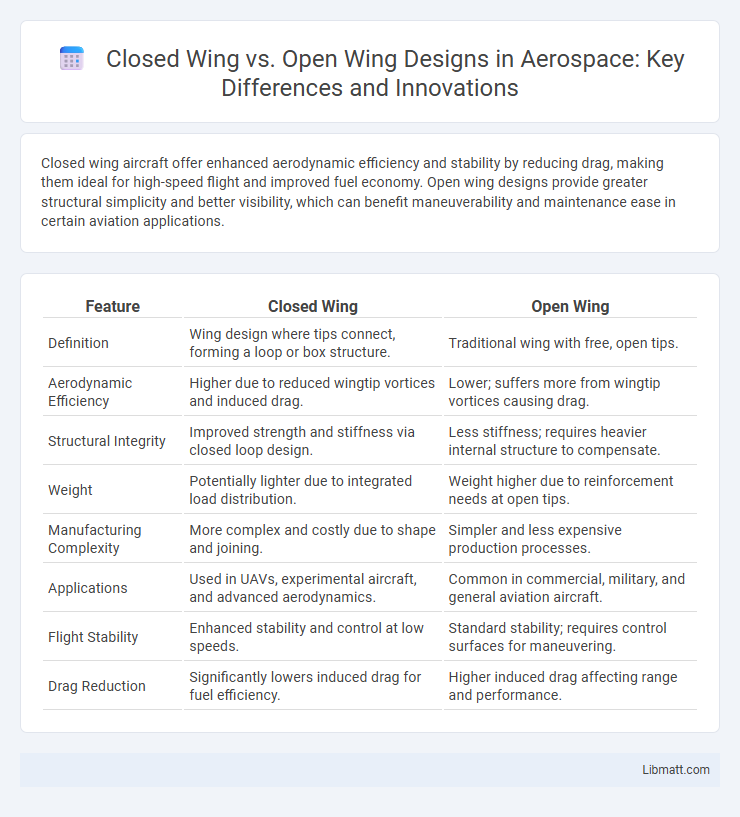

Closed wing aircraft offer enhanced aerodynamic efficiency and stability by reducing drag, making them ideal for high-speed flight and improved fuel economy. Open wing designs provide greater structural simplicity and better visibility, which can benefit maneuverability and maintenance ease in certain aviation applications.

Table of Comparison

| Feature | Closed Wing | Open Wing |

|---|---|---|

| Definition | Wing design where tips connect, forming a loop or box structure. | Traditional wing with free, open tips. |

| Aerodynamic Efficiency | Higher due to reduced wingtip vortices and induced drag. | Lower; suffers more from wingtip vortices causing drag. |

| Structural Integrity | Improved strength and stiffness via closed loop design. | Less stiffness; requires heavier internal structure to compensate. |

| Weight | Potentially lighter due to integrated load distribution. | Weight higher due to reinforcement needs at open tips. |

| Manufacturing Complexity | More complex and costly due to shape and joining. | Simpler and less expensive production processes. |

| Applications | Used in UAVs, experimental aircraft, and advanced aerodynamics. | Common in commercial, military, and general aviation aircraft. |

| Flight Stability | Enhanced stability and control at low speeds. | Standard stability; requires control surfaces for maneuvering. |

| Drag Reduction | Significantly lowers induced drag for fuel efficiency. | Higher induced drag affecting range and performance. |

Introduction to Closed Wing and Open Wing Designs

Closed wing and open wing designs represent two fundamental approaches in aerospace engineering, influencing aircraft performance and efficiency. Closed wing configurations feature a continuous loop or connected wingtips, enhancing structural rigidity and reducing induced drag, which can improve fuel efficiency and stability. Open wing designs, by contrast, have distinct, separate wings that allow for easier manufacturing and maintenance but typically experience higher aerodynamic drag compared to closed wing systems.

