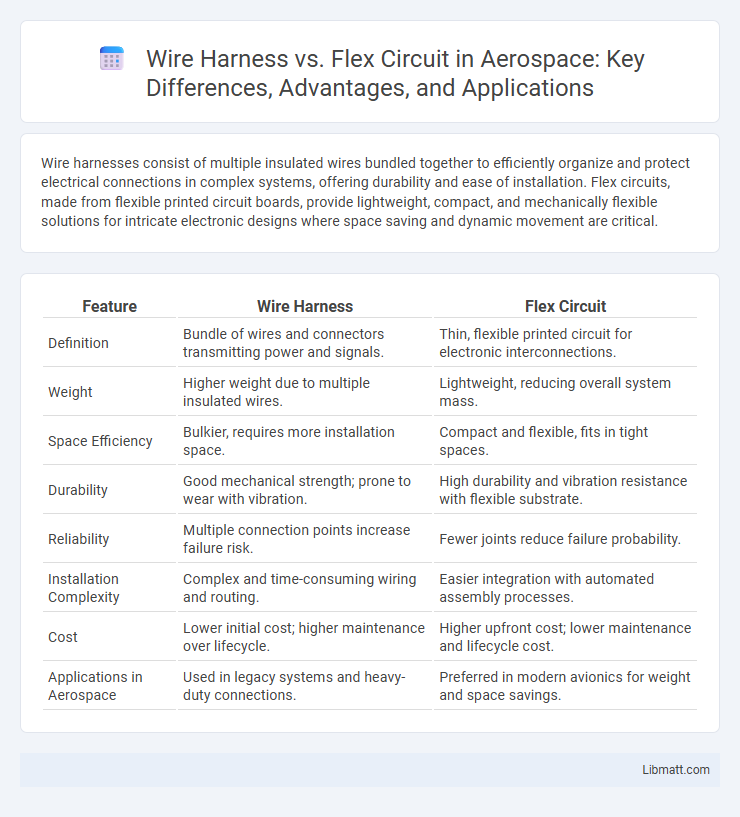

Wire harnesses consist of multiple insulated wires bundled together to efficiently organize and protect electrical connections in complex systems, offering durability and ease of installation. Flex circuits, made from flexible printed circuit boards, provide lightweight, compact, and mechanically flexible solutions for intricate electronic designs where space saving and dynamic movement are critical.

Table of Comparison

| Feature | Wire Harness | Flex Circuit |

|---|---|---|

| Definition | Bundle of wires and connectors transmitting power and signals. | Thin, flexible printed circuit for electronic interconnections. |

| Weight | Higher weight due to multiple insulated wires. | Lightweight, reducing overall system mass. |

| Space Efficiency | Bulkier, requires more installation space. | Compact and flexible, fits in tight spaces. |

| Durability | Good mechanical strength; prone to wear with vibration. | High durability and vibration resistance with flexible substrate. |

| Reliability | Multiple connection points increase failure risk. | Fewer joints reduce failure probability. |

| Installation Complexity | Complex and time-consuming wiring and routing. | Easier integration with automated assembly processes. |

| Cost | Lower initial cost; higher maintenance over lifecycle. | Higher upfront cost; lower maintenance and lifecycle cost. |

| Applications in Aerospace | Used in legacy systems and heavy-duty connections. | Preferred in modern avionics for weight and space savings. |

Introduction to Wire Harnesses and Flex Circuits

Wire harnesses are assemblies of insulated wires bundled together to transmit electrical power or signals, commonly used in automotive and aerospace industries for organizing complex wiring systems. Flex circuits, also known as flexible printed circuits, are thin, flexible electronics made of conductive traces on a flexible substrate, offering lightweight and space-saving connections in compact devices like smartphones and medical equipment. Your choice between wire harnesses and flex circuits depends on factors such as space constraints, flexibility requirements, and application environment.

