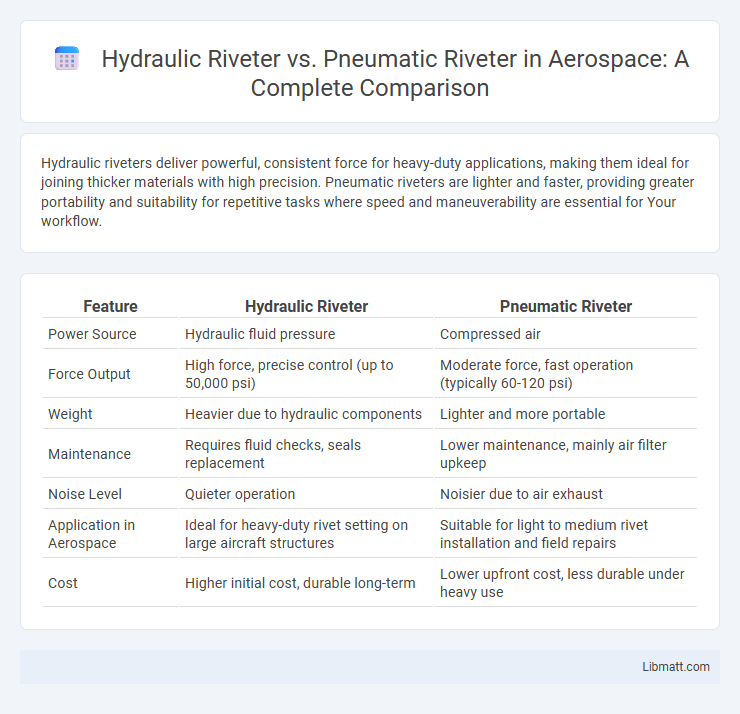

Hydraulic riveters deliver powerful, consistent force for heavy-duty applications, making them ideal for joining thicker materials with high precision. Pneumatic riveters are lighter and faster, providing greater portability and suitability for repetitive tasks where speed and maneuverability are essential for Your workflow.

Table of Comparison

| Feature | Hydraulic Riveter | Pneumatic Riveter |

|---|---|---|

| Power Source | Hydraulic fluid pressure | Compressed air |

| Force Output | High force, precise control (up to 50,000 psi) | Moderate force, fast operation (typically 60-120 psi) |

| Weight | Heavier due to hydraulic components | Lighter and more portable |

| Maintenance | Requires fluid checks, seals replacement | Lower maintenance, mainly air filter upkeep |

| Noise Level | Quieter operation | Noisier due to air exhaust |

| Application in Aerospace | Ideal for heavy-duty rivet setting on large aircraft structures | Suitable for light to medium rivet installation and field repairs |

| Cost | Higher initial cost, durable long-term | Lower upfront cost, less durable under heavy use |

Introduction to Hydraulic and Pneumatic Riveters

Hydraulic riveters utilize fluid pressure to generate high force, enabling the installation of heavy-duty rivets in metal fabrication and construction applications. Pneumatic riveters operate using compressed air to drive rivet fasteners efficiently, making them ideal for lighter, repetitive fastening tasks in automotive and manufacturing industries. Both tools enhance assembly productivity by providing controlled, consistent riveting power suited to various material thicknesses and production demands.

How Hydraulic Riveters Work

Hydraulic riveters use fluid pressure to generate a strong, consistent force that deforms and securely fastens rivets, providing high precision and control in heavy-duty applications. The hydraulic system operates through a reservoir, pump, and cylinder, allowing smooth and powerful piston movement to compress the rivet shank efficiently. This method enables riveters to handle larger rivets and thicker materials with less operator effort compared to pneumatic riveters, making them ideal for industrial manufacturing and construction.

How Pneumatic Riveters Work

Pneumatic riveters operate by using compressed air to power a piston that drives the rivet through materials, creating a secure fastening. The air pressure generates rapid, repetitive impacts, allowing for efficient and consistent riveting in industrial applications. This mechanism offers greater speed and reduced operator fatigue compared to manual riveting methods.

Key Differences Between Hydraulic and Pneumatic Riveters

Hydraulic riveters generate higher force through fluid pressure, making them ideal for heavy-duty applications requiring high precision and consistent power, while pneumatic riveters operate using compressed air, offering faster operation and lighter weight for moderate-duty tasks. Hydraulic systems provide greater control and reduced operator fatigue due to smoother power delivery, whereas pneumatic riveters excel in speed and portability but may deliver less consistent force. Maintenance requirements vary, with hydraulic riveters needing periodic fluid checks and seals replacement, and pneumatic riveters requiring air supply regulation and lubrication.

Performance Comparison: Hydraulic vs Pneumatic Riveting

Hydraulic riveters deliver higher force and precise control, making them ideal for heavy-duty applications and materials requiring consistent, strong rivet joints. Pneumatic riveters offer faster operation and greater portability but may produce less consistent force, suitable for lighter tasks and high-volume production. Your choice depends on balancing the need for power and precision against speed and convenience in riveting performance.

Application Suitability: Which Riveter for Which Task?

Hydraulic riveters deliver high force and precise control, making them ideal for heavy-duty applications such as structural steelwork and automotive assembly where consistent, strong joints are critical. Pneumatic riveters excel in speed and portability, suited for light to medium tasks like aircraft maintenance and manufacturing lines requiring rapid, repetitive riveting. Your choice depends on the task's scale and precision needs, with hydraulic models favored for demanding jobs and pneumatic tools preferred for efficiency in less intense settings.

Advantages of Hydraulic Riveters

Hydraulic riveters offer superior force control and consistent pressure, making them ideal for heavy-duty applications requiring precise and strong fastening. These tools deliver increased power with less effort, reducing operator fatigue and improving productivity on large-scale projects. Your work benefits from the enhanced durability and efficiency of hydraulic riveters, especially when handling thicker materials or repetitive tasks.

Advantages of Pneumatic Riveters

Pneumatic riveters offer superior power-to-weight ratio, enabling efficient operation with reduced operator fatigue in industrial applications. Their fast cycling speed enhances productivity, making them ideal for repetitive tasks in automotive and aerospace manufacturing. The reliance on compressed air minimizes heat generation, ensuring safer handling and longer tool lifespan compared to hydraulic riveters.

Cost and Maintenance Considerations

Hydraulic riveters generally have higher upfront costs but offer lower long-term maintenance expenses due to their robust construction and fewer moving parts. Pneumatic riveters typically cost less initially but require more frequent servicing and air compressor maintenance, increasing overall operational costs. Your choice should factor in the total cost of ownership, balancing initial investment with maintenance frequency and durability.

Choosing the Right Riveter for Your Project

Hydraulic riveters deliver high force suitable for heavy-duty applications and thick materials, providing consistent pressure for durable rivets, while pneumatic riveters offer faster operation and are ideal for medium to light tasks requiring speed and portability. Selecting the right riveter depends on project specifics such as material thickness, rivet size, and production volume, with hydraulic models excelling in industrial manufacturing and pneumatic ones favored in maintenance or assembly lines. Assessing factors like tool weight, air compressor availability, and precision requirements ensures optimal performance and efficiency in riveting tasks.

Hydraulic riveter vs Pneumatic riveter Infographic

libmatt.com

libmatt.com