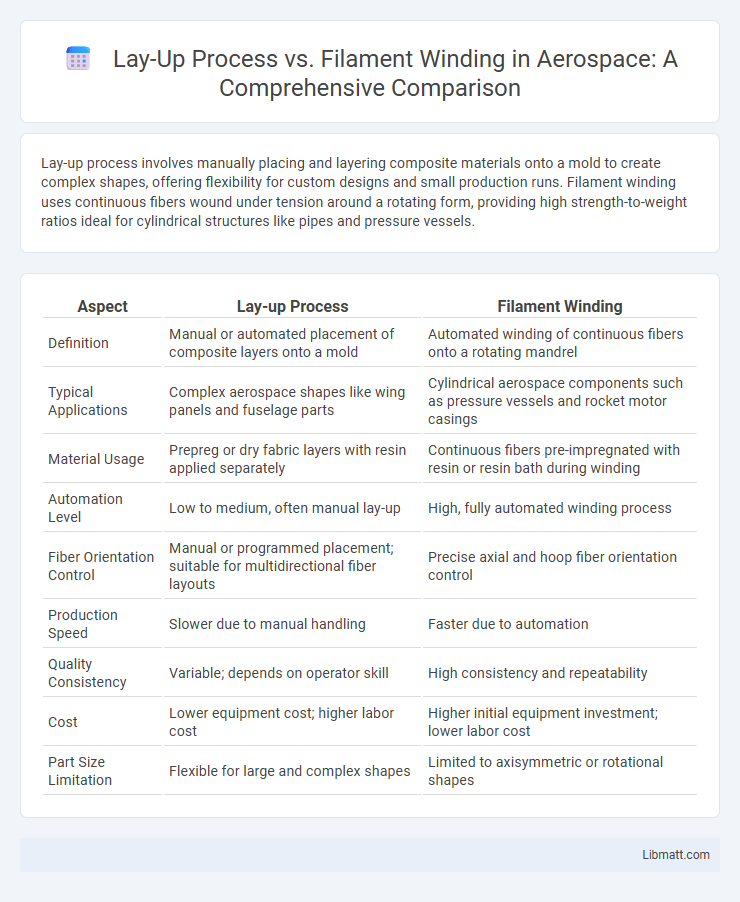

Lay-up process involves manually placing and layering composite materials onto a mold to create complex shapes, offering flexibility for custom designs and small production runs. Filament winding uses continuous fibers wound under tension around a rotating form, providing high strength-to-weight ratios ideal for cylindrical structures like pipes and pressure vessels.

Table of Comparison

| Aspect | Lay-up Process | Filament Winding |

|---|---|---|

| Definition | Manual or automated placement of composite layers onto a mold | Automated winding of continuous fibers onto a rotating mandrel |

| Typical Applications | Complex aerospace shapes like wing panels and fuselage parts | Cylindrical aerospace components such as pressure vessels and rocket motor casings |

| Material Usage | Prepreg or dry fabric layers with resin applied separately | Continuous fibers pre-impregnated with resin or resin bath during winding |

| Automation Level | Low to medium, often manual lay-up | High, fully automated winding process |

| Fiber Orientation Control | Manual or programmed placement; suitable for multidirectional fiber layouts | Precise axial and hoop fiber orientation control |

| Production Speed | Slower due to manual handling | Faster due to automation |

| Quality Consistency | Variable; depends on operator skill | High consistency and repeatability |

| Cost | Lower equipment cost; higher labor cost | Higher initial equipment investment; lower labor cost |

| Part Size Limitation | Flexible for large and complex shapes | Limited to axisymmetric or rotational shapes |

Introduction to Composite Manufacturing Processes

Composite manufacturing processes like the lay-up and filament winding techniques play crucial roles in producing high-strength, lightweight materials tailored for various industries. Lay-up involves manually placing fiber reinforcements in molds with resin, ideal for large, complex shapes, while filament winding uses automated fiber winding around molds for creating cylindrical structures with precise fiber orientation. Understanding these methods enhances your ability to select the most efficient process for specific composite applications, balancing cost, performance, and design requirements.

