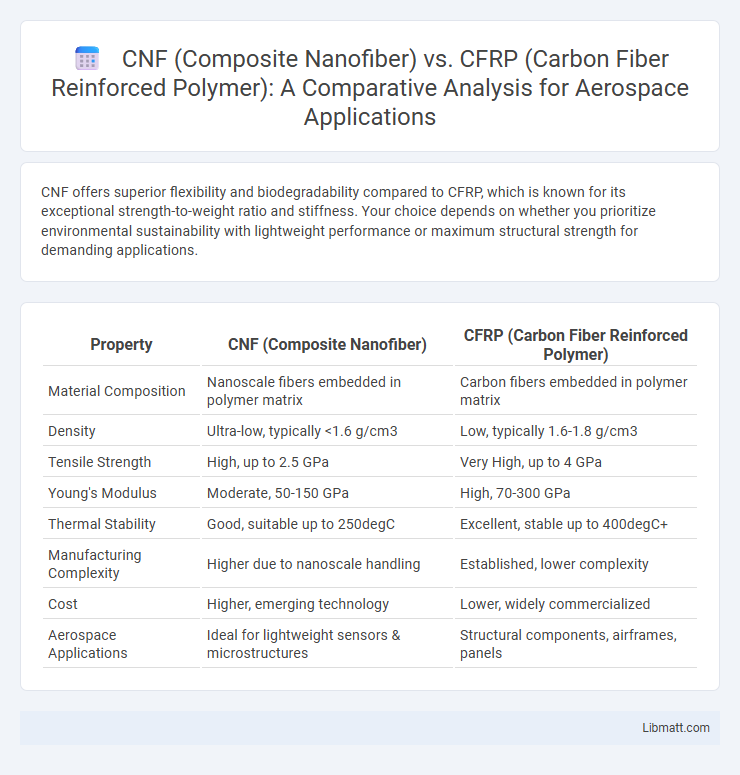

CNF offers superior flexibility and biodegradability compared to CFRP, which is known for its exceptional strength-to-weight ratio and stiffness. Your choice depends on whether you prioritize environmental sustainability with lightweight performance or maximum structural strength for demanding applications.

Table of Comparison

| Property | CNF (Composite Nanofiber) | CFRP (Carbon Fiber Reinforced Polymer) |

|---|---|---|

| Material Composition | Nanoscale fibers embedded in polymer matrix | Carbon fibers embedded in polymer matrix |

| Density | Ultra-low, typically <1.6 g/cm3 | Low, typically 1.6-1.8 g/cm3 |

| Tensile Strength | High, up to 2.5 GPa | Very High, up to 4 GPa |

| Young's Modulus | Moderate, 50-150 GPa | High, 70-300 GPa |

| Thermal Stability | Good, suitable up to 250degC | Excellent, stable up to 400degC+ |

| Manufacturing Complexity | Higher due to nanoscale handling | Established, lower complexity |

| Cost | Higher, emerging technology | Lower, widely commercialized |

| Aerospace Applications | Ideal for lightweight sensors & microstructures | Structural components, airframes, panels |

Introduction to Advanced Composite Materials

Composite Nanofiber (CNF) and Carbon Fiber Reinforced Polymer (CFRP) represent advanced composite materials with distinct structural advantages; CNFs provide superior surface area and nanoscale reinforcement enhancing mechanical, thermal, and electrical properties, while CFRPs offer high strength-to-weight ratios crucial for aerospace and automotive applications. Your choice between CNF and CFRP depends on the specific performance requirements, such as flexibility, conductivity, or structural rigidity, with CNFs excelling in multifunctional applications and CFRPs in load-bearing structures. Integrating these materials in innovative designs pushes the boundaries of lightweight, high-performance composites ideal for cutting-edge engineering challenges.

Overview of Composite Nanofiber (CNF)

Composite Nanofiber (CNF) materials consist of nanoscale fibers embedded within a polymer matrix, offering exceptional strength-to-weight ratios and enhanced mechanical properties compared to traditional composites. CNFs exhibit superior surface area and improved interfacial bonding, leading to increased durability, flexibility, and resistance to fatigue. Their nanoscale dimensions enable applications in aerospace, automotive, and biomedical fields where lightweight, high-performance materials are critical.

