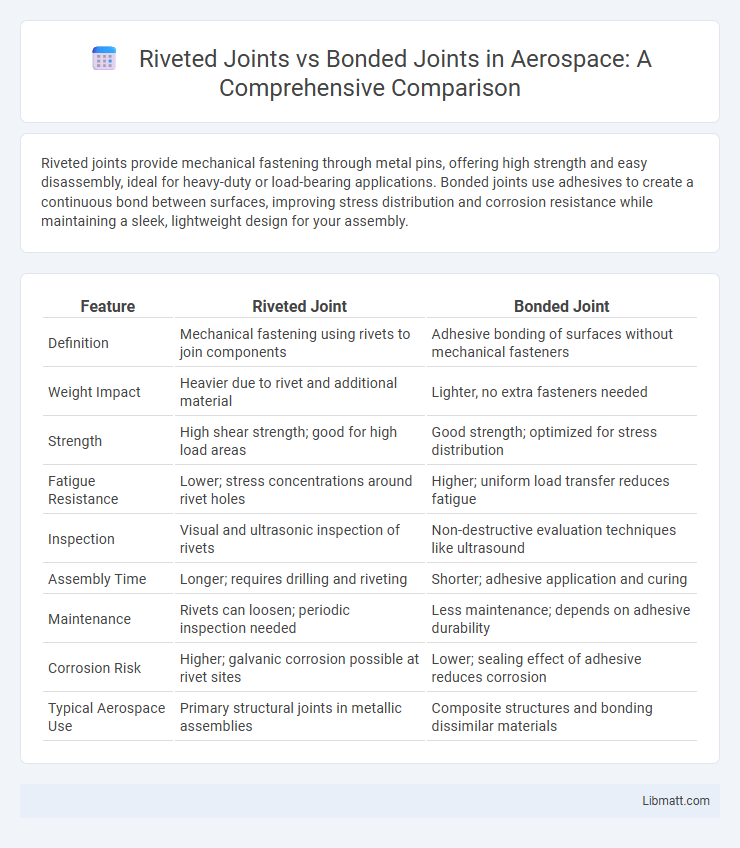

Riveted joints provide mechanical fastening through metal pins, offering high strength and easy disassembly, ideal for heavy-duty or load-bearing applications. Bonded joints use adhesives to create a continuous bond between surfaces, improving stress distribution and corrosion resistance while maintaining a sleek, lightweight design for your assembly.

Table of Comparison

| Feature | Riveted Joint | Bonded Joint |

|---|---|---|

| Definition | Mechanical fastening using rivets to join components | Adhesive bonding of surfaces without mechanical fasteners |

| Weight Impact | Heavier due to rivet and additional material | Lighter, no extra fasteners needed |

| Strength | High shear strength; good for high load areas | Good strength; optimized for stress distribution |

| Fatigue Resistance | Lower; stress concentrations around rivet holes | Higher; uniform load transfer reduces fatigue |

| Inspection | Visual and ultrasonic inspection of rivets | Non-destructive evaluation techniques like ultrasound |

| Assembly Time | Longer; requires drilling and riveting | Shorter; adhesive application and curing |

| Maintenance | Rivets can loosen; periodic inspection needed | Less maintenance; depends on adhesive durability |

| Corrosion Risk | Higher; galvanic corrosion possible at rivet sites | Lower; sealing effect of adhesive reduces corrosion |

| Typical Aerospace Use | Primary structural joints in metallic assemblies | Composite structures and bonding dissimilar materials |

Introduction to Riveted and Bonded Joints

Riveted joints use metal pins or bolts to mechanically fasten components, providing high strength and reliability in structural applications, especially where disassembly might be required. Bonded joints rely on adhesives to create a uniform load transfer between surfaces, offering improved stress distribution and resistance to vibration without adding extra weight. Your choice between riveted and bonded joints depends on factors such as material compatibility, load conditions, and the need for sealing or electrical insulation.

