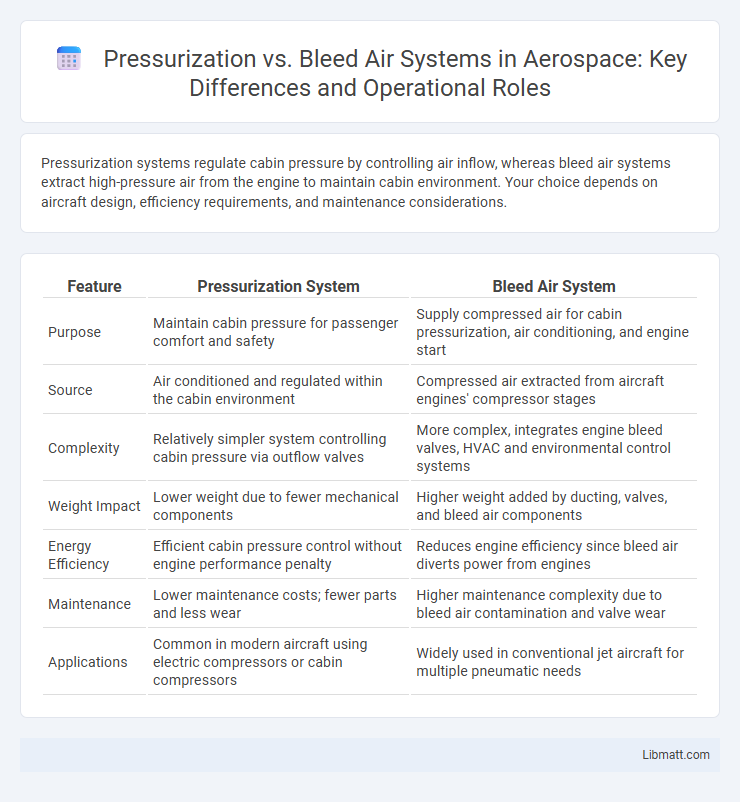

Pressurization systems regulate cabin pressure by controlling air inflow, whereas bleed air systems extract high-pressure air from the engine to maintain cabin environment. Your choice depends on aircraft design, efficiency requirements, and maintenance considerations.

Table of Comparison

| Feature | Pressurization System | Bleed Air System |

|---|---|---|

| Purpose | Maintain cabin pressure for passenger comfort and safety | Supply compressed air for cabin pressurization, air conditioning, and engine start |

| Source | Air conditioned and regulated within the cabin environment | Compressed air extracted from aircraft engines' compressor stages |

| Complexity | Relatively simpler system controlling cabin pressure via outflow valves | More complex, integrates engine bleed valves, HVAC and environmental control systems |

| Weight Impact | Lower weight due to fewer mechanical components | Higher weight added by ducting, valves, and bleed air components |

| Energy Efficiency | Efficient cabin pressure control without engine performance penalty | Reduces engine efficiency since bleed air diverts power from engines |

| Maintenance | Lower maintenance costs; fewer parts and less wear | Higher maintenance complexity due to bleed air contamination and valve wear |

| Applications | Common in modern aircraft using electric compressors or cabin compressors | Widely used in conventional jet aircraft for multiple pneumatic needs |

Introduction to Aircraft Cabin Systems

Aircraft cabin systems include pressurization and bleed air systems, essential for maintaining a safe and comfortable environment at high altitudes. Pressurization systems regulate cabin pressure to simulate lower altitudes for passenger comfort and physiological needs. Bleed air systems extract hot, compressed air from the engine compressors to supply air for pressurization, ventilation, and environmental control.

Overview of Pressurization Systems

Pressurization systems control the cabin air pressure to maintain a safe and comfortable environment at high altitudes by regulating the flow of compressed air, typically sourced from the engine's bleed air. These systems monitor and adjust cabin pressure using outflow valves and cabin pressure controllers to prevent rapid altitude changes that can affect passenger comfort and safety. Understanding your aircraft's pressurization system ensures optimal performance and compliance with aviation safety standards.

Understanding Bleed Air Systems

Bleed air systems draw high-pressure air from aircraft engines to maintain cabin pressurization by regulating air pressure and temperature. This system ensures a continuous supply of conditioned air that supports passenger comfort and safety at high altitudes. Compared to alternative methods, bleed air systems offer reliability but require monitoring for potential contamination and efficiency losses.

Key Components of Pressurization and Bleed Air

Pressurization systems consist of key components such as outflow valves, cabin pressure controllers, and air conditioning packs that regulate and maintain optimal cabin pressure. Bleed air systems utilize bleed valves, pneumatic ducts, and air extractors to capture high-pressure air from the engine compressors for pressurization and air conditioning. Understanding the interaction of these components is essential for maintaining your aircraft's cabin comfort and safety during flight.

How Pressurization Systems Work

Pressurization systems maintain cabin altitude by regulating airflow from the engines or an auxiliary power unit, controlling the pressure inside the aircraft cabin to ensure passenger comfort and safety. Air is compressed and conditioned before being introduced into the cabin, while outflow valves modulate the pressure by releasing air to maintain a balanced environment. Understanding how pressurization systems work helps you appreciate the technology that keeps cabin pressure stable during varying flight altitudes.

Bleed Air System Functions and Operations

Bleed air systems extract high-pressure air from engine compressors to supply cabin pressurization, anti-icing, and air conditioning. This system regulates cabin pressure by controlling airflow through outflow valves, maintaining safe and comfortable atmospheric conditions at high altitudes. Efficient bleed air management enhances engine performance while ensuring adequate environmental control within the aircraft.

Comparative Analysis: Pressurization vs Bleed Air

Pressurization systems use dedicated compressors to maintain aircraft cabin pressure independently, improving efficiency and reducing fuel consumption compared to traditional bleed air systems, which draw high-pressure air from the engines. Bleed air systems increase engine workload and temperature management challenges, potentially affecting engine performance and maintenance intervals. Modern aircraft increasingly favor pressurization systems due to their capability to optimize environmental control while minimizing impact on engine operation.

Safety Considerations for Both Systems

Pressurization and bleed air systems each have distinct safety considerations vital to aircraft operation. Bleed air systems rely on high-pressure air from the engines, posing risks of contamination and fire hazards if leaks occur, while pressurization systems must precisely control cabin pressure to prevent hypoxia or structural damage during altitude changes. Both require rigorous monitoring and maintenance protocols to ensure system integrity, minimize failure risks, and safeguard passenger and crew health.

Efficiency and Maintenance Differences

Pressurization systems using electric compressors often yield higher efficiency by reducing fuel consumption compared to traditional bleed air systems that divert engine air. Maintenance requirements for electric pressurization are generally lower due to fewer mechanical components exposed to high temperatures and pressures. Your choice between these systems impacts operational costs and reliability, with electric systems offering a more modern, cost-effective solution.

Future Trends in Aircraft Cabin Environmental Control

Future trends in aircraft cabin environmental control emphasize electrically driven pressurization systems over traditional bleed air systems to improve fuel efficiency and reduce maintenance complexity. Advanced electric compressors enable precise cabin pressure modulation and enhance air quality by minimizing contamination risks inherent in bleed air sourced from engine compressors. Integration of sustainable technologies and real-time data analytics supports adaptive environmental control, optimizing passenger comfort and reducing overall environmental impact.

pressurization vs bleed air systems Infographic

libmatt.com

libmatt.com