Overview of the Lay-up Process

The lay-up process involves manually placing and layering composite materials, such as fiberglass or carbon fiber, onto a mold to create strong, lightweight structures. This technique allows for precise control over fiber orientation and is commonly used in manufacturing complex shapes for aerospace, marine, and automotive components. Compared to filament winding, lay-up offers greater flexibility in design but tends to be more labor-intensive and less automated.

Fundamentals of Filament Winding

Filament winding is a manufacturing process that involves winding continuous fiber reinforcements, such as carbon or glass fibers, under tension onto a rotating mandrel in precise patterns to create high-strength composite structures. Unlike the lay-up process, which manually places fiber layers, filament winding achieves superior fiber alignment and resin distribution, resulting in enhanced mechanical properties and repeatability. Your choice between these methods depends on the desired strength, structural complexity, and production volume of the composite part.

Key Materials Used in Both Processes

The lay-up process primarily uses composite materials like fiberglass or carbon fiber sheets combined with resin matrices such as epoxy or polyester. Filament winding employs continuous fiber reinforcements, typically carbon, glass, or aramid fibers, impregnated with thermosetting resins like epoxy or vinyl ester. Both processes rely on high-strength fibers and resin systems optimized for structural performance and durability.

Step-by-Step Lay-up Process Explained

The lay-up process involves carefully placing resin-impregnated fibers or dry fabrics layer by layer onto a mold, followed by curing under controlled temperature and pressure to form a composite part. Each ply orientation is strategically aligned to optimize mechanical properties, with intermediate trimming and inspection to ensure quality. Unlike filament winding, which uses continuous fiber placement around a rotating mandrel, lay-up offers greater design flexibility for complex shapes but requires meticulous manual or automated layering.

Filament Winding Procedure Detailed

Filament winding procedure involves the continuous winding of resin-impregnated fibers onto a rotating mandrel, precisely controlled to achieve optimal fiber orientation and layer thickness. This automated process ensures high strength-to-weight ratios in composite structures, suitable for pressure vessels and pipes. Compared to the manual lay-up process, filament winding offers superior uniformity, repeatability, and reduced material waste.

Comparative Advantages: Lay-up vs Filament Winding

The lay-up process offers superior design flexibility and customization for complex geometries, making it ideal for prototypes and low-volume production. Filament winding excels in producing high-strength, uniform cylindrical structures with enhanced mechanical properties and faster automated production. Your choice depends on whether you prioritize customization and manual precision (lay-up) or efficiency and structural consistency (filament winding).

Common Applications for Each Process

Lay-up process is commonly used in manufacturing large, complex-shaped composite parts such as boat hulls, automotive body panels, and wind turbine blades due to its versatility and ability to produce detailed designs. Filament winding is typically applied in creating high-strength, cylindrical structures like pressure vessels, pipelines, and aerospace components, where precise fiber placement and uniform strength are critical. Both processes serve specific industry needs, with lay-up favored for intricate shapes and filament winding preferred for optimized fiber orientation in rotationally symmetric parts.

Cost and Efficiency Considerations

Lay-up process typically incurs higher labor costs due to its manual nature, leading to longer production times and reduced efficiency for large-scale manufacturing. Filament winding offers cost advantages through automation, enabling faster production rates and consistent quality, which enhances overall operational efficiency. The choice between these methods depends on production volume and budget, where filament winding excels in high-volume, cost-effective fabrication of cylindrical composite structures.

Choosing the Right Process for Your Project

Choosing the right process for your project depends on factors such as part complexity, production volume, and material properties. Lay-up process offers greater flexibility for intricate shapes and lower volume runs, while filament winding excels in producing strong, consistent cylindrical structures at higher volumes. Your decision should consider project requirements for strength, precision, and cost efficiency to optimize manufacturing outcomes.

Lay-up process vs Filament winding Infographic

libmatt.com

libmatt.com