Basic Principles of Riveted Joints

Riveted joints rely on mechanical fastening where metal pins, or rivets, are inserted through aligned holes in components and deformed to hold materials securely together, providing strong shear resistance and durability. This method ensures reliable load distribution and is widely used in structural applications such as bridges and aircraft due to its ability to withstand dynamic stresses. Your choice of riveted joints can enhance mechanical stability, especially in environments subject to vibration or cyclic loading.

Basic Principles of Bonded Joints

Bonded joints rely on adhesive materials to create a strong molecular bond between surfaces, distributing stress evenly and providing resistance to shear and tensile forces. This type of joint eliminates the need for mechanical fasteners, reducing stress concentrations and weight while enhancing corrosion resistance. Proper surface preparation and adhesive selection are critical to achieving optimal bond strength and durability in various applications.

Material Compatibility in Riveted vs Bonded Joints

Riveted joints accommodate a wide range of materials, including metals with varying thicknesses and composites, due to their mechanical fastening nature. Bonded joints require compatible adhesives and surface treatments tailored to substrate materials, often limiting use to substrates with chemical affinity for the adhesive. Your choice depends on the materials involved and the required strength and durability, with riveted joints offering greater versatility in material compatibility compared to bonded joints.

Strength and Load-Bearing Capabilities

Riveted joints provide high strength and excellent shear load resistance due to metal fasteners securely holding components together, making them ideal for heavy structural applications. Bonded joints distribute stress uniformly across the adhesive layer, offering superior fatigue resistance and strong tensile load-bearing capabilities, particularly in lightweight materials. Your choice depends on whether you prioritize mechanical fastening reliability or seamless load distribution for enhanced joint performance.

Durability and Maintenance Considerations

Riveted joints offer high durability and can withstand dynamic loads, but require regular inspection and maintenance to prevent loosening or corrosion of the rivets. Bonded joints provide a seamless finish with excellent resistance to fatigue and vibration, reducing maintenance needs, though their durability can be compromised by environmental factors like moisture and temperature changes. Your choice depends on the specific application demands for long-term performance and the expected maintenance schedule.

Applications in Various Industries

Riveted joints are extensively used in aerospace and automotive industries due to their high strength, durability, and ability to withstand dynamic loads and vibrations in structural assemblies. Bonded joints find widespread applications in electronics, aerospace, and automotive sectors, particularly for joining dissimilar materials and providing uniform stress distribution without adding extra weight. Both joint types are crucial in shipbuilding and construction, where riveted joints ensure mechanical stability and bonded joints enhance corrosion resistance and fatigue performance.

Cost and Manufacturing Efficiency

Riveted joints generally have higher manufacturing costs due to the labor-intensive process and requirement for specialized tools, while bonded joints offer cost efficiency by enabling faster assembly and reduced material handling. Bonded joints eliminate the need for hole drilling and fastener inventory, significantly streamlining production and lowering overall expenses. When optimizing for cost and manufacturing efficiency, your choice should align with the specific application needs and production volume.

Failure Modes and Reliability

Riveted joints commonly experience failure modes such as shear failure of the rivets, bearing failure of the connected plates, and fatigue cracking around rivet holes, affecting their overall reliability in cyclic loading conditions. Bonded joints, however, are primarily susceptible to adhesive failure, including cohesive failure within the adhesive layer and interfacial delamination, which can compromise the joint's integrity under environmental degradation or peel stresses. The reliability of riveted joints tends to be higher in applications requiring disassembly and inspection, while bonded joints offer superior stress distribution and corrosion resistance but may require rigorous quality control to prevent premature failure.

Choosing the Right Joint for Your Application

Selecting between a riveted joint and a bonded joint depends on factors such as load type, material compatibility, and environmental conditions. Riveted joints provide high mechanical strength and durability in dynamic or high-stress applications, while bonded joints offer superior sealing and resistance to corrosion, ideal for lightweight or fatigue-sensitive structures. For your application, consider the balance between mechanical demands and exposure to elements to determine the optimal joint type.

riveted joint vs bonded joint Infographic

libmatt.com

libmatt.com