costs are easily traceable to specific maintenance activities and are essential for budgeting and cost control in maintenance management. Understanding your direct maintenance costs helps optimize spending and improve operational efficiency.

Understanding Indirect Maintenance Costs

Indirect maintenance costs include expenses that are not directly tied to the repair or upkeep of equipment, such as administrative overhead, downtime losses, and training expenses. Understanding these costs is crucial because they often represent a significant portion of total maintenance expenditures and impact overall operational efficiency. Your ability to identify and manage indirect maintenance costs can lead to more accurate budgeting and improved resource allocation.

Key Differences Between Direct and Indirect Maintenance Costs

Direct maintenance costs include expenses directly attributable to repair and upkeep activities such as labor, materials, and replacement parts, providing clear visibility on specific asset-related spending. Indirect maintenance costs encompass overhead costs like administrative salaries, training, and utility expenses that support maintenance operations but cannot be traced to a single asset. Understanding these key differences helps you allocate budgets more accurately and optimize overall maintenance strategies.

Examples of Direct Maintenance Costs

Direct maintenance costs include expenses directly linked to repair and upkeep activities such as labor wages for technicians, purchase of spare parts, and costs of consumables like lubricants and cleaning materials. These costs are easily traceable to specific machinery or equipment, such as replacing a faulty bearing or routine oil changes for a production line motor. Tracking direct maintenance costs helps organizations accurately budget for equipment maintenance and evaluate the efficiency of maintenance operations.

Examples of Indirect Maintenance Costs

Indirect maintenance costs include expenses such as downtime losses, reduced equipment efficiency, and administrative overhead related to maintenance planning and supervision. These costs also cover training personnel, maintaining spare parts inventory, and quality control activities that do not directly involve repair tasks. Indirect costs often surpass direct costs by impacting production schedules and overall facility performance.

Impact of Maintenance Cost Types on Budgeting

Direct maintenance costs, including labor, parts, and materials, are straightforward to track, enabling precise budget allocation for scheduled repairs and replacements. Indirect maintenance costs, such as downtime, lost productivity, and administrative overhead, are less visible but can significantly inflate overall maintenance expenses and complicate budget forecasting. Accurate budgeting requires integrating both cost types to avoid underestimating the financial impact of maintenance activities on operational efficiency.

Strategies to Manage Direct and Indirect Maintenance Costs

Effective strategies to manage direct maintenance costs include scheduling preventive maintenance, utilizing predictive analytics, and optimizing spare parts inventory to reduce labor and material expenses. Indirect maintenance costs can be controlled by improving equipment reliability through root cause analysis, implementing employee training programs to enhance workforce efficiency, and leveraging technology for better maintenance planning and downtime reduction. Combining these approaches increases overall cost efficiency and extends asset lifecycles.

Importance of Accurate Cost Allocation in Maintenance

Accurate cost allocation between direct maintenance costs, such as labor and materials used for specific repairs, and indirect maintenance costs, like supervision and administrative expenses, is critical for effective budgeting and financial analysis. Properly distinguishing these costs ensures that Your maintenance strategies are data-driven, enabling improved resource allocation and cost control. Misallocation can lead to distorted cost reporting, resulting in misguided decision-making and reduced operational efficiency.

Conclusion: Balancing Direct and Indirect Maintenance Costs

Balancing direct and indirect maintenance costs is essential for optimizing overall operational efficiency and budget allocation. Direct maintenance costs include labor, parts, and materials, while indirect costs cover downtime, lost productivity, and administrative expenses. Effective maintenance strategies prioritize minimizing indirect costs through preventive measures while controlling direct expenditures to achieve sustainable cost management.

Direct maintenance cost vs Indirect maintenance cost Infographic

libmatt.com

libmatt.com