Historical Evolution of Wing Configurations

The historical evolution of wing configurations reflects significant advancements from open wing designs, prevalent in early aviation for simplicity and ease of construction, to closed wing configurations, which emerged to enhance aerodynamic efficiency and structural integrity. Closed wings, such as box wings and joined wings, have gained attention for reducing induced drag and improving lift-to-drag ratio compared to traditional open wings. Understanding these developments can help you appreciate how modern aircraft designs balance performance, fuel efficiency, and stability through innovative wing architecture.

Structural Differences Between Closed and Open Wings

Closed wings, also known as box wings, feature a continuous loop connecting the wing tips, which enhances structural rigidity and reduces wingtip vortices, improving aerodynamic efficiency. Open wings, or conventional wings, have separate tips without a connecting surface, resulting in simpler construction but higher induced drag due to stronger wingtip vortices. The closed wing design distributes aerodynamic loads more evenly across the structure, allowing for lighter materials and increased load-carrying capacity compared to the open wing configuration.

Aerodynamic Performance Comparison

Closed wing configurations exhibit enhanced aerodynamic performance due to reduced induced drag and improved lift-to-drag ratio compared to open wing designs. The continuous loop structure in closed wings minimizes wingtip vortices, leading to greater efficiency at various flight speeds. Open wings typically experience higher vortex formation and drag, limiting their effectiveness in fuel consumption and overall flight stability.

Efficiency and Fuel Consumption Analysis

Closed wing designs typically offer superior aerodynamic efficiency by reducing wingtip vortices and induced drag, resulting in lower fuel consumption during cruise flight. Open wing configurations often experience higher drag due to exposed wingtips, which can increase fuel burn and reduce overall operational efficiency. Aircraft with closed wing structures, such as joined wings or box wings, demonstrate improved lift-to-drag ratios, contributing to enhanced fuel economy and longer range capabilities.

Advantages of Closed Wing Aircraft

Closed wing aircraft offer enhanced structural efficiency, reducing wing bending moments and increasing overall strength with less material weight. This design improves aerodynamic performance by minimizing induced drag, resulting in better fuel efficiency and increased range. Additionally, the closed wing configuration provides greater stability and control, especially at low speeds and during high-angle-of-attack maneuvers.

Benefits and Challenges of Open Wing Designs

Open wing designs offer enhanced visibility and natural ventilation, promoting energy efficiency and user comfort in architectural spaces. These designs facilitate better airflow and natural lighting, reducing reliance on artificial climate control and lighting systems, which can lower operational costs. However, open wings may pose challenges such as increased exposure to weather elements and security concerns, requiring strategic planning and materials to mitigate these risks effectively.

Applications in Commercial and Military Aviation

Closed wing designs, such as joined wings and box wings, offer enhanced aerodynamic efficiency and structural strength, making them suitable for reducing drag and improving fuel efficiency in commercial aviation. Open wing configurations dominate traditional aircraft designs due to their simplicity, ease of maintenance, and proven versatility in both commercial airliners and military fighter jets. Military aviation often favors open wings for maneuverability and payload flexibility, while emerging closed wing concepts are explored to achieve stealth capabilities and longer endurance in unmanned aerial vehicles.

Emerging Technologies Shaping Wing Design

Emerging technologies like morphing materials and adaptive control systems are revolutionizing both closed wing and open wing designs by enhancing aerodynamic efficiency and structural integrity. Closed wings benefit from advanced composite materials that reduce weight while maintaining strength, enabling improved lift-to-drag ratios and fuel efficiency. Your aircraft's performance can greatly improve by integrating smart sensors and real-time data analytics, optimizing wing shape dynamically for various flight conditions.

Future Trends in Aircraft Wing Architecture

Closed wing designs are gaining attention in future aircraft wing architecture for their potential to reduce drag and improve structural efficiency, enhancing fuel economy and range. Open wing configurations remain prevalent due to their simplicity and ease of maintenance but face challenges in aerodynamic optimization and noise reduction. Your next aircraft model could benefit from integrating innovative closed wing structures to capitalize on advancements in sustainable aviation technology.

closed wing vs open wing Infographic

libmatt.com

libmatt.com