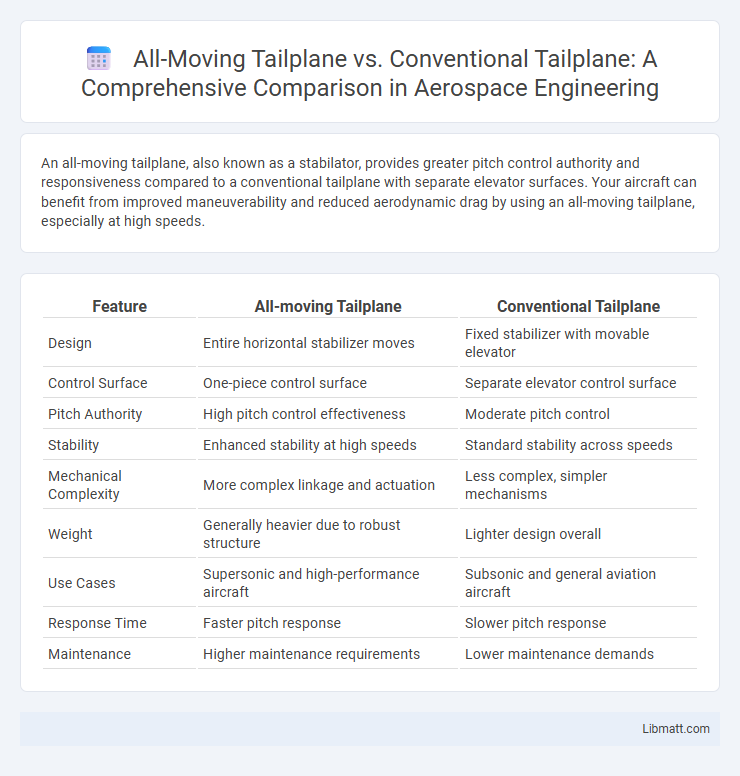

An all-moving tailplane, also known as a stabilator, provides greater pitch control authority and responsiveness compared to a conventional tailplane with separate elevator surfaces. Your aircraft can benefit from improved maneuverability and reduced aerodynamic drag by using an all-moving tailplane, especially at high speeds.

Table of Comparison

| Feature | All-moving Tailplane | Conventional Tailplane |

|---|---|---|

| Design | Entire horizontal stabilizer moves | Fixed stabilizer with movable elevator |

| Control Surface | One-piece control surface | Separate elevator control surface |

| Pitch Authority | High pitch control effectiveness | Moderate pitch control |

| Stability | Enhanced stability at high speeds | Standard stability across speeds |

| Mechanical Complexity | More complex linkage and actuation | Less complex, simpler mechanisms |

| Weight | Generally heavier due to robust structure | Lighter design overall |

| Use Cases | Supersonic and high-performance aircraft | Subsonic and general aviation aircraft |

| Response Time | Faster pitch response | Slower pitch response |

| Maintenance | Higher maintenance requirements | Lower maintenance demands |

Introduction to Aircraft Tailplane Designs

All-moving tailplanes offer enhanced control authority by adjusting the entire horizontal stabilizer surface, improving aircraft maneuverability and response, especially at high speeds. Conventional tailplanes utilize a fixed horizontal stabilizer with separate elevators, providing stable pitch control but with less responsiveness compared to all-moving designs. Your choice between these designs impacts aircraft performance, handling characteristics, and complexity in the control system.

What is a Conventional Tailplane?

A Conventional Tailplane consists of a fixed horizontal stabilizer and a movable elevator hinged to its trailing edge, providing pitch control and stability to the aircraft. It maintains aircraft balance by generating aerodynamic forces that counteract pitching moments during flight. This design is widely used in general aviation and commercial aircraft due to its simplicity and reliable control characteristics.

Understanding the All-Moving Tailplane

The all-moving tailplane, also known as a stabilator, integrates the entire horizontal surface to pivot, providing greater pitch control and improved aerodynamic efficiency compared to the fixed horizontal stabilizer with a hinged elevator found in conventional tailplanes. This design enhances aircraft responsiveness and stability, especially at high speeds and varying flight conditions. Understanding the all-moving tailplane helps you appreciate its role in modern aerospace engineering and its impact on flight performance and control precision.

