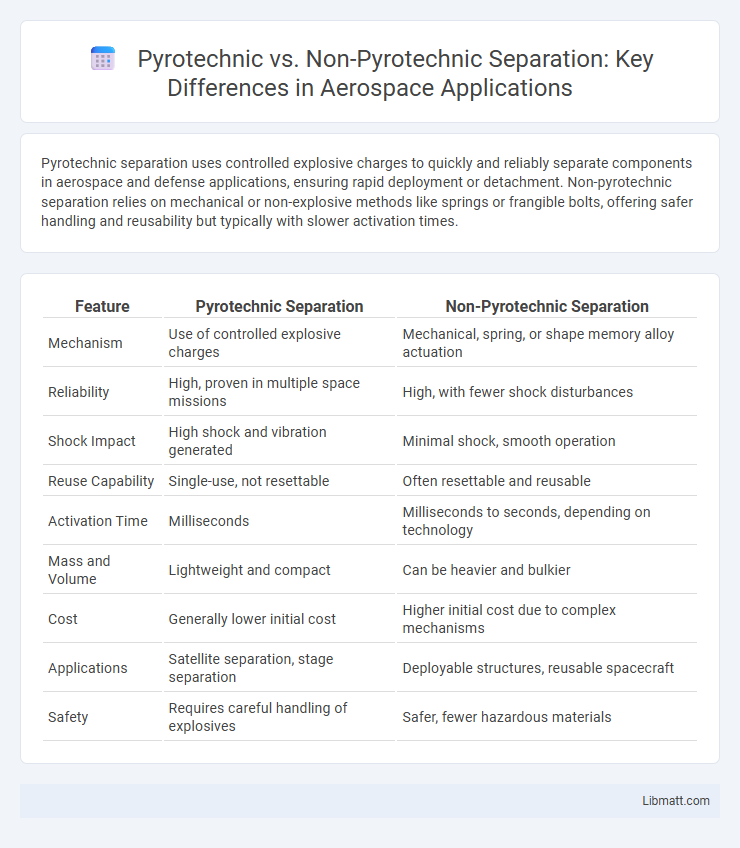

Pyrotechnic separation uses controlled explosive charges to quickly and reliably separate components in aerospace and defense applications, ensuring rapid deployment or detachment. Non-pyrotechnic separation relies on mechanical or non-explosive methods like springs or frangible bolts, offering safer handling and reusability but typically with slower activation times.

Table of Comparison

| Feature | Pyrotechnic Separation | Non-Pyrotechnic Separation |

|---|---|---|

| Mechanism | Use of controlled explosive charges | Mechanical, spring, or shape memory alloy actuation |

| Reliability | High, proven in multiple space missions | High, with fewer shock disturbances |

| Shock Impact | High shock and vibration generated | Minimal shock, smooth operation |

| Reuse Capability | Single-use, not resettable | Often resettable and reusable |

| Activation Time | Milliseconds | Milliseconds to seconds, depending on technology |

| Mass and Volume | Lightweight and compact | Can be heavier and bulkier |

| Cost | Generally lower initial cost | Higher initial cost due to complex mechanisms |

| Applications | Satellite separation, stage separation | Deployable structures, reusable spacecraft |

| Safety | Requires careful handling of explosives | Safer, fewer hazardous materials |

Introduction to Spacecraft Separation Mechanisms

Spacecraft separation mechanisms are critical for ensuring safe and reliable deployment of satellites and payloads during missions. Pyrotechnic separation uses controlled explosive devices to achieve rapid and precise detachment but can generate shock and debris that may affect sensitive components. Non-pyrotechnic separation employs mechanical or spring-based systems, offering smoother release with reduced vibration, which enhances the longevity and integrity of Your spacecraft's instruments.

Overview of Pyrotechnic Separation Systems

Pyrotechnic separation systems utilize controlled explosive charges to achieve rapid, reliable detachment of components in aerospace and defense applications, ensuring precise and immediate separation. These systems are favored for their high shock energy output and quick activation, which is critical in payload deployment or stage separation during rocket launches. In contrast, non-pyrotechnic separation methods rely on mechanical, thermal, or other non-explosive technologies, often offering reusability and reduced shock but typically at the expense of separation speed and reliability.

