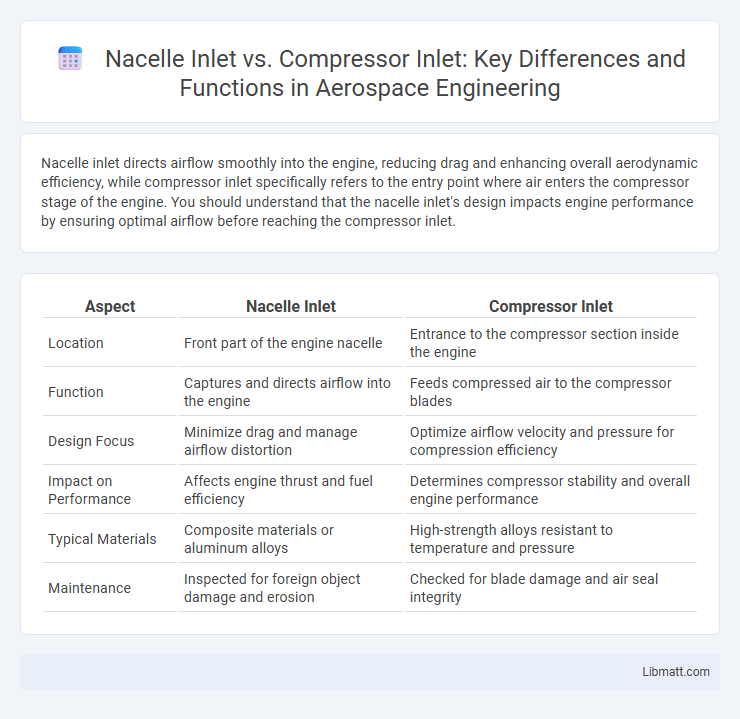

Nacelle inlet directs airflow smoothly into the engine, reducing drag and enhancing overall aerodynamic efficiency, while compressor inlet specifically refers to the entry point where air enters the compressor stage of the engine. You should understand that the nacelle inlet's design impacts engine performance by ensuring optimal airflow before reaching the compressor inlet.

Table of Comparison

| Aspect | Nacelle Inlet | Compressor Inlet |

|---|---|---|

| Location | Front part of the engine nacelle | Entrance to the compressor section inside the engine |

| Function | Captures and directs airflow into the engine | Feeds compressed air to the compressor blades |

| Design Focus | Minimize drag and manage airflow distortion | Optimize airflow velocity and pressure for compression efficiency |

| Impact on Performance | Affects engine thrust and fuel efficiency | Determines compressor stability and overall engine performance |

| Typical Materials | Composite materials or aluminum alloys | High-strength alloys resistant to temperature and pressure |

| Maintenance | Inspected for foreign object damage and erosion | Checked for blade damage and air seal integrity |

Introduction to Nacelle Inlet and Compressor Inlet

The nacelle inlet is a critical component that directs airflow efficiently into the engine, shaping the aerodynamic profile of the aircraft's engine housing. The compressor inlet, located inside the nacelle, precisely controls the air entering the compressor stage to optimize engine performance and prevent flow distortions. Understanding the differences between these two inlets helps you evaluate engine efficiency and aircraft design for improved propulsion systems.

Role of Inlet Systems in Aircraft Engines

Nacelle inlets play a critical role in directing and managing airflow efficiently into the engine, reducing drag and minimizing pressure losses to enhance overall propulsion performance. Compressor inlets are specifically designed to ensure uniform and stable airflow enters the compressor, optimizing compression efficiency and preventing airflow distortions or surges. Together, these inlet systems maintain engine reliability and thrust generation by controlling airflow dynamics under various flight conditions.

Nacelle Inlet: Structure and Function

The nacelle inlet serves as the aerodynamic entry point of an aircraft engine, designed to efficiently channel airflow while reducing drag and minimizing turbulence. Its smooth, contoured structure optimizes pressure recovery and protects the engine core by filtering out debris and foreign objects. You benefit from enhanced engine performance and fuel efficiency due to the nacelle inlet's precise engineering and functional design.

Compressor Inlet: Structure and Function

The compressor inlet is designed to optimize airflow into the compressor, featuring components such as guide vanes and flow straighteners to reduce turbulence and ensure uniform air distribution. Its primary function is to increase the pressure and velocity of incoming air, improving engine efficiency and performance. Unlike the nacelle inlet, which serves as an aerodynamic housing that channels air smoothly, the compressor inlet directly interfaces with the compressor blades to facilitate effective compression processes.

Key Differences Between Nacelle and Compressor Inlets

The nacelle inlet is the external aerodynamic structure designed to efficiently channel airflow into the engine, optimizing drag reduction and noise suppression, while the compressor inlet is an internal component directly feeding air into the compressor stages for combustion. Nacelle inlets manage environmental factors such as bird strikes and weather, ensuring stable airflow quality, whereas compressor inlets focus on maintaining pressure and temperature conditions essential for engine performance. Key differences include their location, functional objectives--external airflow management versus internal engine intake--and impact on overall engine efficiency and reliability.

Aerodynamic Considerations for Inlet Design

Nacelle inlet design plays a critical role in optimizing airflow to the engine compressor, minimizing turbulence and pressure losses for improved engine performance. Aerodynamic considerations focus on shaping the nacelle inlet to ensure smooth, uniform airflow distribution while preventing flow separation and distortion at varying flight conditions. Your engine's efficiency and operability depend heavily on the precision of this aerodynamic design, directly impacting fuel consumption and thrust generation.

Impact on Engine Performance: Nacelle vs Compressor

Nacelle inlets are designed to optimize airflow before it reaches the compressor, reducing drag and enhancing overall engine efficiency. Compressor inlets directly influence the pressure and temperature of air entering the compressor stages, significantly impacting thrust and fuel consumption. Your engine's performance depends on both inlets working synergistically to maximize aerodynamic flow and minimize energy losses.

Materials and Manufacturing Differences

Nacelle inlets are typically constructed from lightweight composite materials such as carbon fiber or fiberglass to optimize aerodynamic efficiency and reduce overall aircraft weight, using advanced molding and curing processes. Compressor inlets, on the other hand, often employ high-strength metals like aluminum alloys or titanium to withstand extreme pressure and temperature conditions within the engine, requiring precision machining and heat treatment during manufacturing. Your choice between the two depends on balancing factors like weight savings, durability, and environmental exposure in engine design.

Common Challenges and Solutions in Inlet Design

Nacelle inlet and compressor inlet designs both face challenges such as airflow distortion, pressure loss, and foreign object damage risk, which impact engine performance and durability. Solutions include implementing carefully contoured inlet lips and boundary layer diverters in nacelle inlets to ensure smooth airflow, while compressor inlets benefit from advanced flow control devices and filtration systems to protect against debris and maintain uniform pressure distribution. Optimizing inlet geometry with computational fluid dynamics (CFD) simulations helps minimize distortions and pressure drops, enhancing overall engine efficiency and reliability.

Future Trends in Inlet Technology

Future trends in nacelle inlet and compressor inlet technology focus on improving aerodynamic efficiency, reducing noise, and enhancing engine performance under diverse flight conditions. Advances in adaptive and morphing inlet designs use smart materials and real-time sensor feedback to optimize airflow and minimize drag, directly contributing to fuel savings and environmental sustainability. Your aircraft's engine efficiency will benefit significantly as these intelligent inlet systems evolve, integrating seamlessly with next-generation propulsion technology.

Nacelle inlet vs Compressor inlet Infographic

libmatt.com

libmatt.com