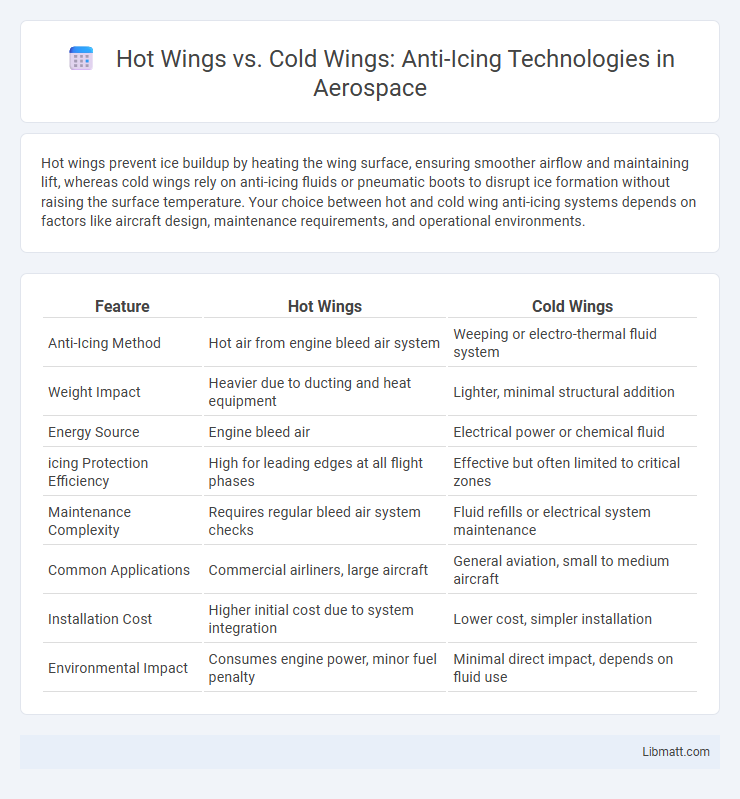

Hot wings prevent ice buildup by heating the wing surface, ensuring smoother airflow and maintaining lift, whereas cold wings rely on anti-icing fluids or pneumatic boots to disrupt ice formation without raising the surface temperature. Your choice between hot and cold wing anti-icing systems depends on factors like aircraft design, maintenance requirements, and operational environments.

Table of Comparison

| Feature | Hot Wings | Cold Wings |

|---|---|---|

| Anti-Icing Method | Hot air from engine bleed air system | Weeping or electro-thermal fluid system |

| Weight Impact | Heavier due to ducting and heat equipment | Lighter, minimal structural addition |

| Energy Source | Engine bleed air | Electrical power or chemical fluid |

| icing Protection Efficiency | High for leading edges at all flight phases | Effective but often limited to critical zones |

| Maintenance Complexity | Requires regular bleed air system checks | Fluid refills or electrical system maintenance |

| Common Applications | Commercial airliners, large aircraft | General aviation, small to medium aircraft |

| Installation Cost | Higher initial cost due to system integration | Lower cost, simpler installation |

| Environmental Impact | Consumes engine power, minor fuel penalty | Minimal direct impact, depends on fluid use |

Introduction to Hot Wings and Cold Wings Anti-Icing

Hot wings and cold wings represent two primary methods of aircraft anti-icing, crucial for maintaining flight safety in icy conditions. Hot wings utilize heated air from the engine to prevent ice buildup on the leading edges, ensuring aerodynamic efficiency and preventing control surface impairment. Cold wings rely on chemical de-icing fluids or mechanical systems to remove ice after accumulation, often employed during preflight or ground operations to maintain wing performance.

The Science Behind Aircraft Icing

Aircraft icing occurs when supercooled water droplets freeze upon contact with the airplane's surfaces, creating hazardous conditions that impact lift and control. Hot wings utilize bleed air from engines to maintain wing surface temperatures above freezing, preventing ice formation by melting or evaporating ice crystals. Cold wings rely on pneumatic boots or electro-thermal systems to break or remove accumulated ice after it forms, focusing on ice detection and mechanical removal rather than prevention.

