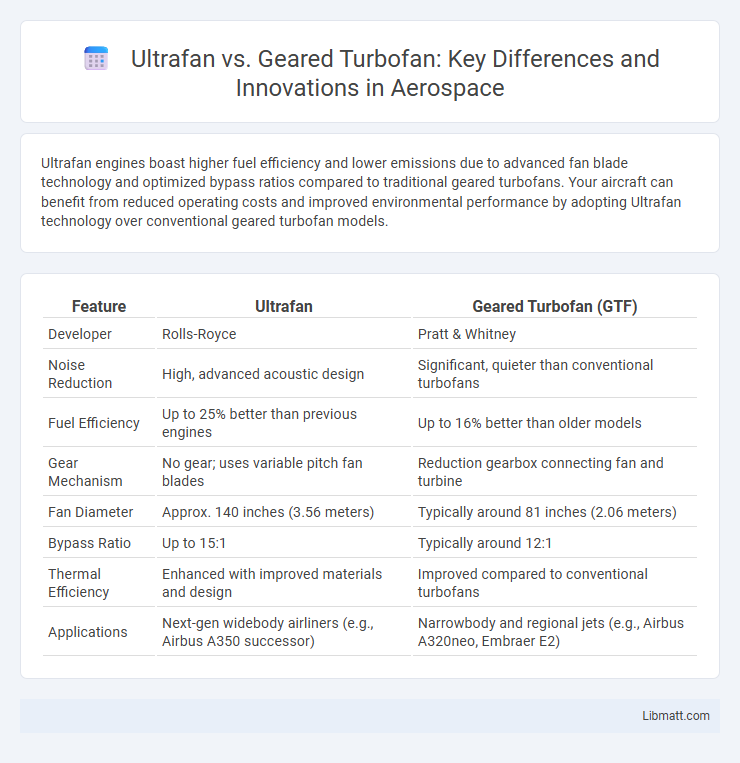

Ultrafan engines boast higher fuel efficiency and lower emissions due to advanced fan blade technology and optimized bypass ratios compared to traditional geared turbofans. Your aircraft can benefit from reduced operating costs and improved environmental performance by adopting Ultrafan technology over conventional geared turbofan models.

Table of Comparison

| Feature | Ultrafan | Geared Turbofan (GTF) |

|---|---|---|

| Developer | Rolls-Royce | Pratt & Whitney |

| Noise Reduction | High, advanced acoustic design | Significant, quieter than conventional turbofans |

| Fuel Efficiency | Up to 25% better than previous engines | Up to 16% better than older models |

| Gear Mechanism | No gear; uses variable pitch fan blades | Reduction gearbox connecting fan and turbine |

| Fan Diameter | Approx. 140 inches (3.56 meters) | Typically around 81 inches (2.06 meters) |

| Bypass Ratio | Up to 15:1 | Typically around 12:1 |

| Thermal Efficiency | Enhanced with improved materials and design | Improved compared to conventional turbofans |

| Applications | Next-gen widebody airliners (e.g., Airbus A350 successor) | Narrowbody and regional jets (e.g., Airbus A320neo, Embraer E2) |

Introduction to Ultrafan and Geared Turbofan Technologies

Ultrafan and Geared Turbofan represent advanced jet engine technologies aimed at enhancing fuel efficiency and reducing emissions in commercial aviation. Ultrafan engines utilize composite fan blades and a variable-pitch fan to optimize thrust across flight conditions, while Geared Turbofan engines incorporate a gearbox to allow the fan and turbine to rotate at independent speeds, improving propulsion efficiency. Both technologies signify major innovations in engine design, targeting improved performance and lower environmental impact compared to conventional turbofan engines.

Evolution of Aircraft Engine Design

Ultrafan engines represent the next evolution in aircraft engine design by offering higher bypass ratios and improved fuel efficiency compared to traditional geared turbofans, which utilize a reduction gearbox to optimize fan speed. The advancement in composite materials and geared architecture enables Ultrafans to achieve significant reductions in CO2 emissions and noise levels while maintaining thrust performance. This shift towards ultrahigh bypass ratio engines marks a critical step in sustainable aviation, aligning with industry goals to enhance environmental performance without sacrificing power.