Overview of Non-Pyrotechnic Separation Systems

Non-pyrotechnic separation systems utilize mechanical, spring-based, or shape memory alloy mechanisms to achieve spacecraft component separation without explosive materials. These systems offer enhanced safety by eliminating shock and vibration associated with pyrotechnic devices, making them ideal for sensitive payloads and delicate instruments. Key advantages include improved reliability, reusability potential, and reduced contamination risks in space missions.

Key Differences Between Pyrotechnic and Non-Pyrotechnic Separation

Pyrotechnic separation uses controlled explosive charges to rapidly sever mechanical connections, ensuring high reliability and rapid deployment in aerospace and defense applications. Non-pyrotechnic separation employs mechanical, thermal, or shape-memory alloy mechanisms that offer reusability and reduced shock, suitable for sensitive payloads requiring minimal disturbance. Your choice depends on mission requirements for shock tolerance, reliability, and reusability in separation systems.

Advantages of Pyrotechnic Separation

Pyrotechnic separation offers rapid and reliable severing mechanisms essential for spacecraft and aerospace applications, providing high precision and minimal mechanical complexity compared to non-pyrotechnic methods. Its ability to deliver instantaneous force ensures effective deployment of components like solar panels or satellite stages, enhancing mission success rates. Your choice of pyrotechnic separation can improve system reliability through its proven track record in critical spacecraft separation events.

Advantages of Non-Pyrotechnic Separation

Non-pyrotechnic separation systems offer enhanced safety by eliminating explosive charges, reducing shock and vibration that can damage sensitive satellite components. They provide precise control over separation timing and force, ensuring reliability in delicate space missions. These systems also enable reusability and simpler ground handling procedures compared to pyrotechnic counterparts.

Common Applications for Each Separation Method

Pyrotechnic separation is commonly used in aerospace applications such as satellite deployment and rocket stage separation due to its rapid, reliable, and high-force release capabilities. Non-pyrotechnic separation methods, including mechanical or shape-memory alloy actuators, are prevalent in reusable spacecraft and sensitive instrumentation where precise, shock-free separation is critical. Both methods match specific mission requirements, with pyrotechnic favoring single-use, high-impact scenarios and non-pyrotechnic suited for controlled, repeatable operations.

Reliability and Safety Considerations

Pyrotechnic separation systems offer high reliability through rapid and predictable fracture mechanisms but introduce safety concerns due to explosive materials and shock loads on surrounding components. Non-pyrotechnic separation methods, such as shape memory alloys or mechanical actuators, enhance safety by eliminating explosive hazards while potentially providing more controlled and reversible separation processes. Evaluating the trade-offs between immediate reliability and long-term safety is critical in aerospace and defense applications where mission success and personnel protection are paramount.

Recent Innovations in Separation Technologies

Recent innovations in separation technologies have enhanced pyrotechnic separation methods by improving precision, reducing shock, and increasing reliability during satellite deployment or missile stage separation. Non-pyrotechnic separation technologies, such as shape memory alloy (SMA) actuators and clamp band systems, are gaining traction due to their reusability, lower vibration, and enhanced safety for sensitive payloads. Your choice between pyrotechnic and non-pyrotechnic systems depends on mission-specific requirements like timing accuracy, shock tolerance, and operational environment.

Future Trends in Spacecraft Separation Systems

Future trends in spacecraft separation systems emphasize increased reliability and reusability, with non-pyrotechnic separation mechanisms gaining traction for their precision and reduced shock impact on sensitive payloads. Pyrotechnic separation remains vital for its proven rapid activation and high-energy release, but innovations are leading toward hybrid systems that combine the strengths of both technologies. Your spacecraft's mission success can benefit from advancements in smart materials and electric actuators, which drive the evolution of safer, lighter, and more controllable separation systems.

pyrotechnic separation vs non-pyrotechnic separation Infographic

libmatt.com

libmatt.com