Key Differences Between Wire Harnesses and Flex Circuits

Wire harnesses consist of multiple insulated wires bundled together to transmit electrical power and signals, offering flexibility for complex routing in automotive and industrial applications. Flex circuits, made from thin, flexible polymer substrates with etched copper traces, provide high-density, lightweight connections ideal for compact electronics and precise signal integrity. Your choice depends on factors like space constraints, durability requirements, and electrical performance needs.

Materials Used in Wire Harnesses vs Flex Circuits

Wire harnesses primarily use insulated copper or aluminum wires bundled together with protective sleeves made from materials like PVC, nylon, or Teflon to ensure durability and flexibility in various environments. Flex circuits are composed of thin, flexible polyimide or polyester substrates with etched copper traces, offering lightweight and compact interconnections suitable for complex electronic assemblies. The choice of materials in wire harnesses emphasizes mechanical protection and ease of maintenance, whereas flex circuits prioritize electrical performance and space-saving design.

Design and Flexibility Considerations

Wire harnesses offer customizable routing for complex electrical systems, making them ideal for applications requiring durable, high-current connections. Flex circuits provide superior flexibility and lightweight design, enabling integration into compact or dynamic spaces with repeated bending. Your choice depends on design constraints, mechanical stress tolerance, and space optimization needs.

Space and Weight Efficiency Comparison

Flex circuits offer superior space and weight efficiency compared to wire harnesses due to their thin, lightweight, and flexible design, allowing for compact and intricate routing in tight spaces. Wire harnesses tend to be bulkier and heavier because of the multiple insulated wires bundled together, which can limit design flexibility and increase overall system weight. In aerospace and medical device applications, flex circuits are preferred for reducing space constraints and enhancing performance by minimizing wiring mass.

Electrical Performance and Reliability

Wire harnesses offer robust electrical performance with excellent current-carrying capacity and durability in harsh environments, ensuring reliable connections for automotive and industrial applications. Flex circuits provide superior signal integrity and reduced electromagnetic interference due to their thin, flexible substrate and precise conductor paths, making them ideal for compact electronics. Both technologies enhance reliability, but flex circuits excel in minimizing weight and space while maintaining consistent electrical performance in complex, high-density assemblies.

Installation and Maintenance Factors

Wire harnesses offer straightforward installation with standardized connectors and are easier to repair or modify due to their discrete wiring. Flex circuits require precise handling during installation because of their delicate flexible substrates but offer reduced weight and space-saving advantages. Your choice impacts maintenance complexity, with wire harnesses allowing simpler troubleshooting compared to the often more intricate repairs needed for flex circuits.

Cost Implications: Wire Harness vs Flex Circuit

Wire harnesses typically incur higher labor costs due to complex assembly processes, while flex circuits offer cost advantages through automated production and reduced material usage. The initial tooling investment for flex circuits can be substantial, but economies of scale lower per-unit costs in high-volume manufacturing. Maintenance and repair expenses are generally lower with wire harnesses because of their modular design, whereas flex circuits may require complete replacement if damaged, impacting long-term cost considerations.

Typical Applications and Industries

Wire harnesses are predominantly used in automotive, aerospace, and industrial machinery for reliable power distribution and signal transmission in complex wiring systems. Flex circuits are favored in consumer electronics, medical devices, and wearable technology due to their lightweight, space-saving, and flexible design. Your choice depends on the application's need for durability, space constraints, and flexibility, with wire harnesses suited for heavy-duty environments and flex circuits ideal for compact, dynamic devices.

Selecting the Right Solution for Your Project

Choosing between a wire harness and a flex circuit depends on factors like space constraints, flexibility needs, and electrical complexity. Wire harnesses excel in durability and ease of repair for larger, less compact designs, while flex circuits offer miniaturization and high-density interconnections ideal for compact, flexible applications. Evaluating environmental conditions, mechanical stress, and signal requirements ensures the right solution optimizes performance and reliability for your project.

wire harness vs flex circuit Infographic

libmatt.com

libmatt.com