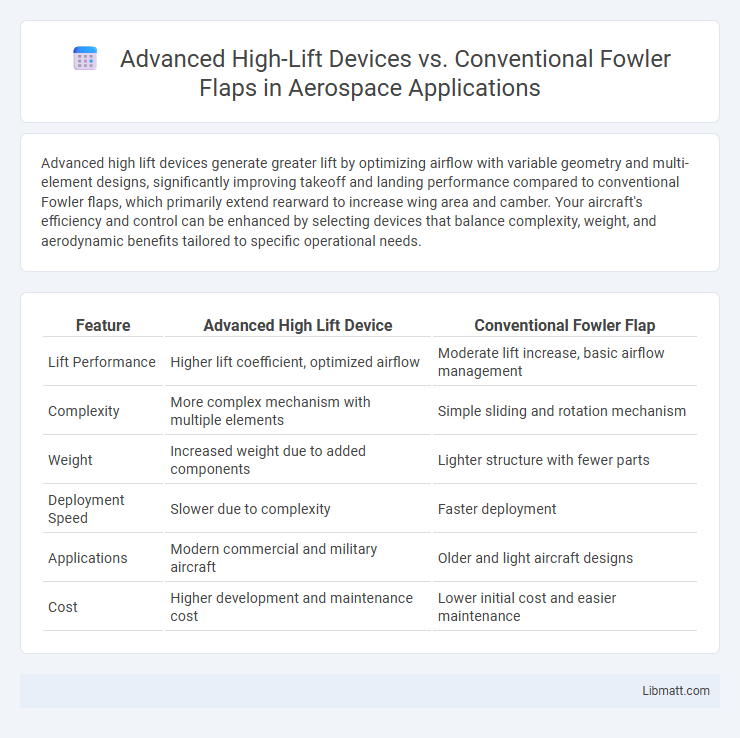

Advanced high lift devices generate greater lift by optimizing airflow with variable geometry and multi-element designs, significantly improving takeoff and landing performance compared to conventional Fowler flaps, which primarily extend rearward to increase wing area and camber. Your aircraft's efficiency and control can be enhanced by selecting devices that balance complexity, weight, and aerodynamic benefits tailored to specific operational needs.

Table of Comparison

| Feature | Advanced High Lift Device | Conventional Fowler Flap |

|---|---|---|

| Lift Performance | Higher lift coefficient, optimized airflow | Moderate lift increase, basic airflow management |

| Complexity | More complex mechanism with multiple elements | Simple sliding and rotation mechanism |

| Weight | Increased weight due to added components | Lighter structure with fewer parts |

| Deployment Speed | Slower due to complexity | Faster deployment |

| Applications | Modern commercial and military aircraft | Older and light aircraft designs |

| Cost | Higher development and maintenance cost | Lower initial cost and easier maintenance |

Introduction to High Lift Devices

Advanced high lift devices enhance aircraft performance by significantly increasing lift during takeoff and landing phases, utilizing complex mechanisms such as multi-slotted flaps, leading-edge slats, and Krueger flaps. Conventional Fowler flaps, a traditional high lift device, extend rearward and downward to increase wing area and camber, thereby improving lift but with simpler mechanical design and less incremental lift compared to advanced systems. The integration of advanced high lift devices enables improved aerodynamic efficiency, reduced approach speeds, and shorter runway requirements, key factors for modern commercial and military aircraft operations.

Overview of Conventional Fowler Flaps

Conventional Fowler flaps are high-lift devices mounted on the trailing edge of aircraft wings, designed to increase wing area and camber for enhanced lift during takeoff and landing. These flaps slide rearward and then deflect downward, improving lift coefficient significantly compared to plain flaps. Commonly used in commercial and general aviation, Fowler flaps optimize low-speed performance by reducing stall speed and improving short-field capabilities.

Evolution of Advanced High Lift Devices

Advanced high lift devices have evolved significantly from conventional Fowler flaps by incorporating multi-element systems such as slats, Krueger flaps, and trailing edge flaps to enhance lift and delay stall at low speeds. Modern designs use advanced materials and aerodynamic optimization to increase lift coefficients while minimizing drag and structural complexity. These innovations enable improved aircraft performance during takeoff and landing phases compared to the simpler, single-element Fowler flap systems.

Aerodynamic Principles: Fowler Flaps vs Advanced Devices

Fowler flaps increase lift by extending rearward and downward, enlarging the wing area and camber to enhance lift during takeoff and landing phases. Advanced high lift devices utilize multi-element configurations and adaptive morphing surfaces to optimize airflow, reduce drag, and improve lift-to-drag ratios more efficiently than conventional Fowler flaps. These devices employ advanced aerodynamic principles such as boundary layer control and vortex generation to achieve superior performance in various flight conditions.

Performance Impact: Lift, Drag, and Efficiency

Advanced high lift devices, such as multi-slot slats and Krueger flaps, significantly enhance maximum lift coefficients compared to conventional Fowler flaps by delaying flow separation at higher angles of attack. While conventional Fowler flaps increase wing area and camber, improving lift with a moderate drag penalty, advanced devices optimize airflow to reduce drag increments, thus maintaining better lift-to-drag ratios and overall aerodynamic efficiency. The improved lift-to-drag performance of advanced high lift systems contributes to lower stall speeds and enhanced aircraft performance during takeoff and landing phases.

Structural Complexity and Weight Considerations

Advanced high lift devices incorporate multiple movable surfaces and complex hinge mechanisms that increase structural complexity and overall aircraft weight compared to conventional Fowler flaps. Conventional Fowler flaps use simpler track and roller systems, resulting in lower weight penalties and easier maintenance. The trade-off between enhanced lift performance and added structural weight is a key factor in high lift system selection for commercial and military aircraft.

Integration with Modern Aircraft Systems

Advanced high lift devices offer superior integration with modern aircraft systems by utilizing automated control and adaptive materials, enhancing aerodynamic efficiency and reducing pilot workload. Conventional Fowler flaps rely on mechanical linkages and simpler actuation methods, limiting their responsiveness and integration with digital flight control systems. Your aircraft benefits from advanced systems that provide optimized lift and improved fuel efficiency through seamless integration with fly-by-wire technology and real-time performance monitoring.

Operational Benefits and Limitations

Advanced high lift devices provide enhanced lift coefficients and improved aerodynamic efficiency compared to conventional Fowler flaps, allowing shorter takeoff and landing distances. These devices typically offer better control over lift distribution and delay stall onset, improving aircraft performance during critical flight phases. Your choice may be influenced by factors such as mechanical complexity, maintenance requirements, and weight penalties associated with advanced systems versus the simplicity and reliability of conventional Fowler flaps.

Maintenance and Reliability Comparisons

Advanced high lift devices typically feature more complex mechanisms than conventional Fowler flaps, requiring specialized maintenance to ensure optimal operation and reliability. Conventional Fowler flaps have a simpler design, which often translates to easier inspection and lower maintenance costs. Your choice between these systems should consider the trade-off between enhanced aerodynamic performance and the increased maintenance demands of advanced high lift devices.

Future Trends in High Lift Device Technologies

Future trends in high lift device technologies emphasize the integration of morphing surfaces and adaptive materials to enhance aerodynamic efficiency beyond conventional Fowler flaps. Advanced high lift devices employ smart actuators and lightweight composites to provide improved lift-to-drag ratios, fuel savings, and noise reduction during critical flight phases. Your aircraft's performance and environmental footprint can benefit significantly as these innovative technologies evolve toward greater responsiveness and seamless aerodynamic adaptation.

Advanced high lift device vs Conventional Fowler flap Infographic

libmatt.com

libmatt.com