Hot Wings Explained: Thermal De-icing Systems

Hot wings utilize thermal de-icing systems that apply heat directly to the aircraft's leading edges, preventing ice buildup during flight. These systems often use hot air bled from the engines to warm the wing surfaces, ensuring smooth airflow and maintaining aerodynamic efficiency. Thermal de-icing is favored for its reliability and continuous protection against ice formation in severe weather conditions.

Cold Wings Defined: Chemical and Pneumatic Anti-Icing

Cold wings refer to aircraft surfaces treated with chemical and pneumatic anti-icing systems to prevent ice accumulation during flight in freezing conditions. Chemical anti-icing uses fluids like glycol-based solutions sprayed on wings to inhibit ice formation, while pneumatic systems employ inflatable boots that mechanically break ice layers off the wing surface. Understanding the differences between these technologies helps you ensure optimal wing performance and flight safety in icy weather.

Key Differences Between Hot and Cold Wings

Hot wings utilize heated air or fluids to prevent ice accumulation during flight, ensuring consistent aerodynamic performance and safety in freezing conditions. Cold wings rely on chemical anti-icing fluids applied to the wing surface, which create a protective layer to inhibit ice formation but require careful monitoring and replenishment. Understanding these key differences helps you assess the maintenance, efficiency, and operational costs associated with each anti-icing system.

Performance Impact: Efficiency and Safety

Hot wings in anti-icing systems improve aircraft performance by efficiently preventing ice accumulation through heated airflow, ensuring better aerodynamic stability and reduced drag. Cold wings, relying on chemical anti-icing fluids, provide temporary protection but may lead to reduced efficiency and pose a higher risk during extended flights or severe weather conditions. Your choice of hot wings enhances safety margins and maintains optimal efficiency across varying atmospheric conditions.

Maintenance Requirements and Costs

Hot wings use heated air or fluid to prevent ice buildup, requiring more complex systems and higher initial installation costs but lower maintenance since they avoid mechanical parts prone to wear. Cold wings rely on chemical anti-icing fluids or pneumatic boots, leading to frequent service intervals and recurring expenses for fluid replenishment or boot repairs. Your choice impacts long-term operational costs, with hot wings often favored for cost efficiency in high-usage scenarios.

Suitability for Different Aircraft Types

Hot wings, which use heated air or electrical heating elements, are highly suitable for large commercial aircraft with complex systems capable of supporting these technologies efficiently. Cold wings, relying on kinetic ice protection with anti-icing fluids or coatings, are often used in smaller aircraft and general aviation where weight and power constraints limit the feasibility of hot wing systems. Your aircraft type and operational environment predominantly determine the most effective anti-icing method to ensure safe and efficient flight performance.

Environmental Considerations and Innovations

Hot wings utilize heated air or fluids to prevent ice accumulation, reducing chemical de-icer usage and minimizing environmental impact from toxic runoff. Cold wings employ mechanical ice removal and advanced anti-icing coatings that decrease reliance on harmful glycol-based substances, promoting eco-friendliness. Innovations in nanotechnology and bio-based de-icers are enhancing the effectiveness of both systems while addressing ecological sustainability concerns.

Future Trends in Aircraft Anti-Icing Technologies

Emerging trends in aircraft anti-icing technologies emphasize the shift from traditional hot wings systems to innovative cold wings solutions that reduce energy consumption and improve environmental sustainability. Advanced electro-thermal composites and ice-phobic coatings are revolutionizing deicing efficiency, offering lightweight alternatives that enhance performance and reduce maintenance costs. Your aircraft's safety and fuel efficiency can greatly benefit from integrating these next-generation anti-icing technologies, which align with the aviation industry's push for greener and smarter operations.

Hot Wings vs Cold Wings (anti-icing) Infographic

libmatt.com

libmatt.com