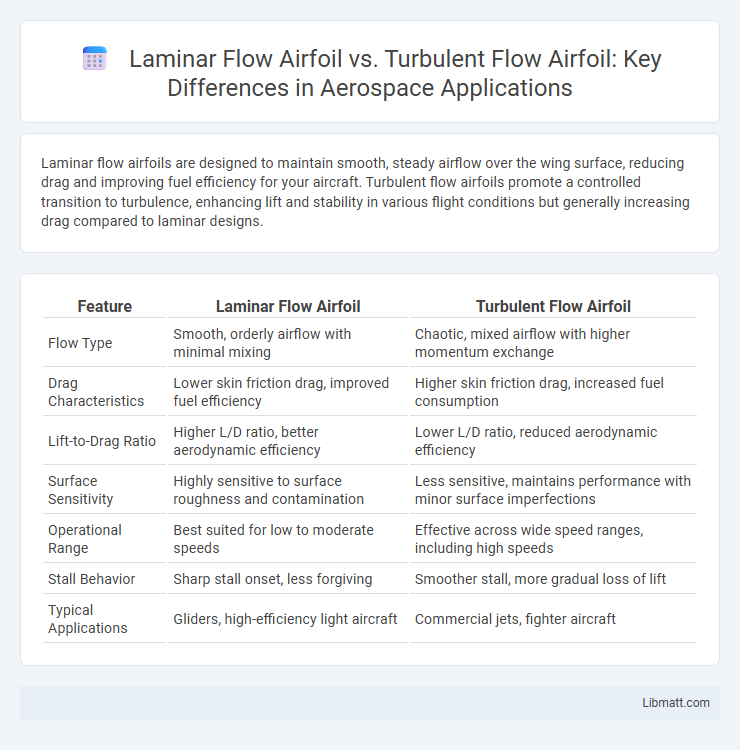

Laminar flow airfoils are designed to maintain smooth, steady airflow over the wing surface, reducing drag and improving fuel efficiency for your aircraft. Turbulent flow airfoils promote a controlled transition to turbulence, enhancing lift and stability in various flight conditions but generally increasing drag compared to laminar designs.

Table of Comparison

| Feature | Laminar Flow Airfoil | Turbulent Flow Airfoil |

|---|---|---|

| Flow Type | Smooth, orderly airflow with minimal mixing | Chaotic, mixed airflow with higher momentum exchange |

| Drag Characteristics | Lower skin friction drag, improved fuel efficiency | Higher skin friction drag, increased fuel consumption |

| Lift-to-Drag Ratio | Higher L/D ratio, better aerodynamic efficiency | Lower L/D ratio, reduced aerodynamic efficiency |

| Surface Sensitivity | Highly sensitive to surface roughness and contamination | Less sensitive, maintains performance with minor surface imperfections |

| Operational Range | Best suited for low to moderate speeds | Effective across wide speed ranges, including high speeds |

| Stall Behavior | Sharp stall onset, less forgiving | Smoother stall, more gradual loss of lift |

| Typical Applications | Gliders, high-efficiency light aircraft | Commercial jets, fighter aircraft |

Introduction to Airfoil Flow Dynamics

Laminar flow airfoils maintain smooth, orderly airflow over the wing surface, significantly reducing skin friction drag and improving aerodynamic efficiency. Turbulent flow airfoils experience chaotic, mixed airflow that increases drag but enhances boundary layer stability, delaying flow separation and stall. Understanding these flow dynamics helps optimize your airfoil design for specific performance goals, balancing drag reduction with stall resistance.

What is Laminar Flow in Airfoils?

Laminar flow in airfoils refers to a smooth, orderly airflow pattern where air particles move in parallel layers with minimal mixing or disruption, reducing skin friction drag. This type of flow typically occurs at lower angles of attack and Reynolds numbers, promoting higher aerodynamic efficiency and improved fuel economy in aircraft design. Maintaining laminar flow over the airfoil surface can significantly enhance lift-to-drag ratio and overall performance compared to turbulent flow airfoils.

