Hybrid laminar flow combines natural laminar flow with active control methods like suction to reduce boundary layer turbulence, enhancing aerodynamic efficiency beyond natural laminar flow alone, which relies solely on smooth surface contours to maintain laminar airflow. Your aircraft's fuel efficiency and performance can significantly improve with hybrid laminar flow technology by minimizing drag more effectively than natural laminar flow.

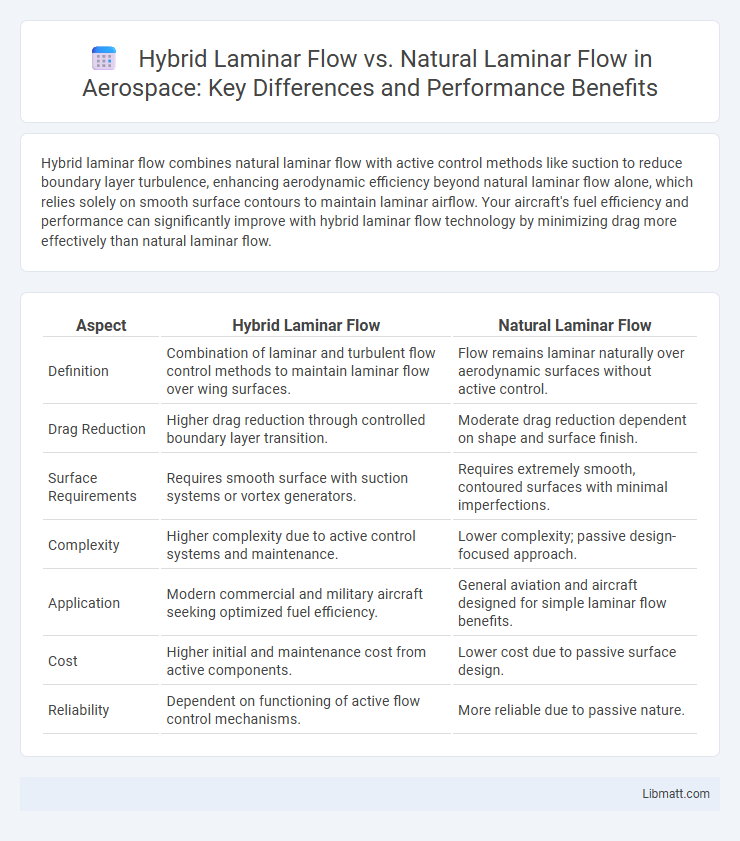

Table of Comparison

| Aspect | Hybrid Laminar Flow | Natural Laminar Flow |

|---|---|---|

| Definition | Combination of laminar and turbulent flow control methods to maintain laminar flow over wing surfaces. | Flow remains laminar naturally over aerodynamic surfaces without active control. |

| Drag Reduction | Higher drag reduction through controlled boundary layer transition. | Moderate drag reduction dependent on shape and surface finish. |

| Surface Requirements | Requires smooth surface with suction systems or vortex generators. | Requires extremely smooth, contoured surfaces with minimal imperfections. |

| Complexity | Higher complexity due to active control systems and maintenance. | Lower complexity; passive design-focused approach. |

| Application | Modern commercial and military aircraft seeking optimized fuel efficiency. | General aviation and aircraft designed for simple laminar flow benefits. |

| Cost | Higher initial and maintenance cost from active components. | Lower cost due to passive surface design. |

| Reliability | Dependent on functioning of active flow control mechanisms. | More reliable due to passive nature. |

Introduction to Laminar Flow in Aerodynamics

Laminar flow in aerodynamics refers to smooth, orderly airflow over a surface, characterized by low skin friction and reduced drag compared to turbulent flow. Natural laminar flow (NLF) occurs without external influence, relying on surface shape and pressure gradients to maintain laminar conditions, often used in aircraft wing design to improve fuel efficiency. Hybrid laminar flow combines passive laminar shaping with active flow control techniques, such as suction, to extend laminar regions and further reduce drag in high-performance aerospace applications.

Defining Natural Laminar Flow (NLF)

Natural Laminar Flow (NLF) refers to the ability of an aircraft's wing or surface to maintain smooth, laminar airflow over a significant portion of its surface without external manipulation, reducing drag and improving fuel efficiency. This type of laminar flow relies on optimized airfoil shapes and surface smoothness to delay transition from laminar to turbulent flow under natural flight conditions. NLF is contrasted with Hybrid Laminar Flow Control (HLFC), which uses suction or other active techniques to extend laminar flow regions beyond what NLF can achieve passively.

