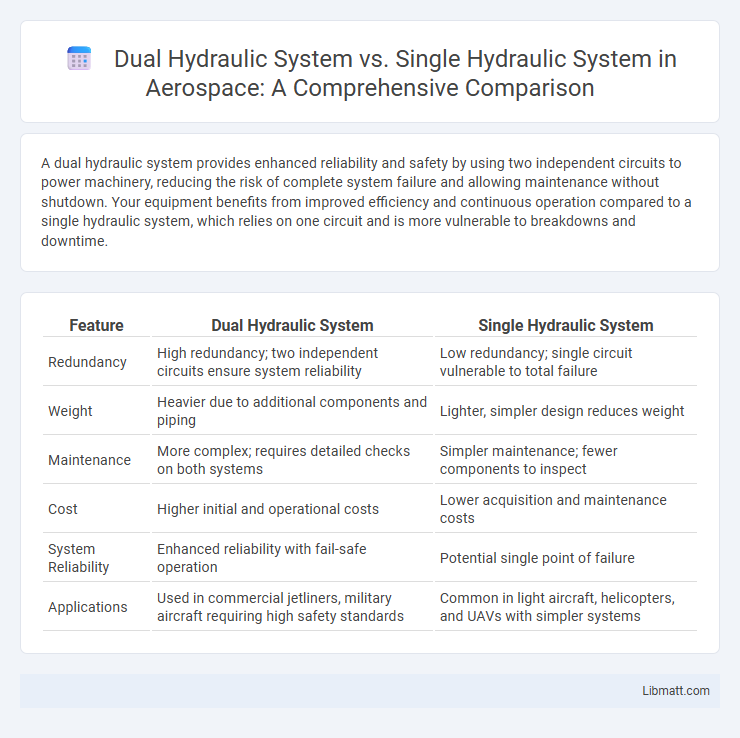

A dual hydraulic system provides enhanced reliability and safety by using two independent circuits to power machinery, reducing the risk of complete system failure and allowing maintenance without shutdown. Your equipment benefits from improved efficiency and continuous operation compared to a single hydraulic system, which relies on one circuit and is more vulnerable to breakdowns and downtime.

Table of Comparison

| Feature | Dual Hydraulic System | Single Hydraulic System |

|---|---|---|

| Redundancy | High redundancy; two independent circuits ensure system reliability | Low redundancy; single circuit vulnerable to total failure |

| Weight | Heavier due to additional components and piping | Lighter, simpler design reduces weight |

| Maintenance | More complex; requires detailed checks on both systems | Simpler maintenance; fewer components to inspect |

| Cost | Higher initial and operational costs | Lower acquisition and maintenance costs |

| System Reliability | Enhanced reliability with fail-safe operation | Potential single point of failure |

| Applications | Used in commercial jetliners, military aircraft requiring high safety standards | Common in light aircraft, helicopters, and UAVs with simpler systems |

Introduction to Hydraulic Systems

Hydraulic systems use fluid pressure to perform work, essential in various machinery and industrial applications. A single hydraulic system operates with one pump and circuit, providing focused control but limited redundancy. Dual hydraulic systems incorporate two independent circuits, enhancing reliability, safety, and operational efficiency by allowing one system to take over if the other fails.

Overview of Single Hydraulic System

A single hydraulic system uses one basic circuit to control hydraulic power, offering simplicity and lower initial cost ideal for smaller or less complex machinery. This system relies on one pump, one set of valves, and a single fluid reservoir to perform all hydraulic functions, providing straightforward maintenance and operation. Your choice of a single hydraulic system suits applications where basic performance, reliability, and cost-efficiency are top priorities without the need for redundancy or enhanced safety features.

Overview of Dual Hydraulic System

A Dual Hydraulic System consists of two independent hydraulic circuits that provide enhanced safety and redundancy by ensuring continuous operation if one circuit fails. This system optimizes power distribution and reliability in heavy machinery, aircraft, and industrial equipment, reducing downtime and maintenance costs. Its design supports higher operational efficiency and increased performance compared to Single Hydraulic Systems, which rely on a single circuit vulnerable to failure.

Key Components Comparison

The Dual Hydraulic System features two independent pumps, reservoirs, and control valves, enhancing redundancy and reliability, while the Single Hydraulic System contains only one set of these components, increasing vulnerability to failure. Key components like accumulators and actuators in dual systems provide more efficient pressure management and operational safety compared to the single system's limited redundancy. Your choice between these systems should consider the critical importance of system uptime and maintenance complexity in your application.

Performance Efficiency Analysis

Dual hydraulic systems offer enhanced performance efficiency by providing separate, dedicated circuits for different functions, reducing load on each pump and improving overall responsiveness. Single hydraulic systems, while simpler and cost-effective, may experience pressure drops and slower reaction times during simultaneous operations, limiting efficiency in high-demand applications. Your choice between dual and single hydraulic systems should consider the specific performance requirements and operational complexity of your equipment.

Reliability and Safety Considerations

Dual hydraulic systems enhance reliability and safety by providing redundancy, ensuring continuous operation if one circuit fails, which is critical in aviation and heavy machinery. Single hydraulic systems, while simpler and lighter, pose higher risks of total system failure and reduced operational safety due to the absence of backup circuits. Safety protocols in dual systems include automatic isolation of faulty circuits, minimizing hydraulic fluid loss and maintaining control under emergency conditions.

Maintenance Requirements and Costs

Dual hydraulic systems typically require more complex maintenance due to the presence of two separate circuits, increasing inspection, fluid changes, and potential leak points, which can lead to higher overall maintenance costs. Single hydraulic systems feature simpler designs, resulting in fewer components to service and lower routine maintenance expenses, making them more cost-effective for your budget. Choosing between the two depends on balancing the need for redundancy and power efficiency against maintenance complexity and operational costs.

Application Suitability and Versatility

Dual hydraulic systems provide enhanced application suitability by delivering independent control to two separate hydraulic circuits, making them ideal for complex machinery requiring simultaneous operations such as excavators and agricultural equipment. Single hydraulic systems offer simplicity and cost-effectiveness, fitting applications with straightforward functions like small loaders or lawn tractors. Your choice depends on the need for versatility and multi-functionality versus budget and maintenance considerations in your specific machinery use case.

Advantages and Disadvantages Summary

A Dual Hydraulic System offers enhanced reliability and safety by providing two independent hydraulic circuits, reducing the risk of complete system failure. You benefit from improved performance and redundancy but face higher initial costs and increased maintenance complexity compared to a Single Hydraulic System. Single systems are simpler, more cost-effective, and easier to maintain, though they lack backup capabilities, potentially leading to operational downtime if a fault occurs.

How to Choose the Right Hydraulic System

Choosing the right hydraulic system depends on your specific application needs, including pressure requirements, operational efficiency, and system complexity. Dual hydraulic systems offer enhanced redundancy and increased power capacity, making them ideal for heavy-duty or critical operations, while single hydraulic systems provide simplicity and cost-effectiveness for lighter tasks. Assess your machine's workload, maintenance capabilities, and budget to determine if a dual or single hydraulic system best supports your performance and reliability goals.

Dual Hydraulic System vs Single Hydraulic System Infographic

libmatt.com

libmatt.com