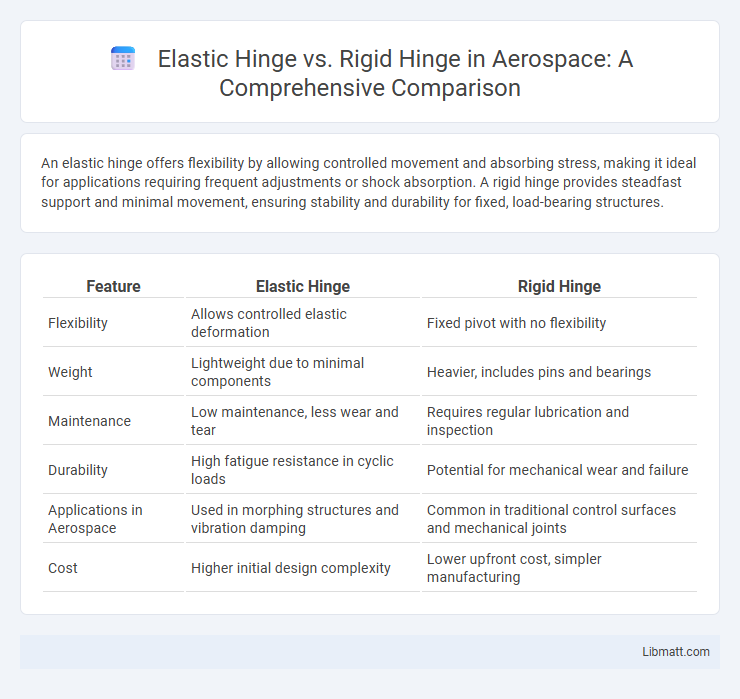

An elastic hinge offers flexibility by allowing controlled movement and absorbing stress, making it ideal for applications requiring frequent adjustments or shock absorption. A rigid hinge provides steadfast support and minimal movement, ensuring stability and durability for fixed, load-bearing structures.

Table of Comparison

| Feature | Elastic Hinge | Rigid Hinge |

|---|---|---|

| Flexibility | Allows controlled elastic deformation | Fixed pivot with no flexibility |

| Weight | Lightweight due to minimal components | Heavier, includes pins and bearings |

| Maintenance | Low maintenance, less wear and tear | Requires regular lubrication and inspection |

| Durability | High fatigue resistance in cyclic loads | Potential for mechanical wear and failure |

| Applications in Aerospace | Used in morphing structures and vibration damping | Common in traditional control surfaces and mechanical joints |

| Cost | Higher initial design complexity | Lower upfront cost, simpler manufacturing |

Introduction to Hinge Types

Elastic hinges offer flexibility and resilience, allowing movement with controlled resistance, ideal for applications requiring smooth, adjustable motion. Rigid hinges provide firm, unyielding support, ensuring stability and precise positioning in structures or devices without bending. Your choice between elastic and rigid hinges depends on whether dynamic movement or steady alignment is crucial for your specific project.

What is an Elastic Hinge?

An elastic hinge is a flexible mechanical joint that allows controlled rotation while storing and releasing energy through deformation of its material. Unlike rigid hinges, the elastic hinge does not have discrete pivot points but relies on the elasticity of the material to enable smooth, continuous movement. Your design benefits from elastic hinges include reduced wear and maintenance due to the absence of frictional contact typical in rigid hinges.

What is a Rigid Hinge?

A rigid hinge is a mechanical joint designed to maintain a fixed angle between two connected parts, allowing rotation around a single axis without any relative movement or flexibility in other directions. It provides structural stability and precise control in applications such as door mechanisms, robotic arms, and machinery components. Unlike elastic hinges, rigid hinges do not flex or absorb energy; they ensure firm and consistent alignment under load.

Key Differences: Elastic Hinge vs Rigid Hinge

Elastic hinges allow controlled flexing and absorb stress through their flexible material, making them ideal for applications requiring movement and vibration damping. Rigid hinges provide fixed rotational movement without flexibility, offering strong structural support in mechanical systems that demand precise, stable connections. Your choice depends on whether you prioritize flexibility and stress absorption or solid, stable joint performance.

Mechanical Behavior and Performance

Elastic hinges exhibit flexibility by allowing controlled rotational movement through material deformation, resulting in smooth motion with minimal backlash and wear. Rigid hinges provide fixed rotational axes with limited flexibility, offering higher load capacity and structural stability but often at the expense of increased friction and potential stress concentration. The choice between elastic and rigid hinges significantly impacts mechanical behavior, with elastic hinges excelling in precision applications requiring smooth, repeatable motion, while rigid hinges are preferred for heavy-duty loads demanding robust support.

Applications of Elastic Hinges

Elastic hinges are widely used in applications requiring smooth, flexible motion with built-in resilience, such as in wearable devices, robotics, and automotive systems where continuous bending without fatigue is critical. Their ability to store and release energy allows precise movement control and accommodates repeated cycles, making them ideal for hinges in foldable electronics and soft actuators. You benefit from enhanced durability and flexibility in designs requiring lightweight, compact, and maintenance-free hinge solutions.

Applications of Rigid Hinges

Rigid hinges are commonly used in heavy machinery, aerospace structures, and automotive assemblies where stable and precise angular positioning is critical. These hinges provide limited or no flexibility, ensuring components maintain fixed orientations under high loads and repeated stress cycles. Your equipment benefits from enhanced durability and consistent performance when incorporating rigid hinges in load-bearing or structural applications.

Advantages and Drawbacks of Each Hinge

Elastic hinges provide flexibility and durability, allowing for smooth motion and vibration absorption, which benefits applications requiring repeated bending or slight movement. Rigid hinges offer strong, stable support with minimal play, making them ideal for applications demanding solid, fixed connections and precise alignment. Your choice depends on the need for flexibility versus stability, as elastic hinges may wear out faster under heavy loads, while rigid hinges can restrict movement and cause stress concentration.

Design Considerations and Material Selection

Elastic hinges require flexible materials such as thermoplastic elastomers or compliant metals to enable repeated bending without fatigue, emphasizing durability and flexibility in design. Rigid hinges demand stronger materials like steel or reinforced polymers to provide fixed pivot points capable of bearing significant loads, prioritizing stability and structural integrity. Design considerations for elastic hinges focus on maximizing elasticity and minimizing stress concentration, while rigid hinges emphasize precise alignment and robust fastening methods.

Choosing the Right Hinge for Your Project

Selecting between an elastic hinge and a rigid hinge depends on your project's flexibility and durability requirements. Elastic hinges offer flexibility, absorbing stress and allowing movement, making them ideal for applications needing repeated bending, while rigid hinges provide firm, stable support for static or load-bearing structures. Understanding these performance characteristics enables you to choose the right hinge that optimizes functionality and longevity in your design.

Elastic Hinge vs Rigid Hinge Infographic

libmatt.com

libmatt.com