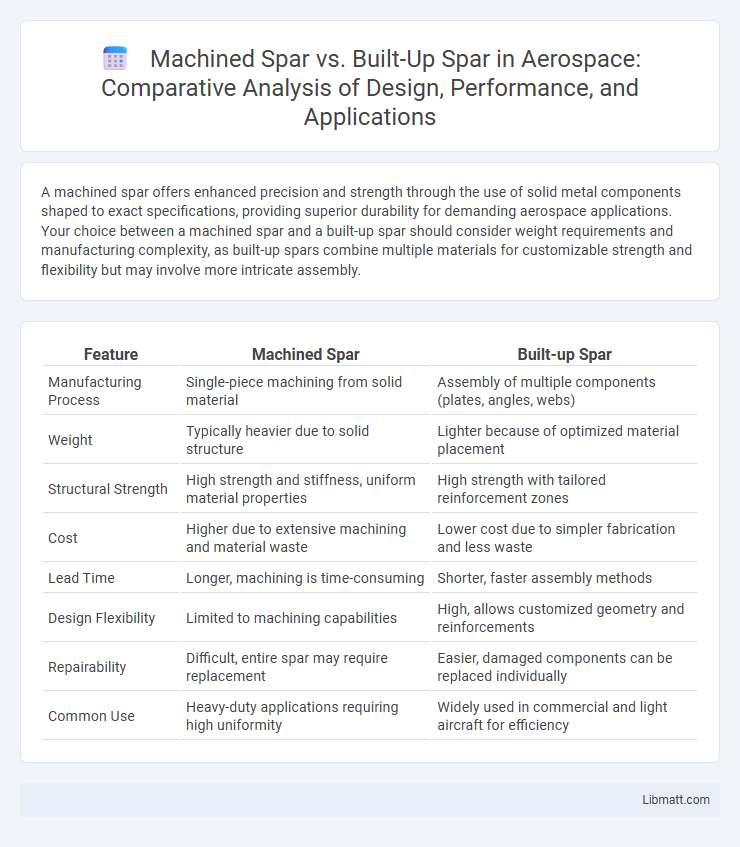

A machined spar offers enhanced precision and strength through the use of solid metal components shaped to exact specifications, providing superior durability for demanding aerospace applications. Your choice between a machined spar and a built-up spar should consider weight requirements and manufacturing complexity, as built-up spars combine multiple materials for customizable strength and flexibility but may involve more intricate assembly.

Table of Comparison

| Feature | Machined Spar | Built-up Spar |

|---|---|---|

| Manufacturing Process | Single-piece machining from solid material | Assembly of multiple components (plates, angles, webs) |

| Weight | Typically heavier due to solid structure | Lighter because of optimized material placement |

| Structural Strength | High strength and stiffness, uniform material properties | High strength with tailored reinforcement zones |

| Cost | Higher due to extensive machining and material waste | Lower cost due to simpler fabrication and less waste |

| Lead Time | Longer, machining is time-consuming | Shorter, faster assembly methods |

| Design Flexibility | Limited to machining capabilities | High, allows customized geometry and reinforcements |

| Repairability | Difficult, entire spar may require replacement | Easier, damaged components can be replaced individually |

| Common Use | Heavy-duty applications requiring high uniformity | Widely used in commercial and light aircraft for efficiency |

Introduction to Aircraft Spars

Aircraft spars are the main structural components running spanwise in the wings, critical for load-bearing and overall wing integrity. Machined spars are crafted from a single piece of metal, offering high strength-to-weight ratios and precision, while built-up spars consist of multiple elements assembled together for design flexibility and easier repairs. Your choice between these spar types impacts aircraft performance, maintenance, and manufacturing costs based on mission requirements and engineering constraints.

Understanding Machined Spars

Machined spars are precision-cut from a solid piece of high-grade aluminum or composite material, ensuring consistent strength and reduced weight compared to built-up spars, which are assembled from multiple components. This manufacturing approach improves the structural integrity and fatigue resistance of your aircraft wing, leading to enhanced performance and safety. Understanding machined spars helps you appreciate their role in delivering superior load distribution and streamlined maintenance.

