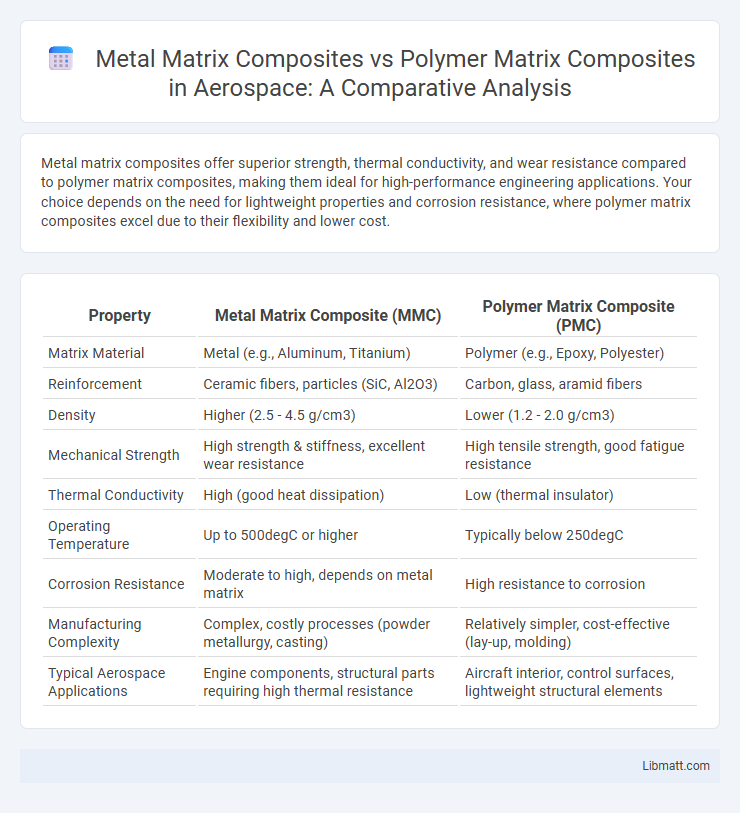

Metal matrix composites offer superior strength, thermal conductivity, and wear resistance compared to polymer matrix composites, making them ideal for high-performance engineering applications. Your choice depends on the need for lightweight properties and corrosion resistance, where polymer matrix composites excel due to their flexibility and lower cost.

Table of Comparison

| Property | Metal Matrix Composite (MMC) | Polymer Matrix Composite (PMC) |

|---|---|---|

| Matrix Material | Metal (e.g., Aluminum, Titanium) | Polymer (e.g., Epoxy, Polyester) |

| Reinforcement | Ceramic fibers, particles (SiC, Al2O3) | Carbon, glass, aramid fibers |

| Density | Higher (2.5 - 4.5 g/cm3) | Lower (1.2 - 2.0 g/cm3) |

| Mechanical Strength | High strength & stiffness, excellent wear resistance | High tensile strength, good fatigue resistance |

| Thermal Conductivity | High (good heat dissipation) | Low (thermal insulator) |

| Operating Temperature | Up to 500degC or higher | Typically below 250degC |

| Corrosion Resistance | Moderate to high, depends on metal matrix | High resistance to corrosion |

| Manufacturing Complexity | Complex, costly processes (powder metallurgy, casting) | Relatively simpler, cost-effective (lay-up, molding) |

| Typical Aerospace Applications | Engine components, structural parts requiring high thermal resistance | Aircraft interior, control surfaces, lightweight structural elements |

Introduction to Metal Matrix Composites and Polymer Matrix Composites

Metal Matrix Composites (MMCs) consist of metal alloys reinforced with ceramic fibers or particles to enhance strength, stiffness, and thermal conductivity, making them ideal for aerospace and automotive applications. Polymer Matrix Composites (PMCs) incorporate polymer resins reinforced with fibers like carbon or glass, offering lightweight properties, corrosion resistance, and ease of fabrication for use in sports equipment, automotive, and construction. Both MMCs and PMCs provide tailored mechanical properties through their distinct matrix and reinforcement combinations, optimizing performance for specific engineering needs.

Key Differences Between MMCs and PMCs

Metal Matrix Composites (MMCs) offer higher strength, thermal conductivity, and wear resistance compared to Polymer Matrix Composites (PMCs), which are lighter and exhibit better corrosion resistance and flexibility. MMCs typically utilize aluminum, titanium, or magnesium matrices reinforced with ceramic fibers or particles, while PMCs combine polymer matrices such as epoxy or polyester with carbon or glass fibers. The key differences lie in their mechanical properties, thermal behavior, and application fields, with MMCs favored in aerospace and automotive sectors requiring high load-bearing capacity and PMCs preferred in lightweight, corrosion-sensitive environments.

