High bypass turbofan engines provide greater fuel efficiency and quieter operation by channeling most air around the engine core, making them ideal for commercial airliners. Low bypass engines have a smaller air bypass ratio, delivering higher thrust and better performance for military jets and supersonic aircraft where speed and maneuverability are crucial.

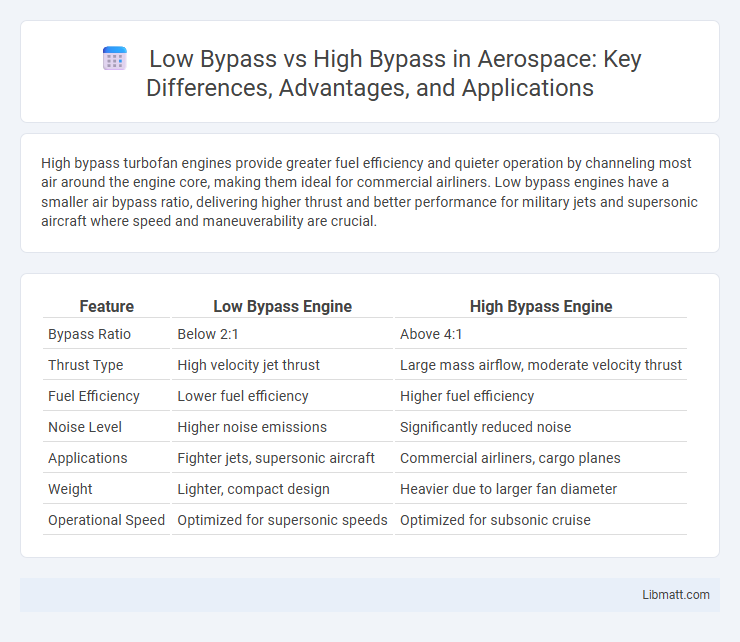

Table of Comparison

| Feature | Low Bypass Engine | High Bypass Engine |

|---|---|---|

| Bypass Ratio | Below 2:1 | Above 4:1 |

| Thrust Type | High velocity jet thrust | Large mass airflow, moderate velocity thrust |

| Fuel Efficiency | Lower fuel efficiency | Higher fuel efficiency |

| Noise Level | Higher noise emissions | Significantly reduced noise |

| Applications | Fighter jets, supersonic aircraft | Commercial airliners, cargo planes |

| Weight | Lighter, compact design | Heavier due to larger fan diameter |

| Operational Speed | Optimized for supersonic speeds | Optimized for subsonic cruise |

Understanding Bypass Ratios in Jet Engines

Bypass ratio in jet engines measures the amount of air bypassing the engine core relative to the air passing through it, directly influencing fuel efficiency and thrust. Low bypass engines generate higher thrust and are suited for supersonic speeds, while high bypass engines offer better fuel economy and quieter operation for commercial aviation. Understanding these differences helps optimize your choice based on performance needs and operational priorities.

What is Low Bypass?

Low bypass turbofan engines feature a smaller portion of air bypassing the engine core, typically with a bypass ratio less than 4:1, resulting in higher exhaust velocities and greater thrust efficiency at high speeds. These engines prioritize performance and fuel efficiency in military and supersonic aircraft by producing significant thrust with a compact design. Low bypass engines excel in scenarios demanding rapid acceleration and high-speed operation but generate more noise and consume more fuel compared to high bypass variants.

What is High Bypass?

High bypass refers to a type of turbofan engine design where the majority of the air propelled by the fan bypasses the engine core, resulting in greater fuel efficiency and quieter operation. This design is characterized by a large fan diameter that moves a significant volume of air around the combustion chamber, enhancing thrust and reducing specific fuel consumption. Your choice of high bypass engines is ideal for commercial airliners seeking improved performance on long-haul flights with reduced environmental impact.

Key Differences Between Low and High Bypass Engines

Low bypass engines have a smaller fan diameter and a higher exhaust velocity, producing greater thrust suitable for supersonic speeds and military applications. High bypass engines feature larger fans that move more air around the core, resulting in improved fuel efficiency, reduced noise, and better performance for commercial and long-haul aircraft. Understanding the key differences between low and high bypass engines helps you choose the right propulsion system based on your aircraft's mission profile and efficiency needs.

Thrust Generation: Low vs High Bypass

Low bypass engines generate thrust primarily through high-velocity exhaust gases from the core, resulting in higher specific thrust and better performance at supersonic speeds. High bypass engines produce most of their thrust by accelerating a large mass of air around the core, offering greater fuel efficiency, quieter operation, and improved thrust at subsonic speeds. Understanding the thrust generation differences helps you choose the right engine type for performance requirements in commercial or military aviation.

Fuel Efficiency Comparisons

Low bypass turbofan engines offer higher fuel efficiency at supersonic speeds due to reduced drag and better thrust output, making them suitable for military and some business jets. High bypass engines are more fuel-efficient at subsonic speeds, as the larger volume of bypass air improves propulsive efficiency and reduces specific fuel consumption, benefiting commercial airliners on long-haul flights. Your choice between low bypass and high bypass engines directly impacts fuel economy based on the typical cruise speed and mission profile of the aircraft.

Noise Levels and Environmental Impact

High bypass engines generate significantly lower noise levels compared to low bypass engines due to their larger fan diameter and slower airflow, which reduces jet noise and enhances passenger comfort. The increased bypass ratio also improves fuel efficiency, resulting in lower carbon emissions and a reduced environmental footprint. When selecting an engine for your aircraft, a high bypass engine offers a quieter operation and greater sustainability, meeting stricter noise regulations and environmental standards.

Applications: Military vs Commercial Aircraft

Low bypass engines are preferred in military aircraft due to their higher thrust-to-weight ratio and superior performance at supersonic speeds, enabling rapid acceleration and agility essential for combat missions. High bypass engines dominate commercial aviation because their larger fan diameter provides enhanced fuel efficiency, reduced noise levels, and lower emissions, aligning with the operational priorities of long-haul passenger flights. The trade-off between thrust and efficiency distinctly separates low bypass turbofans for tactical applications from high bypass turbofans optimized for economic and environmental considerations in commercial aircraft.

Maintenance and Operational Considerations

Low bypass engines tend to have higher fuel consumption and require more frequent maintenance due to their hotter operating temperatures and increased mechanical stress. High bypass engines offer improved fuel efficiency and longer intervals between overhauls, resulting in lower overall operational costs. Maintenance schedules for high bypass turbofans are optimized for extended engine life, reducing downtime and enhancing fleet availability.

Future Trends in Bypass Engine Technology

High bypass engines dominate modern commercial aviation due to their superior fuel efficiency and lower noise levels, but future trends indicate a shift toward ultra-high bypass ratios combined with advanced materials like carbon composites to further reduce emissions. You can expect developments in geared turbofan designs to optimize performance and enable quieter operation, aligning with stricter environmental regulations and sustainability goals. Innovations in hybrid-electric propulsion systems also promise to complement high bypass engines, enhancing fuel efficiency while minimizing the carbon footprint of future aircraft.

low bypass vs high bypass Infographic

libmatt.com

libmatt.com