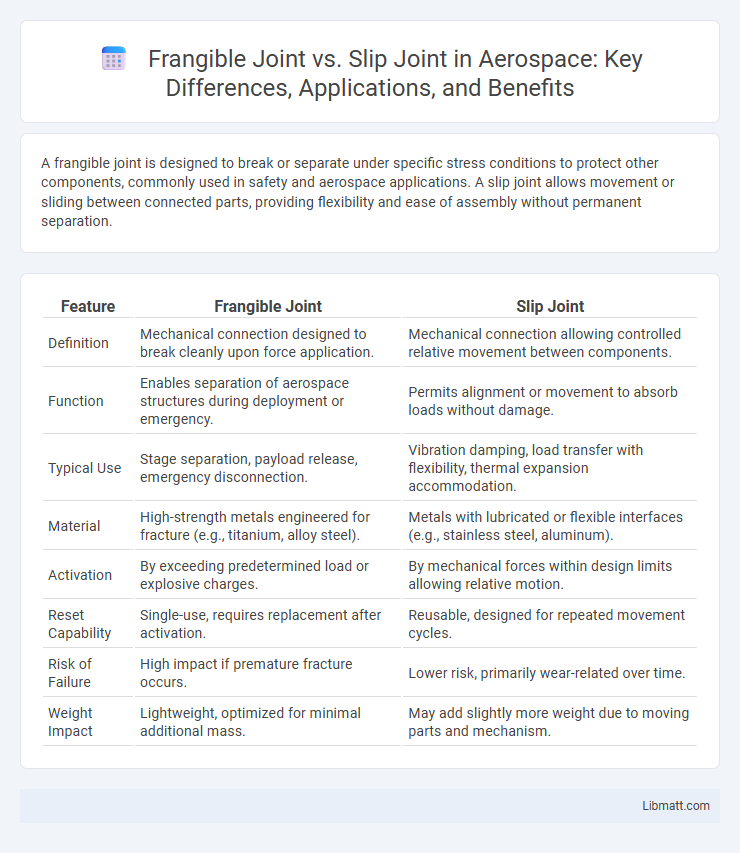

A frangible joint is designed to break or separate under specific stress conditions to protect other components, commonly used in safety and aerospace applications. A slip joint allows movement or sliding between connected parts, providing flexibility and ease of assembly without permanent separation.

Table of Comparison

| Feature | Frangible Joint | Slip Joint |

|---|---|---|

| Definition | Mechanical connection designed to break cleanly upon force application. | Mechanical connection allowing controlled relative movement between components. |

| Function | Enables separation of aerospace structures during deployment or emergency. | Permits alignment or movement to absorb loads without damage. |

| Typical Use | Stage separation, payload release, emergency disconnection. | Vibration damping, load transfer with flexibility, thermal expansion accommodation. |

| Material | High-strength metals engineered for fracture (e.g., titanium, alloy steel). | Metals with lubricated or flexible interfaces (e.g., stainless steel, aluminum). |

| Activation | By exceeding predetermined load or explosive charges. | By mechanical forces within design limits allowing relative motion. |

| Reset Capability | Single-use, requires replacement after activation. | Reusable, designed for repeated movement cycles. |

| Risk of Failure | High impact if premature fracture occurs. | Lower risk, primarily wear-related over time. |

| Weight Impact | Lightweight, optimized for minimal additional mass. | May add slightly more weight due to moving parts and mechanism. |

Introduction to Frangible and Slip Joints

Frangible joints are designed to break or separate under specific stress or pressure to prevent damage to other components in a system, commonly used in aerospace and automotive applications for safety purposes. Slip joints allow relative movement between connected parts, providing flexibility and ease of assembly, widely utilized in plumbing and mechanical systems to accommodate thermal expansion or misalignment. Both joint types serve distinct functions in mechanical design, emphasizing controlled failure and movement respectively.

Definition of Frangible Joints

Frangible joints are specially designed connections that break or separate under predetermined stress or impact, ensuring controlled failure in structural applications. They are commonly used in safety and aerospace industries to prevent damage and facilitate maintenance by allowing quick disassembly. Your choice between frangible joints and slip joints depends on whether you need a joint that fails predictably or one that allows movement without separation.

Definition of Slip Joints

Slip joints are mechanical connections that allow for slight movement or adjustment between two components, typically used in plumbing to enable easy assembly and disassembly without the need for permanent sealing methods. Unlike frangible joints, which are designed to break under specific conditions to protect a system, slip joints maintain flexibility and allow for realignment or absorption of thermal expansion. Understanding the definition and function of slip joints helps you select the appropriate fitting for applications requiring frequent maintenance or minor positional adjustments.

Key Differences Between Frangible and Slip Joints

Frangible joints are designed to break under specific stress to prevent damage to connected systems, commonly used in piping and safety devices, while slip joints allow telescoping movement to accommodate expansion or contraction in plumbing systems. The key difference lies in functionality; frangible joints sacrifice structural integrity to protect the system, whereas slip joints maintain integrity and flexibility without failure. Understanding these distinctions helps you select the appropriate joint type for safety or structural adaptability in your project.

Applications of Frangible Joints

Frangible joints are primarily used in aerospace, defense, and safety-critical applications where controlled separation upon impact or specific stress conditions is essential. These joints enable components to break apart cleanly without damaging adjacent structures, making them ideal for emergency release systems, detachable payloads, and controlled explosive devices. Understanding their function enhances your ability to select the right joint type for scenarios requiring precise, safe disconnection.

Applications of Slip Joints

Slip joints are widely used in plumbing systems to provide easy disassembly and realignment of pipes, essential for maintenance and repairs in residential and commercial buildings. They are commonly found in sink drains, traps, and vent piping where flexibility and adjustability are required to accommodate slight misalignments or movement. Their ability to create a watertight seal without permanent connections makes slip joints ideal for accessible areas needing frequent access or adjustments.

Advantages of Frangible Joints

Frangible joints offer significant advantages in applications requiring precise failure points, as they provide controlled and predictable separation under stress, enhancing safety and reliability. These joints reduce the risk of unintended detachment by utilizing engineered weak points that maintain structural integrity until a specific load threshold is met. Compared to slip joints, frangible joints minimize maintenance needs and improve performance in critical aerospace, automotive, and industrial systems by ensuring rapid and clean separation when necessary.

Advantages of Slip Joints

Slip joints offer superior flexibility and ease of installation, making them ideal for plumbing repairs and adjustments. Their design allows quick disassembly and reassembly without specialized tools, saving time and effort during maintenance. You benefit from reliable leak resistance and adaptability to minor misalignments in pipes, enhancing overall system durability.

Common Materials Used for Each Joint

Frangible joints commonly use materials such as aluminum alloys, polymers, and composites designed to break cleanly under stress, ensuring controlled separation in aerospace or automotive applications. Slip joints typically utilize metals like stainless steel or brass combined with flexible rubber or plastic seals, providing durable, movable connections in plumbing and mechanical systems. Understanding the materials in your specific joint type helps optimize performance and enables proper maintenance for reliable operation.

Choosing Between Frangible and Slip Joints

Choosing between frangible and slip joints depends on the specific application requirements such as load tolerance, environmental conditions, and ease of maintenance. Frangible joints are designed to break or separate under predetermined stress to protect surrounding components, making them ideal for safety-critical applications. Slip joints allow limited movement and flexibility, providing easier assembly and adjustment in piping or mechanical systems where slight displacement is expected.

Frangible Joint vs Slip Joint Infographic

libmatt.com

libmatt.com