Composition and Structure Comparison

Metal Matrix Composites (MMCs) consist of a metallic matrix combined with reinforcing materials such as ceramic fibers or particles, providing high strength, stiffness, and thermal resistance. Polymer Matrix Composites (PMCs) feature a polymer resin matrix reinforced with fibers like carbon or glass, offering lightweight properties and excellent corrosion resistance. Your choice between MMCs and PMCs depends on the required mechanical performance, operating temperatures, and environmental conditions.

Mechanical Properties of MMCs vs PMCs

Metal Matrix Composites (MMCs) exhibit superior mechanical properties compared to Polymer Matrix Composites (PMCs), including higher tensile strength, stiffness, and thermal conductivity. MMCs also demonstrate better impact resistance and fatigue life due to their metal reinforcement, making them suitable for high-performance, load-bearing applications. However, PMCs offer greater corrosion resistance and lighter weight, which can be advantageous in aerospace and automotive components requiring reduced mass.

Thermal Conductivity and Stability

Metal Matrix Composites (MMCs) exhibit superior thermal conductivity, often exceeding 100 W/m*K, making them ideal for high-heat applications, while Polymer Matrix Composites (PMCs) generally have lower thermal conductivity, typically below 1 W/m*K, limiting their use in thermal management. MMCs maintain excellent thermal stability at elevated temperatures, often above 500degC, due to their metallic constituents, whereas PMCs degrade at lower temperatures, typically around 200-300degC, constraining their performance in high-temperature environments. The inherent thermal properties of MMCs enable better heat dissipation and dimensional stability under thermal stress compared to the insulating nature and thermal degradation susceptibility of PMCs.

Corrosion Resistance and Environmental Performance

Metal Matrix Composites (MMCs) typically exhibit superior corrosion resistance compared to Polymer Matrix Composites (PMCs) due to their metallic constituents forming protective oxide layers in harsh environments. However, PMCs often outperform MMCs in environmental performance by offering better resistance to UV radiation, chemical exposure, and moisture degradation, making them more durable under certain conditions. Your choice between MMC and PMC should consider the specific environmental factors and corrosion exposure of your application to optimize longevity.

Manufacturing Processes and Techniques

Metal Matrix Composites (MMCs) are typically manufactured using processes such as powder metallurgy, squeeze casting, and infiltration, enabling high-temperature resistance and superior mechanical properties. Polymer Matrix Composites (PMCs) are primarily fabricated through techniques like hand lay-up, filament winding, and resin transfer molding, offering lightweight and corrosion-resistant advantages. Choosing the right manufacturing process depends on your application's performance requirements, production volume, and cost constraints.

Cost and Availability Factors

Metal Matrix Composites (MMCs) generally incur higher costs due to expensive raw materials and complex manufacturing processes compared to Polymer Matrix Composites (PMCs), which benefit from widely available polymers and simpler fabrication techniques. The availability of PMC materials is broader, supporting mass production and cost efficiency, while MMCs are often limited by the need for specialized alloys and precise processing conditions. Industries prioritize PMCs for cost-sensitive applications, whereas MMCs are reserved for high-performance needs despite their higher price and lower availability.

Common Applications in Industry

Metal Matrix Composites (MMCs) are widely used in aerospace, automotive, and defense industries due to their high strength, thermal conductivity, and wear resistance, making them ideal for engine components, brake rotors, and armor. Polymer Matrix Composites (PMCs) excel in aerospace, marine, and sports equipment sectors, offering lightweight properties and corrosion resistance, which are crucial for aircraft fuselages, boat hulls, and high-performance sporting goods. Choosing between MMCs and PMCs depends on your specific application requirements such as load-bearing capacity, environmental exposure, and cost efficiency.

Future Trends and Innovations in Composite Materials

Future trends in metal matrix composites (MMCs) emphasize enhanced thermal stability, high strength-to-weight ratios, and wear resistance for aerospace and automotive applications, driven by advancements in nano-reinforcement technologies. Polymer matrix composites (PMCs) are evolving with innovations in bio-based resins and additive manufacturing, offering sustainable solutions alongside improved mechanical performance and damage tolerance. Cross-disciplinary research integrating smart materials and multifunctional composites is accelerating development of hybrid composites combining MMC and PMC advantages for next-generation lightweight, high-performance materials.

Metal Matrix Composite vs Polymer Matrix Composite Infographic

libmatt.com

libmatt.com