Understanding Hybrid Laminar Flow (HLF)

Hybrid Laminar Flow (HLF) combines natural laminar flow characteristics with active flow control techniques to reduce drag and enhance aerodynamic efficiency on aircraft surfaces. By integrating passive shaping and suction systems, HLF maintains smooth airflow longer along the wing, delaying transition from laminar to turbulent flow. This approach improves fuel efficiency and performance compared to traditional natural laminar flow wings, especially in varying flight conditions.

Key Differences Between NLF and HLF

Natural Laminar Flow (NLF) maintains smooth airflow over aircraft surfaces by minimizing disturbances, enhancing aerodynamic efficiency through careful wing shaping to delay laminar-to-turbulent transition. Hybrid Laminar Flow (HLF) combines passive design features with active suction or boundary layer control techniques, offering improved laminar flow extent compared to NLF alone. Understanding these key differences helps optimize your aircraft's performance by selecting the appropriate laminar flow technology for specific mission profiles.

Design Principles for NLF and HLF

Natural Laminar Flow (NLF) design principles emphasize maintaining smooth, low-disturbance surfaces to ensure laminar flow over the wing by carefully controlling pressure gradients and minimizing surface roughness. Hybrid Laminar Flow (HLF) combines these design features with active or passive methods, such as suction or optimized wing geometry, to extend laminar regions under practical flight conditions. Your choice between NLF and HLF impacts aerodynamic efficiency, with HLF often providing enhanced drag reduction by addressing boundary layer transition more robustly than purely natural methods.

Performance Benefits of Laminar Flow Technologies

Hybrid laminar flow combines regions of natural laminar flow with localized laminar flow control methods, reducing skin friction drag more effectively than natural laminar flow alone, which relies solely on maintaining smooth airflow over surfaces. This technology enhances fuel efficiency and extends aircraft range by minimizing turbulent airflow, particularly on wing leading edges or fuselage sections designed for laminar transition control. Improved aerodynamic performance through hybrid laminar flow results in lower emissions and operational costs, making it a vital advancement in modern aerospace design.

Challenges in Maintaining Laminar Flow

Maintaining laminar flow in hybrid laminar flow (HLF) systems faces challenges such as surface contamination, pressure gradients, and aerodynamic disturbances that disrupt smooth airflow. In natural laminar flow (NLF) designs, airfoil shape optimization is critical to minimize boundary layer transition, but susceptibility to environmental factors like insect strikes and surface roughness complicates sustained laminar conditions. Both HLF and NLF require precise surface quality control and advanced materials to reduce turbulence and ensure efficient flow maintenance.

Applications in Aviation and Aerospace

Hybrid laminar flow (HLFC) systems combine natural laminar flow (NLF) with active flow control technologies to reduce drag on aircraft surfaces, leading to improved fuel efficiency and extended range. While natural laminar flow relies on smooth aerodynamic designs to maintain laminar airflow passively, hybrid approaches use suction or other mechanisms to stabilize the boundary layer under more varied flight conditions, making them especially valuable for high-speed commercial jets and next-generation aerospace vehicles. Your investment in hybrid laminar flow technology can enhance aircraft performance, reduce emissions, and contribute to sustainable aviation advancements.

Cost and Maintenance Considerations

Hybrid laminar flow systems typically involve more complex technologies such as active boundary layer control and require specialized maintenance, resulting in higher operational costs compared to natural laminar flow designs. Natural laminar flow surfaces rely on passive aerodynamic shaping, leading to lower maintenance demands and cost savings over the aircraft's lifecycle. Cost efficiency for hybrid systems depends on the balance between fuel savings from improved laminar flow and the increased expenses related to upkeep and system complexity.

Future Developments in Laminar Flow Technology

Future developments in laminar flow technology emphasize enhancing hybrid laminar flow control (HLFC) systems by integrating advanced suction mechanisms and adaptive surface materials to achieve greater drag reduction compared to natural laminar flow (NLF) designs. Research on smart coatings and real-time flow sensors aims to optimize boundary layer management, facilitating extended laminar flow regions even under turbulent conditions. These innovations promise significant improvements in aerodynamic efficiency for next-generation aircraft, reducing fuel consumption and emissions.

hybrid laminar flow vs natural laminar flow Infographic

libmatt.com

libmatt.com