Key Engineering Differences: Ultrafan vs Geared Turbofan

Ultrafan engines employ a new, larger diameter fan and advanced composite materials to enhance efficiency and reduce weight, while geared turbofans use a planetary gear system to decouple fan and turbine speeds for optimized performance. The Ultrafan's architecture emphasizes higher bypass ratios and variable pitch fans to improve fuel burn and noise reduction, whereas geared turbofans rely on mechanical gearboxes to achieve similar goals with proven variable pitch technology. Understanding these engineering distinctions helps you appreciate advancements in propulsion that maximize thrust and lower emissions in modern aircraft engines.

Efficiency and Fuel Consumption Comparison

Ultrafan engines demonstrate superior fuel efficiency by integrating a larger fan diameter with advanced composite materials, reducing specific fuel consumption by up to 20% compared to traditional geared turbofans. Geared turbofan technology improves efficiency through a reduction gearbox that allows the fan and turbine to operate at optimal speeds, resulting in about 15% less fuel burn than conventional turbofans. However, Ultrafans achieve greater overall efficiency gains by combining higher bypass ratios and novel materials, which contribute to lower carbon emissions and operational costs.

Environmental Impact: Emissions and Noise Reduction

Ultrafan engines deliver significant environmental benefits by reducing fuel consumption and lowering CO2 emissions through advanced bypass ratios and efficient materials. Geared turbofan technology optimizes fan speed independent of the turbine, leading to quieter operation and reduced noise pollution near airports. Both technologies contribute to meeting stringent international regulations on emissions and noise, promoting sustainable aviation development.

Performance and Reliability Analysis

Ultrafan engines offer significant performance improvements over geared turbofans through higher bypass ratios and advanced materials, resulting in better fuel efficiency and lower emissions. Geared turbofans, while reliable and proven in commercial aviation, tend to have more mechanical complexity due to the reduction gearbox, potentially impacting long-term maintenance costs. Your choice between Ultrafan and geared turbofan technology should weigh the balance between enhanced fuel savings and the maturity of gearbox-driven reliability.

Cost Implications and Maintenance Requirements

Ultrafan engines offer lower maintenance costs due to advanced materials and modular designs that reduce parts wear compared to traditional geared turbofans, which often require more frequent inspections and overhauls. The initial investment in Ultrafan technology tends to be higher, but the long-term operational savings can offset this through improved fuel efficiency and reduced downtime. Your airline can benefit from Ultrafan's lifecycle cost advantages despite the upfront expense, making it a strategic choice for modern fleet management.

Future Prospects and Market Adoption

Ultrafan engines, featuring higher bypass ratios and advanced materials, promise greater fuel efficiency and reduced emissions, driving strong interest from leading aircraft manufacturers. Geared turbofans offer improved fuel economy and noise reduction through a specialized transmission system, positioning them as a competitive alternative in regional and short-haul markets. Your choice between these technologies depends on factors like operational efficiency goals and evolving regulations shaping aviation's future landscape.

Challenges and Opportunities in Implementation

Ultrafan engines face challenges including higher initial development costs and complexity in materials like composite fan blades, but offer opportunities for significant fuel efficiency gains and noise reduction compared to geared turbofans. Geared turbofans benefit from proven technology with existing manufacturing infrastructure, yet encounter limitations in scaling fan diameter and achieving next-level efficiency improvements. Implementation of Ultrafan technology presents a strategic opportunity for airlines aiming to reduce carbon emissions and operational costs, despite current certification and integration hurdles.

Conclusion: Which Engine Leads the Future of Aviation?

Ultrafan engines lead the future of aviation by offering superior fuel efficiency, lower emissions, and advanced materials compared to geared turbofan designs. Your choice for sustainable air travel aligns with Ultrafan technology's focus on higher bypass ratios and innovative architecture that maximize propulsion efficiency. Geared turbofans remain relevant for certain applications but cannot match the long-term environmental and economic benefits presented by Ultrafan engines.

Ultrafan vs Geared turbofan Infographic

libmatt.com

libmatt.com