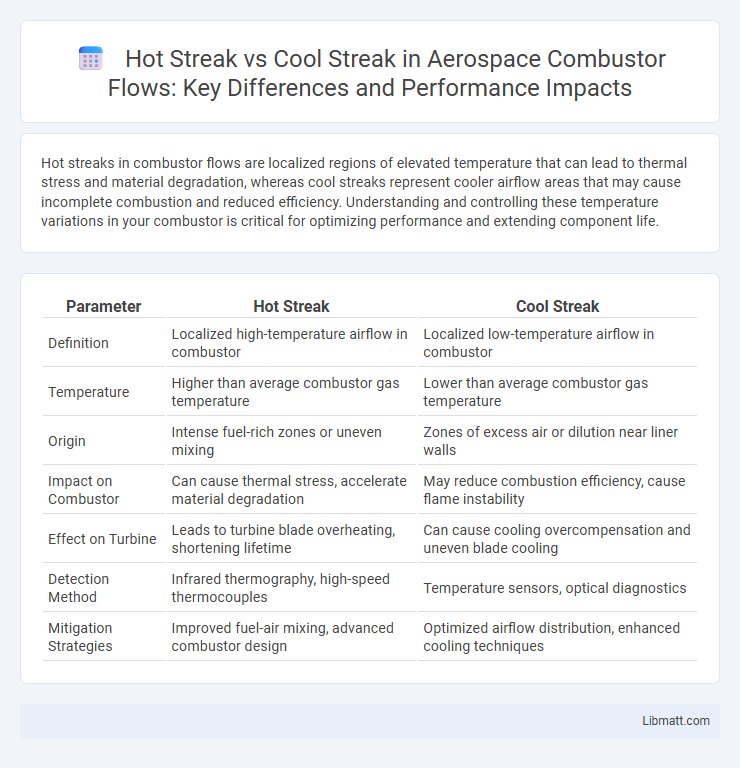

Hot streaks in combustor flows are localized regions of elevated temperature that can lead to thermal stress and material degradation, whereas cool streaks represent cooler airflow areas that may cause incomplete combustion and reduced efficiency. Understanding and controlling these temperature variations in your combustor is critical for optimizing performance and extending component life.

Table of Comparison

| Parameter | Hot Streak | Cool Streak |

|---|---|---|

| Definition | Localized high-temperature airflow in combustor | Localized low-temperature airflow in combustor |

| Temperature | Higher than average combustor gas temperature | Lower than average combustor gas temperature |

| Origin | Intense fuel-rich zones or uneven mixing | Zones of excess air or dilution near liner walls |

| Impact on Combustor | Can cause thermal stress, accelerate material degradation | May reduce combustion efficiency, cause flame instability |

| Effect on Turbine | Leads to turbine blade overheating, shortening lifetime | Can cause cooling overcompensation and uneven blade cooling |

| Detection Method | Infrared thermography, high-speed thermocouples | Temperature sensors, optical diagnostics |

| Mitigation Strategies | Improved fuel-air mixing, advanced combustor design | Optimized airflow distribution, enhanced cooling techniques |

Introduction to Streaks in Combustor Flows

Streaks in combustor flows represent elongated regions of altered velocity and temperature that significantly impact mixing and flame stability. Hot streaks are high-temperature regions formed by incomplete mixing or localized heat release, while cool streaks consist of relatively cooler and slower fluid patches. Understanding your combustor's streak behavior is crucial for optimizing combustion efficiency and minimizing emissions.

Defining Hot Streaks and Cool Streaks

Hot streaks in combustor flows refer to localized regions of elevated temperature caused by uneven fuel-air mixing or combustion instabilities, leading to thermal gradients that can impact turbine component life. Cool streaks are areas of lower temperature within the combustor, often resulting from airflow patterns or fuel injection irregularities, which affect combustion efficiency and emissions. Both hot and cool streaks influence the uniformity of temperature distribution critical for optimal combustor performance and durability.

