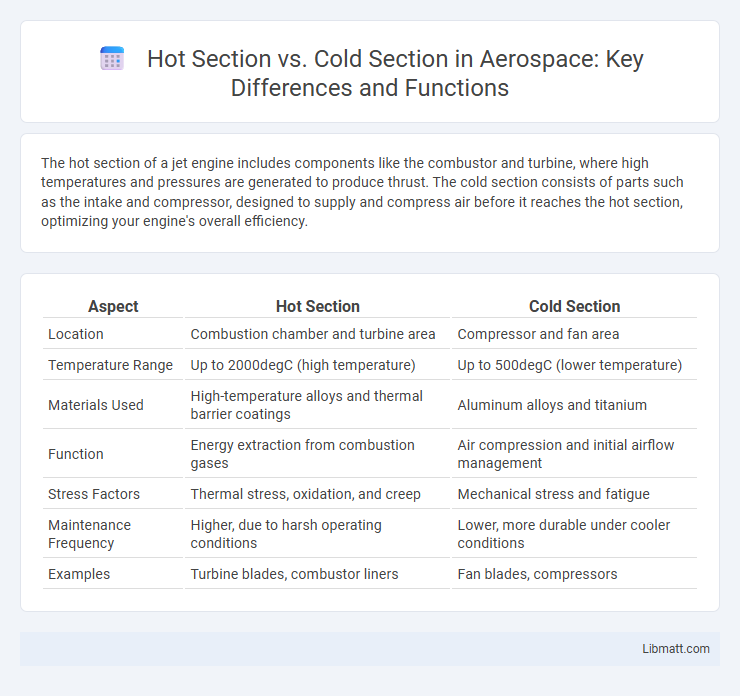

The hot section of a jet engine includes components like the combustor and turbine, where high temperatures and pressures are generated to produce thrust. The cold section consists of parts such as the intake and compressor, designed to supply and compress air before it reaches the hot section, optimizing your engine's overall efficiency.

Table of Comparison

| Aspect | Hot Section | Cold Section |

|---|---|---|

| Location | Combustion chamber and turbine area | Compressor and fan area |

| Temperature Range | Up to 2000degC (high temperature) | Up to 500degC (lower temperature) |

| Materials Used | High-temperature alloys and thermal barrier coatings | Aluminum alloys and titanium |

| Function | Energy extraction from combustion gases | Air compression and initial airflow management |

| Stress Factors | Thermal stress, oxidation, and creep | Mechanical stress and fatigue |

| Maintenance Frequency | Higher, due to harsh operating conditions | Lower, more durable under cooler conditions |

| Examples | Turbine blades, combustor liners | Fan blades, compressors |

Introduction to Hot Section vs Cold Section

The hot section of a gas turbine engine includes components exposed to high temperatures, such as the combustion chamber and turbine blades, which operate under extreme thermal and mechanical stress. The cold section consists of parts like the compressor and air intake, where air is cooler and operates at higher pressure but lower temperature. Understanding the difference between hot and cold sections is crucial for optimizing engine performance, efficiency, and maintenance strategies for your gas turbine system.

Defining Hot Section and Cold Section

Hot section refers to the part of a gas turbine engine where high-temperature combustion gases flow, including components such as the combustion chamber, turbine blades, and nozzle guide vanes that operate under extreme thermal stress. Cold section encompasses the areas exposed to lower temperatures, primarily the compressor, inlet, and casing, which handle air intake and compression before combustion occurs. Distinguishing these sections is critical for engineering materials selection and thermal management in turbine design.

Key Components of the Hot Section

The hot section of a gas turbine primarily includes the combustor, turbine blades, and nozzle guide vanes, which operate under extremely high temperatures often exceeding 1,500degC. These components are constructed from advanced heat-resistant materials like superalloys and employ sophisticated cooling techniques to withstand thermal stress and maintain efficiency. Understanding the functionality and durability of these critical parts is essential for optimizing your turbine's performance and extending its operational lifespan.

Key Components of the Cold Section

The cold section of a gas turbine includes key components such as the air intake, compressor, and combustion chamber. The air intake directs ambient air into the system while the compressor increases the air pressure before combustion. Your gas turbine's efficiency heavily relies on the performance and maintenance of these cold section components.

Temperature Differences: Hot vs Cold Section

The hot section of a gas turbine operates at temperatures exceeding 1,000degC, crucial for maximizing thermal efficiency and power output, while the cold section maintains much lower temperatures around 200-400degC to protect components and enhance durability. Temperature gradients between the hot and cold sections necessitate advanced materials and cooling technologies to withstand thermal stress and prevent failure. Managing these temperature differences is essential for optimizing performance and extending the lifespan of turbine components.

Material Selection for Hot and Cold Sections

Material selection for the hot section prioritizes high-temperature resistance, thermal stability, and oxidation resistance, using superalloys like Inconel and nickel-based alloys to withstand extreme combustion temperatures. In contrast, materials for the cold section focus on corrosion resistance, fatigue strength, and weight reduction, typically employing titanium alloys, stainless steel, and aluminum alloys due to lower operating temperatures. The contrast in thermal and mechanical demands drives the distinct material choices to optimize performance and durability in gas turbine engines.

Performance Impact of Hot and Cold Sections

The hot section of a gas turbine experiences extreme temperatures and directly affects thermal efficiency and component durability, driving overall performance. The cold section, operating at lower temperatures, influences airflow stability and mechanical reliability, impacting compressor efficiency and turbine inlet conditions. Optimizing the thermal and aerodynamic design of both sections is crucial to maximizing power output and fuel efficiency while minimizing maintenance costs.

Maintenance Challenges: Hot vs Cold Section

Maintenance challenges in the hot section of a gas turbine include frequent exposure to high temperatures leading to thermal fatigue, oxidation, and blade creep, requiring specialized materials and cooling techniques. The cold section experiences fewer thermal stresses but faces issues such as dirt accumulation, corrosion, and mechanical wear, necessitating routine inspections and cleaning. Understanding these distinctions helps optimize your maintenance schedule, prolonging turbine life and improving operational efficiency.

Applications in Modern Turbine Engines

The hot section of modern turbine engines, including the combustor and turbine blades, operates at extremely high temperatures and is designed to withstand intense thermal stress for efficient energy conversion. The cold section, comprising components like the compressor and intake, handles airflow management and operates at significantly lower temperatures, optimizing air compression and preparation before combustion. Advances in materials science and cooling technologies have enhanced the durability and performance of both sections, enabling higher engine efficiency and reduced emissions in aerospace and power generation applications.

Future Developments in Hot and Cold Sections

Future developments in hot sections focus on advanced materials like ceramic matrix composites to withstand higher temperatures and improve turbine efficiency. Cold section innovations include enhanced cooling techniques and lightweight alloys for better durability and performance. Your engine's overall efficiency will benefit from integrating these cutting-edge technologies in both hot and cold sections.

Hot section vs Cold section Infographic

libmatt.com

libmatt.com