Key Aerodynamic Differences

All-moving tailplanes, also known as stabilators, provide greater pitch control authority and reduced aerodynamic drag compared to conventional tailplanes, which consist of a fixed horizontal stabilizer with a separate hinged elevator. The all-moving tailplane adjusts its entire surface angle, resulting in more responsive control and improved efficiency at various airspeeds, especially at transonic and supersonic regimes. Conversely, conventional tailplanes offer simpler mechanical structures but can experience control surface hinge moments and less precise pitch control due to elevator deflection alone.

Control Authority and Maneuverability

All-moving tailplanes provide greater control authority by allowing the entire horizontal stabilizer to pivot, enabling more precise and responsive pitch adjustments compared to conventional tailplanes, which rely on fixed horizontal stabilizers with separate elevators. This increased control surface movement improves maneuverability, especially at high speeds and during rapid attitude changes. Conventional tailplanes offer stability and predictable handling but may present limitations in responsiveness and control effectiveness in extreme flight conditions.

Stability and Handling Characteristics

All-moving tailplanes, also known as stabilators, provide enhanced pitch control and improved handling at high speeds due to their ability to change the entire horizontal surface angle. Conventional tailplanes, with fixed stabilizers and separate elevators, offer greater inherent stability but may experience control surface effectiveness reduction at transonic speeds. The all-moving tailplane's design reduces aerodynamic flutter and increases responsiveness, making it preferable for supersonic and high-performance aircraft, while conventional tailplanes are favored for their straightforward stability and ease of control in general aviation.

Applications in Modern Aircraft

All-moving tailplanes, also known as stabilators, provide enhanced pitch control and are widely used in high-performance military jets and supersonic aircraft due to their responsiveness at various speeds. Conventional tailplanes, featuring fixed horizontal stabilizers with separate elevators, remain common in commercial airliners and general aviation aircraft because of their stability and ease of maintenance. Your choice between the two depends on the aircraft's speed regime and maneuverability requirements, with all-moving tailplanes excelling in agility and conventional designs offering proven reliability.

Maintenance and Structural Considerations

All-moving tailplanes require fewer moving parts such as hinges and control rods, reducing maintenance frequency and complexity compared to conventional tailplanes that have separate fixed stabilizers and elevators prone to wear and corrosion. Structurally, all-moving tailplanes experience higher aerodynamic loads as the entire surface pivots for pitch control, necessitating stronger materials and robust attachment mechanisms to prevent fatigue failure. Conventional tailplanes distribute stresses between the fixed stabilizer and smaller moving elevators, allowing for lighter structural design but increased inspection points to monitor hinge integrity and control linkages.

Advantages and Disadvantages Comparison

All-moving tailplanes, also known as stabilators, provide greater control authority and responsiveness at various speeds, making them ideal for high-performance and supersonic aircraft; they reduce aerodynamic flutter risk due to their single-piece design and simplify control mechanisms by eliminating separate elevator surfaces. Conventional tailplanes offer more straightforward mechanical complexity, ease of maintenance, and enhanced pitch stability suited for general aviation and slower aircraft, but suffer from reduced control effectiveness at high speeds and increased susceptibility to aerodynamic buffet. The trade-offs between all-moving and conventional tailplanes revolve around performance requirements, with all-moving tailplanes favoring maneuverability and aerodynamic efficiency while conventional tailplanes prioritize stability and structural simplicity.

Choosing the Right Tailplane Configuration

Selecting the right tailplane configuration depends on the aircraft's performance requirements and control characteristics, with all-moving tailplanes offering greater pitch control authority and reduced aerodynamic drag compared to conventional fixed tailplanes with elevators. All-moving tailplanes, often found in supersonic and high-performance aircraft, improve stability and responsiveness at varying speeds, while conventional tailplanes provide simpler design, easier maintenance, and cost-effectiveness for general aviation and slower aircraft. Engineers must balance factors like maneuverability, weight, complexity, and mission profile to determine the optimal tailplane type for specific flight conditions.

All-moving Tailplane vs Conventional Tailplane Infographic

libmatt.com

libmatt.com