Formation Mechanisms of Temperature Streaks

Hot streaks in combustor flows form due to localized regions of incomplete mixing between fuel and air, causing concentrated zones of high temperature linked to flamelet structures and swirling flow patterns. Cool streaks arise from regions of entrained cooler air or dilution holes, resulting in lower temperature streaks influenced by aerodynamic effects and thermal boundary layers. The interaction between turbulence and swirl dynamics drives the spatial distribution and persistence of these temperature streaks, impacting overall combustor performance and emissions.

Impact of Hot Streaks on Combustor Performance

Hot streaks in combustor flows cause uneven temperature distributions that significantly impact your engine's thermal efficiency and component durability. These localized high-temperature regions increase thermal stresses on turbine blades, accelerating material degradation and reducing overall combustor performance. Managing hot streak intensity and distribution is crucial for optimizing combustion stability and extending engine life.

Effects of Cool Streaks in Combustion Chambers

Cool streaks in combustion chambers significantly enhance flame stability by reducing localized temperatures and mitigating thermal NOx formation. These lower-temperature regions promote better mixing of fuel and air, improving combustion efficiency and extending the lifespan of combustor components. Understanding how cool streaks influence flow dynamics enables you to optimize combustor design for reduced emissions and improved thermal management.

Streak Behavior and Flow Dynamics

Hot streaks in combustor flows are high-temperature fluid regions originating from localized heat release, exhibiting coherent, elongated structures that significantly impact turbine blade heating and lifespan. Cool streaks, conversely, are cooler fluid patterns often associated with flow mixing and dilution zones, promoting temperature uniformity and reducing thermal stress on components. The interaction between hot and cool streaks influences turbulence intensity, flow stability, and overall combustor efficiency by affecting heat transfer and combustion dynamics.

Thermal Mixing and Uniformity Challenges

Hot streaks in combustor flows create localized thermal peaks that disrupt uniform temperature distribution, leading to uneven thermal mixing and increased risk of hot spots on turbine blades. Cool streaks introduce regions of lower temperature, which can cause incomplete combustion and instabilities in the flow pattern, further complicating thermal uniformity. Achieving optimal thermal mixing demands advanced flow control strategies to mitigate the effects of both hot and cool streaks, ensuring consistent temperature profiles for efficient combustor operation.

Measurement Techniques for Streak Detection

Measurement techniques for detecting hot streaks and cool streaks in combustor flows primarily involve advanced diagnostics such as particle image velocimetry (PIV) and laser-induced fluorescence (LIF), capturing high-resolution velocity and temperature distributions. Infrared thermography and fast-response thermocouples provide complementary temperature data to pinpoint thermal gradients critical for identifying streaks. Your effective streak detection relies on integrating these techniques to resolve transient flow patterns and accurately assess combustion stability.

Mitigation Strategies for Streak Management

Mitigation strategies for managing hot streaks and cool streaks in combustor flows focus on flow conditioning techniques such as advanced air injection and fuel staging to promote uniform temperature distributions. Implementation of swirlers and film cooling enhances mixing characteristics, reducing thermal gradients and minimizing combustion instability linked to streaks. Computational fluid dynamics (CFD) tools enable precise modeling and optimization of combustor geometries to control streak intensity and improve overall combustor performance.

Future Research Directions in Combustor Streaks

Future research directions in combustor streaks emphasize advanced diagnostics and predictive modeling to capture the transient behavior of hot streaks and cool streaks under varied operating conditions. High-fidelity simulations coupled with machine learning algorithms aim to improve the understanding of streak evolution, interactions, and their impact on turbine blade thermal loads. You can expect studies to focus on three-dimensional flow structures and real-time control strategies for optimizing combustor performance and durability.

Hot Streak vs Cool Streak (combustor flows) Infographic

libmatt.com

libmatt.com