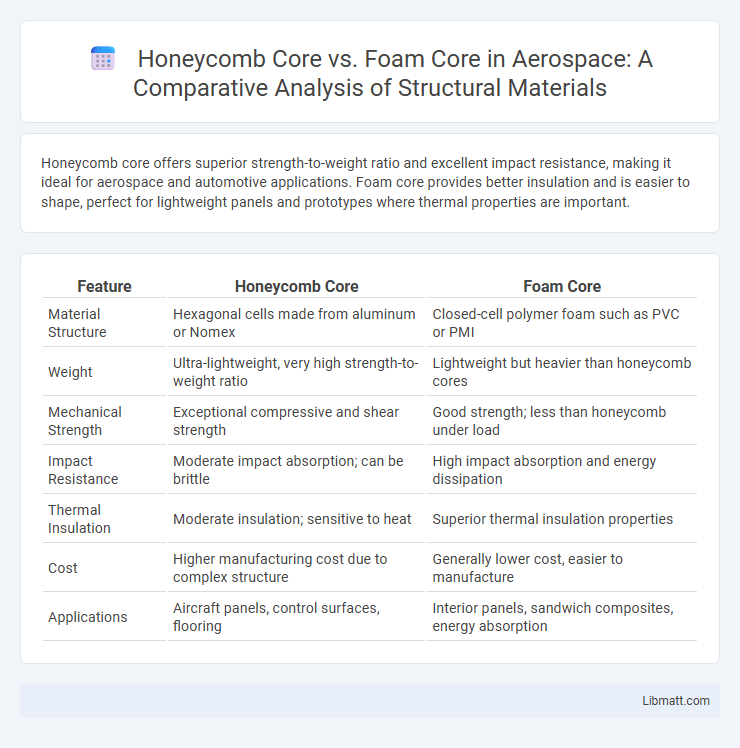

Honeycomb core offers superior strength-to-weight ratio and excellent impact resistance, making it ideal for aerospace and automotive applications. Foam core provides better insulation and is easier to shape, perfect for lightweight panels and prototypes where thermal properties are important.

Table of Comparison

| Feature | Honeycomb Core | Foam Core |

|---|---|---|

| Material Structure | Hexagonal cells made from aluminum or Nomex | Closed-cell polymer foam such as PVC or PMI |

| Weight | Ultra-lightweight, very high strength-to-weight ratio | Lightweight but heavier than honeycomb cores |

| Mechanical Strength | Exceptional compressive and shear strength | Good strength; less than honeycomb under load |

| Impact Resistance | Moderate impact absorption; can be brittle | High impact absorption and energy dissipation |

| Thermal Insulation | Moderate insulation; sensitive to heat | Superior thermal insulation properties |

| Cost | Higher manufacturing cost due to complex structure | Generally lower cost, easier to manufacture |

| Applications | Aircraft panels, control surfaces, flooring | Interior panels, sandwich composites, energy absorption |

Introduction to Core Materials in Engineering

Honeycomb core materials offer exceptional strength-to-weight ratios by utilizing a hexagonal cell structure made from aluminum or Nomex, widely favored in aerospace and automotive engineering for structural efficiency. Foam core materials, typically composed of polyurethane, polystyrene, or PVC, provide excellent thermal insulation and impact resistance, making them ideal for marine and composite panel applications. Both core types enhance sandwich panel performance by distributing loads and improving stiffness while minimizing overall weight in advanced engineering designs.

Understanding Honeycomb Core Structure

Honeycomb core structure consists of hexagonal cells made from materials like aluminum, Nomex, or paper, providing exceptional strength-to-weight ratio and rigidity. This design efficiently distributes stress and resists compression, making it ideal for aerospace, marine, and automotive applications where lightweight durability is crucial. Understanding how honeycomb cores optimize your product's structural integrity helps you choose the best core material for performance and longevity.

Exploring Foam Core Composition

Foam core consists of a lightweight, rigid polyurethane or polystyrene foam sandwiched between two outer layers, typically made of paper, plastic, or metal, which offers excellent thermal insulation and impact resistance. This composition provides superior cushioning and sound absorption compared to honeycomb core materials, making it ideal for applications requiring lightweight durability and energy dampening. Your choice between foam core and honeycomb core should consider factors such as weight constraints, structural strength, and insulation needs.

Weight and Density Comparison

Honeycomb core structures offer superior strength-to-weight ratios with densities typically ranging from 30 to 100 kg/m3, making them significantly lighter than foam cores. Foam cores, such as PVC or polyurethane foams, exhibit higher densities between 50 and 200 kg/m3, resulting in increased overall weight for equivalent volumes. The low density and high strength of honeycomb cores contribute to weight savings in aerospace and marine applications, outperforming foam cores in weight-sensitive designs.

Mechanical Strength and Performance

Honeycomb cores provide superior mechanical strength and stiffness due to their geometric structure, which efficiently distributes loads and resists bending and compression. Foam cores offer lighter weight and excellent energy absorption but generally deliver lower strength and rigidity compared to honeycomb, making them suitable for applications requiring impact damping rather than high structural loads. Your choice between honeycomb and foam cores should consider specific performance needs, balancing durability and weight constraints.

Insulation and Thermal Properties

Honeycomb core structures offer superior insulation with high thermal resistance due to their air-filled cells, effectively reducing heat transfer compared to foam cores. Foam cores provide good thermal insulation as well, primarily due to their closed-cell structure, but typically exhibit lower thermal resistance than honeycomb cores of similar thickness. The choice between honeycomb and foam cores impacts energy efficiency in applications such as aerospace, automotive, and construction, where maintaining consistent temperature and minimizing heat loss are critical.

Applications in Aerospace and Construction

Honeycomb core offers superior strength-to-weight ratio and impact resistance, making it ideal for aerospace structures like aircraft wings and fuselage panels where durability and lightweight materials are critical. Foam core provides excellent thermal insulation and sound absorption, favored in construction for sandwich panels and architectural cladding to enhance energy efficiency and comfort. Your choice between honeycomb and foam cores depends on whether structural performance or insulation properties are the priority in aerospace or building applications.

Durability and Environmental Resistance

Honeycomb core materials exhibit superior durability and environmental resistance due to their rigid structure, which effectively distributes stress and resists compression, making them ideal for aerospace and marine applications. Foam core, while lightweight, tends to absorb moisture and can degrade faster under UV exposure and harsh environmental conditions, limiting its use in long-term outdoor applications. The closed-cell structure of high-density foam cores can improve resistance but generally still falls short of the mechanical robustness and environmental stability offered by honeycomb cores.

Cost Efficiency and Manufacturing Considerations

Honeycomb core offers superior cost efficiency for large-scale production due to its low material usage combined with high strength-to-weight ratio, resulting in long-term savings on materials and transportation. Foam core, while typically cheaper upfront and easier to machine, may incur higher costs in applications requiring durability and strength, as it often necessitates thicker layers or reinforcements. Your choice between honeycomb core and foam core should consider manufacturing complexity, with honeycomb requiring precise bonding and tooling but delivering better performance in high-stress environments.

Choosing the Right Core Material for Your Project

Honeycomb cores offer superior strength-to-weight ratio, making them ideal for aerospace and marine applications where lightweight durability is critical. Foam cores, providing excellent thermal insulation and ease of machining, suit projects requiring impact absorption and cost-efficiency, such as automotive and construction panels. Selecting the right core material depends on factors like load-bearing requirements, environmental conditions, and budget constraints for optimized performance.

Honeycomb core vs Foam core Infographic

libmatt.com

libmatt.com