Rotating Detonation Engines (RDEs) generate continuous detonation waves around an annular combustion chamber, offering improved thermal efficiency and smoother thrust compared to Pulse Detonation Engines (PDEs), which rely on intermittent detonations in a linear or annular tube. Your choice depends on application requirements, as RDEs excel in steady propulsion while PDEs provide simpler design and potentially higher specific impulse in pulsed operation.

Table of Comparison

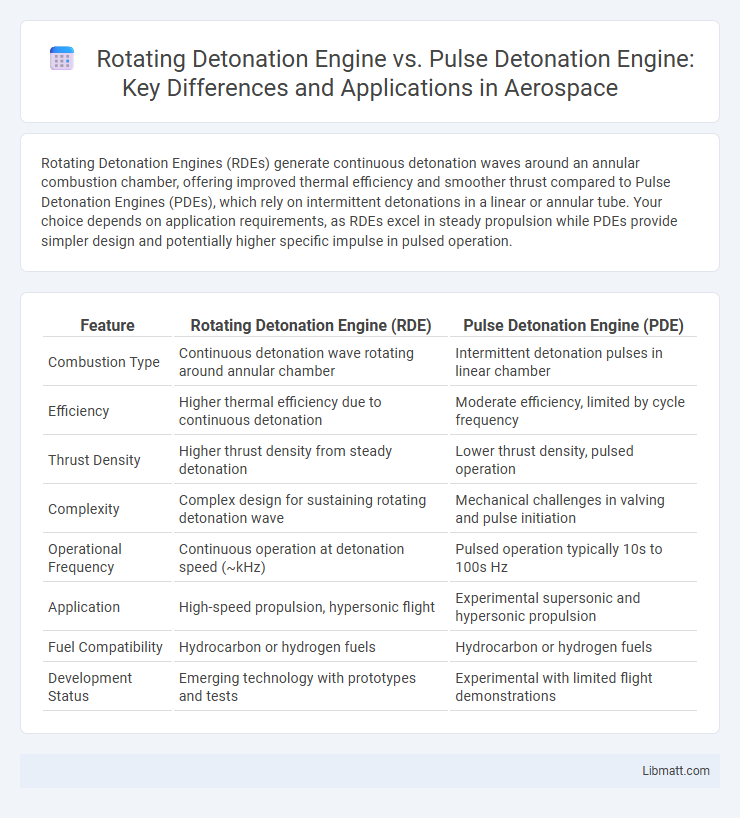

| Feature | Rotating Detonation Engine (RDE) | Pulse Detonation Engine (PDE) |

|---|---|---|

| Combustion Type | Continuous detonation wave rotating around annular chamber | Intermittent detonation pulses in linear chamber |

| Efficiency | Higher thermal efficiency due to continuous detonation | Moderate efficiency, limited by cycle frequency |

| Thrust Density | Higher thrust density from steady detonation | Lower thrust density, pulsed operation |

| Complexity | Complex design for sustaining rotating detonation wave | Mechanical challenges in valving and pulse initiation |

| Operational Frequency | Continuous operation at detonation speed (~kHz) | Pulsed operation typically 10s to 100s Hz |

| Application | High-speed propulsion, hypersonic flight | Experimental supersonic and hypersonic propulsion |

| Fuel Compatibility | Hydrocarbon or hydrogen fuels | Hydrocarbon or hydrogen fuels |

| Development Status | Emerging technology with prototypes and tests | Experimental with limited flight demonstrations |

Introduction to Detonation-Based Propulsion

Detonation-based propulsion harnesses shockwave-induced combustion for enhanced efficiency and performance in aerospace applications. Rotating Detonation Engines (RDEs) utilize continuous detonation waves circulating within an annular combustor, enabling steady thrust generation and improved thermodynamic efficiency. Pulse Detonation Engines (PDEs) operate via repetitive detonation pulses within a combustion tube, offering potential advantages in simplicity and fuel flexibility but facing challenges in cycle frequency and mechanical durability.

Core Principles of Rotating Detonation Engines

Rotating Detonation Engines (RDEs) operate on the principle of continuous detonation waves traveling circumferentially within an annular combustion chamber, creating a sustained pressure gain combustion process. This contrasts with Pulse Detonation Engines (PDEs) that rely on intermittent detonations producing discrete pressure pulses. Understanding the core mechanism of RDEs reveals potential advantages in increased thermodynamic efficiency and compact engine design, which can significantly enhance your propulsion system's performance.