Fundamentals of Carbon Fiber Reinforced Polymer (CFRP)

Carbon Fiber Reinforced Polymer (CFRP) consists of carbon fiber reinforcements embedded within a polymer matrix, providing exceptional strength-to-weight ratio and stiffness. The carbon fibers serve as the primary load-bearing component, while the polymer matrix distributes stress and protects fibers from environmental damage and fatigue. Your selection of CFRP materials enables the creation of lightweight, high-performance structures widely used in aerospace, automotive, and sporting industries.

Material Composition and Structure: CNF vs CFRP

Composite Nanofibers (CNF) consist of nanoscale fibers often made from polymers, ceramics, or carbon, characterized by their extremely high surface area and uniform nanoscale diameter that enhances mechanical and functional properties. Carbon Fiber Reinforced Polymer (CFRP) combines carbon fibers with a polymer matrix, providing high strength and stiffness due to the continuous carbon fibers embedded in the resin. Your choice between CNF and CFRP depends on required material properties like weight, strength, and specific structural applications.

Mechanical Properties and Performance Comparison

Composite Nanofibers (CNF) exhibit exceptional tensile strength and high surface area-to-volume ratio, enhancing mechanical interlocking and load transfer efficiency compared to Carbon Fiber Reinforced Polymers (CFRP). CFRP typically offers superior stiffness and fatigue resistance due to the inherent properties of carbon fibers embedded in a polymer matrix, making it ideal for aerospace and automotive applications. CNF composites often demonstrate improved impact resistance and flexibility, but CFRP outperforms CNF in overall structural rigidity and long-term durability under cyclic loading conditions.

Manufacturing Processes and Techniques

Composite Nanofiber (CNF) manufacturing involves electrospinning techniques that produce ultrafine fibers with high surface area for enhanced mechanical and functional properties, allowing precise control over fiber diameter and alignment. Carbon Fiber Reinforced Polymer (CFRP) fabrication utilizes processes such as resin transfer molding (RTM), autoclave curing, and filament winding to integrate carbon fibers within a polymer matrix, achieving high strength-to-weight ratios and tailored structural performance. CNF production emphasizes nanoscale fiber fabrication often in lab-scale or specialized applications, while CFRP manufacturing targets large-scale industrial composites for aerospace, automotive, and construction sectors.

Applications in Aerospace, Automotive, and Industry

CNF (Composite Nanofiber) offers lightweight, high surface area materials enhancing impact resistance and thermal stability, making it ideal for aerospace components requiring fatigue durability and vibration damping. CFRP (Carbon Fiber Reinforced Polymer) provides superior tensile strength and stiffness, widely used in automotive structural parts, aerospace airframes, and industrial machinery for weight reduction and performance optimization. Both materials contribute to advanced manufacturing in industries focused on fuel efficiency, mechanical resilience, and sustainable material solutions.

Environmental Impact and Sustainability

CNF (Composite Nanofiber) offers a significantly lower environmental impact compared to CFRP (Carbon Fiber Reinforced Polymer) due to its bio-based and biodegradable components, which enhance sustainability by reducing carbon footprint and waste accumulation. CFRP production relies heavily on energy-intensive processes and non-renewable petroleum-based materials, leading to challenges in recycling and long-term environmental degradation. Choosing CNF for your applications supports greener manufacturing practices and contributes to circular economy goals through renewable resource utilization and easier end-of-life management.

Cost Analysis and Market Trends

Composite Nanofibers (CNF) generally exhibit lower production costs compared to Carbon Fiber Reinforced Polymers (CFRP) due to less energy-intensive manufacturing processes and the use of more abundant raw materials. Market trends indicate a growing interest in CNF for applications requiring high surface area and flexibility, while CFRP maintains dominance in aerospace and automotive sectors due to its superior mechanical strength and proven performance. Cost analysis and evolving market demands suggest CNF is gaining traction in niche areas, potentially disrupting certain composite markets as scalability improves.

Future Prospects and Innovations

Composite Nanofiber (CNF) materials exhibit promising future prospects due to their exceptional mechanical strength, lightweight properties, and enhanced thermal stability compared to traditional Carbon Fiber Reinforced Polymers (CFRP). Innovations in CNF involve nano-scale surface modification techniques and hybrid composites that improve interfacial bonding, leading to superior durability and multifunctionality in aerospace and automotive applications. Emerging research also highlights CNF's potential for sustainable production through bio-based sources, addressing environmental concerns tied to CFRP manufacturing and recycling challenges.

CNF (Composite Nanofiber) vs CFRP (Carbon Fiber Reinforced Polymer) Infographic

libmatt.com

libmatt.com