Understanding Turbulent Flow in Airfoils

Turbulent flow airfoils are designed to manage chaotic and irregular airflow patterns that increase energy loss but enhance surface momentum, improving lift at higher angles of attack. Understanding turbulent flow in airfoils is crucial for optimizing performance in conditions where airflow separation and drag are significant concerns. Your choice between laminar and turbulent flow airfoils depends on balancing low drag benefits with stability and control in real-world aerodynamic environments.

Key Differences: Laminar vs. Turbulent Flow Airfoils

Laminar flow airfoils maintain smooth, orderly airflow over a larger portion of the wing, reducing skin friction drag and enhancing fuel efficiency, while turbulent flow airfoils promote controlled mixing of airflow that delays flow separation, improving stall characteristics and stability. Your choice between these airfoil types depends on performance priorities such as low drag for high-speed flight or better control at slower speeds. Designing with laminar flow airfoils often demands stricter surface finish and maintenance to preserve aerodynamic advantages compared to the more forgiving turbulent flow airfoils.

Aerodynamic Efficiency: Performance Comparisons

Laminar flow airfoils exhibit lower skin friction drag due to smoother airflow, resulting in higher aerodynamic efficiency compared to turbulent flow airfoils. Turbulent flow airfoils, while experiencing increased drag, maintain better boundary layer adherence and delay flow separation, enhancing performance at higher angles of attack. Overall, laminar flow designs optimize glide ratio and fuel efficiency in steady, low-turbulence conditions, whereas turbulent flow airfoils offer greater stability and control robustness under varied flight regimes.

Effects on Drag and Lift

Laminar flow airfoils maintain smooth, orderly airflow over the surface, significantly reducing skin friction drag and improving overall aerodynamic efficiency. In contrast, turbulent flow airfoils create a chaotic boundary layer that increases drag but enhances lift by delaying flow separation, improving stability at higher angles of attack. Your choice between laminar and turbulent flow airfoils directly impacts the balance of lift generation and drag reduction critical for aircraft performance.

Design Considerations for Laminar and Turbulent Airfoils

Design considerations for laminar flow airfoils emphasize maintaining smooth airflow by minimizing surface roughness and controlling pressure gradients to delay boundary layer transition. Turbulent flow airfoils prioritize robustness against flow separation and improved performance under varied Reynolds numbers by promoting energetic boundary layers that resist adverse pressure gradients. Optimizing your airfoil selection depends on balancing efficiency gains from laminar flow with the stability and durability benefits of turbulent flow designs.

Applications in Modern Aircraft

Laminar flow airfoils reduce drag by maintaining smooth airflow, enhancing fuel efficiency in gliders and high-performance commercial jets. Turbulent flow airfoils provide better control and stability, making them ideal for fighter jets and aerobatic aircraft operating under varied conditions. Your choice between these airfoil types impacts aircraft performance, fuel consumption, and mission capability.

Maintenance and Operational Implications

Laminar flow airfoils reduce skin friction drag by maintaining smooth airflow, resulting in improved fuel efficiency and lower operational costs over time. Turbulent flow airfoils, while generating higher drag, provide increased stability and are less sensitive to surface contamination or damage, leading to reduced maintenance frequency. Your choice affects inspection schedules and upkeep expenses, balancing efficiency gains with durability and maintenance demands.

Future Trends in Airfoil Flow Technology

Future trends in airfoil flow technology emphasize the integration of hybrid laminar flow control (HLFC) systems to maximize aerodynamic efficiency and reduce drag. Advances in adaptive materials and smart surface coatings enable real-time manipulation of boundary layer characteristics, promoting sustained laminar flow over greater chord lengths. Computational fluid dynamics (CFD) innovations and machine learning algorithms drive optimized airfoil designs, balancing laminar and turbulent flow benefits for next-generation aircraft performance and fuel savings.

laminar flow airfoil vs turbulent flow airfoil Infographic

libmatt.com

libmatt.com