The Sikorsky rotor features a distinctive fully articulated design with three or more blades, providing enhanced maneuverability and stability in various flight conditions. Eurocopter rotors typically use a rigid or semi-rigid system that offers simplicity and reduced maintenance, making your helicopter easier to operate and maintain.

Table of Comparison

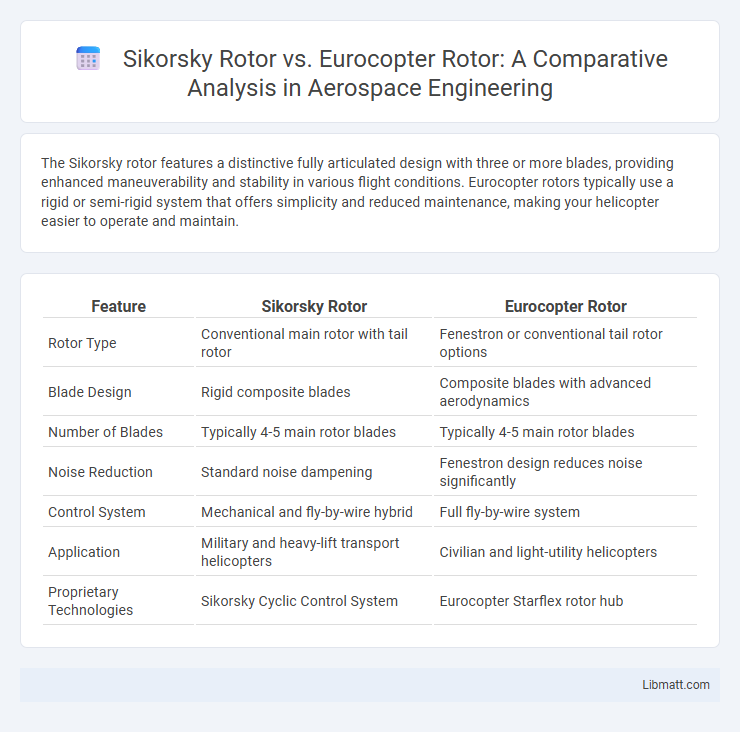

| Feature | Sikorsky Rotor | Eurocopter Rotor |

|---|---|---|

| Rotor Type | Conventional main rotor with tail rotor | Fenestron or conventional tail rotor options |

| Blade Design | Rigid composite blades | Composite blades with advanced aerodynamics |

| Number of Blades | Typically 4-5 main rotor blades | Typically 4-5 main rotor blades |

| Noise Reduction | Standard noise dampening | Fenestron design reduces noise significantly |

| Control System | Mechanical and fly-by-wire hybrid | Full fly-by-wire system |

| Application | Military and heavy-lift transport helicopters | Civilian and light-utility helicopters |

| Proprietary Technologies | Sikorsky Cyclic Control System | Eurocopter Starflex rotor hub |

Introduction to Helicopter Rotor Systems

Sikorsky rotor systems use a fully articulated rotor with multiple blades that provide enhanced maneuverability and stability, optimizing lift and control in various flight conditions. Eurocopter rotors often employ a rigid or hingeless design, which reduces mechanical complexity and maintenance requirements while improving aerodynamic efficiency. Both rotor types play crucial roles in their helicopters' performance, balancing responsiveness and reliability for diverse operational needs.

Overview of Sikorsky Rotor Design

Sikorsky rotor design features a unique fully articulated main rotor system allowing for enhanced maneuverability and stability, crucial for complex flight operations. Its distinctive swashplate mechanism and robust rotor blades optimize lift and reduce vibration, enhancing overall flight performance. You benefit from precise control and reliability in diverse aerospace applications when choosing Sikorsky's advanced rotor technology.

Overview of Eurocopter Rotor Design

Eurocopter rotors feature advanced composite blades with swept tips designed to reduce noise and enhance aerodynamic efficiency. The rotor system incorporates a bearingless hub that minimizes mechanical complexity and improves reliability compared to traditional articulated hubs. These design innovations contribute to superior maneuverability and lower vibration levels in Eurocopter helicopters relative to Sikorsky's conventional rotor configurations.