Fundamentals of Pulse Detonation Engines

Pulse Detonation Engines (PDEs) operate on the principle of repetitive detonations within a combustion chamber, generating high-pressure shock waves that produce thrust more efficiently than traditional deflagration engines. PDEs use a cyclic process where fuel and oxidizer mixture detonates in pulses, leading to rapid energy release and improved thermodynamic efficiency. Understanding your PDE's detonation wave dynamics is crucial for optimizing combustion timing and maximizing propulsion performance compared to Rotating Detonation Engines.

Key Differences in Operating Mechanisms

Rotating Detonation Engines (RDEs) utilize continuous detonation waves traveling around an annular combustion chamber, enabling sustained supersonic combustion that improves efficiency and thrust. Pulse Detonation Engines (PDEs) operate through cyclic detonations in discrete combustion tubes, generating intermittent shock waves that produce thrust in pulses rather than a steady flow. Your choice between RDE and PDE depends on applications requiring continuous propulsion efficiency versus those accommodating pulsed thrust dynamics.

Comparative Performance and Efficiency

Rotating Detonation Engines (RDEs) demonstrate higher thermal efficiency and smoother combustion compared to Pulse Detonation Engines (PDEs), due to their continuous detonation waves minimizing pressure losses. PDEs operate through intermittent detonations leading to higher vibration and mechanical stress, which can reduce overall system durability and efficiency. Your choice between these propulsion systems depends on balancing the RDE's superior efficiency with PDE's simpler design and potential adaptability.

Structural Design and Engineering Challenges

Rotating Detonation Engines (RDEs) feature a continuous detonation wave around an annular combustion chamber, requiring advanced materials capable of withstanding extreme thermal and mechanical stresses due to rapid pressure fluctuations. Pulse Detonation Engines (PDEs) operate through intermittent detonations inside linear tubes, posing engineering challenges in managing cyclic thermal loads and ensuring rapid valve actuation for flame initiation and exhaust. Your choice between RDE and PDE influences structural design strategies, as RDE demands more robust cooling mechanisms and material resilience, while PDE requires precise synchronization of detonation pulses to maintain structural integrity and optimize performance.

Fuel Flexibility and Combustion Characteristics

Rotating Detonation Engines (RDEs) exhibit superior fuel flexibility compared to Pulse Detonation Engines (PDEs) due to their continuous detonation wave that efficiently sustains combustion across a variety of fuel-air mixtures, including hydrogen, jet fuels, and methane. RDEs achieve higher combustion stability and pressure gain by maintaining a quasi-steady detonation wave, whereas PDEs rely on intermittent, cyclic detonations that can introduce pressure losses and limit operational consistency. Fuel adaptability in RDEs enables optimized combustion characteristics such as increased thermal efficiency and reduced emissions, making them more versatile for advanced propulsion applications.

Applications in Aerospace and Propulsion

Rotating Detonation Engines (RDEs) offer continuous detonation combustion that improves fuel efficiency and thrust, making them suitable for future hypersonic aircraft and advanced rocket propulsion systems. Pulse Detonation Engines (PDEs) operate cyclically with discrete detonation pulses, providing advantages in simplicity and scalability for tactical missiles and experimental UAV propulsion. Both technologies aim to revolutionize aerospace propulsion by enhancing performance, reducing weight, and lowering emissions compared to conventional jet and rocket engines.

Advances in Research and Development

Recent advances in Rotating Detonation Engine (RDE) research highlight improvements in continuous detonation wave stability and fuel efficiency, enabling higher thrust-to-weight ratios compared to conventional propulsion systems. Pulse Detonation Engine (PDE) development focuses on enhancing cyclic detonation frequency and reducing mechanical complexity to achieve reliable pulse generation at higher operational frequencies. Both RDE and PDE technologies benefit from computational fluid dynamics (CFD) simulations and high-speed diagnostics, accelerating optimization of combustion chamber geometry and detonation wave interactions for practical aerospace applications.

Future Prospects and Industry Outlook

Rotating Detonation Engines (RDEs) promise higher fuel efficiency and improved thrust-to-weight ratios compared to Pulse Detonation Engines (PDEs), making them more suitable for next-generation aerospace propulsion systems. Industry forecasts highlight increased investment in RDE technology due to its potential for reduced emissions and operational costs in both military and commercial aviation sectors. Continued advancements in materials and combustion control are expected to accelerate RDE integration into hypersonic vehicles and sustainable aviation initiatives over the next decade.

Rotating Detonation Engine vs Pulse Detonation Engine Infographic

libmatt.com

libmatt.com