Overview of Built-up Spars

Built-up spars are structural components in aerospace and civil engineering composed of multiple segments joined together, typically using rivets, bolts, or welding, to achieve greater strength and stiffness compared to a single-piece machined spar. These spars allow for customization in shape and material distribution, enhancing load-bearing capacity and weight efficiency in wing or beam construction. Their modular design facilitates easier repairs and modifications, making them advantageous in large-scale or complex structural applications.

Material Selection for Spar Construction

Material selection for machined spars typically involves high-strength aluminum alloys and titanium, valued for their superior strength-to-weight ratio and precision in machining processes. Built-up spars often utilize composite materials like carbon fiber or multiple metal sections riveted together, allowing for tailored mechanical properties and easier repairability. Choosing between machined and built-up spars depends on factors such as load requirements, manufacturing capabilities, and desired weight savings.

Manufacturing Processes Compared

Machined spars are manufactured from a single solid piece of metal or composite, employing CNC machining for precision shaping and reduced weight, resulting in consistent structural integrity and enhanced aerodynamic efficiency. Built-up spars consist of multiple components such as webs, flanges, and stiffeners that are fabricated separately and then riveted, bolted, or welded together, offering design flexibility and ease of repair but potentially increasing weight and complexity. The choice between machined and built-up spars depends on factors like load requirements, production volume, and maintenance considerations, influencing overall aircraft performance and manufacturing costs.

Weight and Structural Performance

Machined spars offer superior weight efficiency due to their single-piece construction, reducing the need for multiple fasteners and joints. Built-up spars, assembled from separate components, provide enhanced structural flexibility and easier repair but typically add weight because of overlapping materials and additional hardware. You can achieve optimal aircraft performance by balancing the lightweight advantage of machined spars with the customizable strength of built-up spars based on your design requirements.

Cost Analysis: Machined vs Built-up

Machined spars typically demand higher initial manufacturing costs due to precision CNC machining and raw material wastage, while built-up spars offer cost efficiency through simpler fabrication using multiple components like aluminum sheets and extrusions. Your choice affects labor expenses as built-up spars require more assembly time and skilled labor, potentially increasing overall costs despite lower material costs. In long-term analysis, machined spars often result in reduced maintenance and replacement costs owing to superior structural integrity and uniformity.

Maintenance and Repair Considerations

Machined spars offer superior precision and uniform stress distribution, reducing the frequency of maintenance checks compared to built-up spars, which consist of multiple components prone to loosening or corrosion. Repairing machined spars typically involves machining processes that require specialized equipment and expertise, while built-up spars allow for simpler, localized repairs by replacing individual elements, minimizing downtime. The choice between machined and built-up spars significantly impacts life-cycle maintenance costs and the complexity of repair procedures in aerospace and structural applications.

Applications in Modern Aircraft Design

Machined spars are favored in modern aircraft design for their precision, strength-to-weight ratio, and ability to integrate complex geometries, making them ideal for high-performance commercial and military jets. Built-up spars remain prevalent in general aviation and older aircraft models due to their ease of repair and lower manufacturing costs. Advanced composite materials are increasingly used with both spar types to optimize structural efficiency and reduce overall airframe weight.

Future Trends in Spar Technology

Machined spars, crafted from solid aluminum billets, offer high strength-to-weight ratios and precise tolerances, while built-up spars, assembled from multiple components, enable design flexibility and ease of repair. Future trends in spar technology emphasize the integration of advanced composites and automated manufacturing processes to reduce weight and improve durability. Innovations in additive manufacturing and smart materials are expected to further enhance spar performance, enabling adaptive load-bearing capabilities and real-time structural health monitoring.

Machined Spar vs Built-up Spar Infographic

libmatt.com

libmatt.com