Key Technological Differences

Sikorsky rotors feature a unique rigid rotor system with elastomeric bearings, enabling enhanced maneuverability and reduced vibration, while Eurocopter (now Airbus Helicopters) typically employs articulated or bearingless rotors prioritizing smoother flight and lower maintenance. Sikorsky's designs often utilize advanced composite materials for rotor blades, improving strength-to-weight ratio and durability, compared to Eurocopter's emphasis on modular blade systems facilitating easier repairs and replacements. The Sikorsky rotors incorporate advanced active vibration control technologies, which contrast with Eurocopter's focus on aerodynamic efficiency through optimized blade geometry and rotor hub designs.

Aerodynamic Performance Comparison

Sikorsky rotors are designed with advanced bearingless technology that reduces vibration and improves lift efficiency, enhancing overall aerodynamic performance in various flight conditions. Eurocopter rotors feature a distinctive composite blade design enabling superior agility and reduced drag, which optimizes fuel consumption and handling. Your choice between these rotors should consider mission-specific aerodynamic demands, as Sikorsky excels in stability while Eurocopter offers greater maneuverability.

Maintenance and Durability Factors

Sikorsky rotor systems emphasize modular maintenance with easily replaceable components, reducing downtime and enhancing operational readiness for military applications. Eurocopter rotors, featuring composite materials, deliver increased corrosion resistance and lower maintenance cycles, improving long-term durability in civilian and rescue missions. Both manufacturers incorporate advanced blade monitoring technologies to predict wear, yet Sikorsky's use of articulated rotor designs contrasts with Eurocopter's rigid rotor systems, influencing maintenance complexity and fatigue life.

Noise and Vibration Characteristics

Sikorsky rotors utilize advanced blade design and active vibration control systems that significantly reduce noise emissions and minimize in-cabin vibrations. Eurocopter rotors feature tailored blade tip modifications and advanced composite materials, optimizing aerodynamic performance to lower acoustic signatures and vibration levels. Both designs emphasize noise reduction, but Sikorsky's active vibration control systems provide superior cabin comfort by dynamically counteracting rotor-induced vibrations.

Flight Stability and Control

Sikorsky rotors, featuring a rigid or semi-rigid rotor system with advanced vibration reduction technology, deliver exceptional flight stability and precise control, especially in challenging maneuvers and hover performance. Eurocopter rotors typically employ a bearingless main rotor design that enhances aerodynamic efficiency and reduces mechanical complexity, contributing to smoother control inputs and reduced pilot workload. Both rotor systems optimize flight stability through innovative blade articulation and advanced flight control systems, but Sikorsky's design emphasizes robust handling in adverse conditions, while Eurocopter focuses on agility and responsive control dynamics.

Operational Applications and Suitability

Sikorsky rotors, characterized by their rigid rotor system and advanced vibration control, excel in tactical military operations and heavy-lift missions, providing enhanced maneuverability and stability in demanding environments. Eurocopter rotors, featuring a hingeless and bearingless design, are optimized for civilian air transport and search-and-rescue missions, offering reduced maintenance requirements and smoother flight performance. Both rotor systems demonstrate high operational suitability, with Sikorsky favored for combat and heavy-duty applications, while Eurocopter is preferred for efficiency and versatility in civilian and paramilitary roles.

Future Innovations in Rotor Technology

Sikorsky rotor technology emphasizes active vibration control and morphing blade designs to enhance flight stability and reduce noise. Eurocopter, now Airbus Helicopters, advances in rotor systems center on bearingless main rotors and composite materials to improve durability and performance efficiency. Both companies prioritize integrating smart sensors and adaptive aerodynamics to revolutionize rotorcraft capabilities in future innovation.

Sikorsky rotor vs Eurocopter rotor Infographic

libmatt.com

libmatt.com