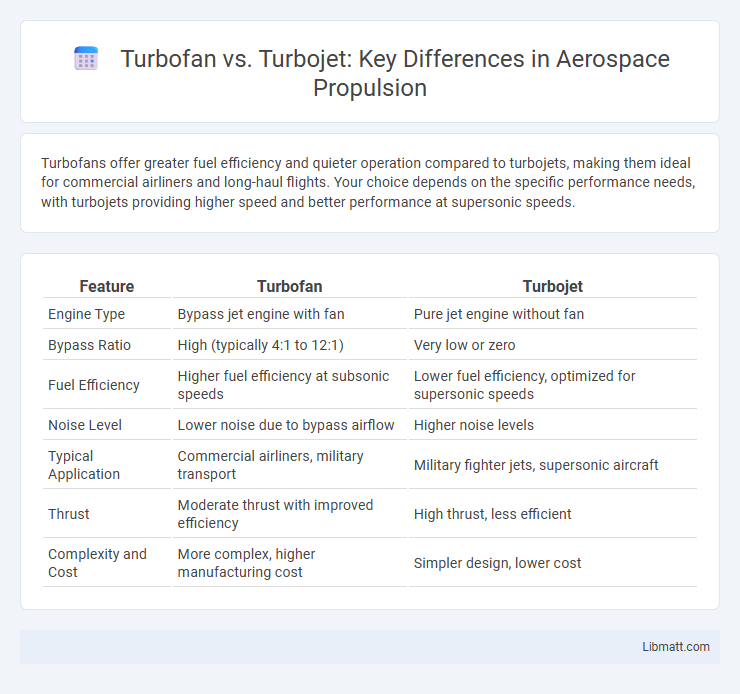

Turbofans offer greater fuel efficiency and quieter operation compared to turbojets, making them ideal for commercial airliners and long-haul flights. Your choice depends on the specific performance needs, with turbojets providing higher speed and better performance at supersonic speeds.

Table of Comparison

| Feature | Turbofan | Turbojet |

|---|---|---|

| Engine Type | Bypass jet engine with fan | Pure jet engine without fan |

| Bypass Ratio | High (typically 4:1 to 12:1) | Very low or zero |

| Fuel Efficiency | Higher fuel efficiency at subsonic speeds | Lower fuel efficiency, optimized for supersonic speeds |

| Noise Level | Lower noise due to bypass airflow | Higher noise levels |

| Typical Application | Commercial airliners, military transport | Military fighter jets, supersonic aircraft |

| Thrust | Moderate thrust with improved efficiency | High thrust, less efficient |

| Complexity and Cost | More complex, higher manufacturing cost | Simpler design, lower cost |

Introduction to Turbofan and Turbojet Engines

Turbofan engines feature a large fan that generates additional thrust by accelerating air around the engine core, improving fuel efficiency and reducing noise compared to turbojets. Turbojet engines produce thrust solely from high-speed exhaust gases generated by combustion, making them simpler but less fuel-efficient at subsonic speeds. Turbofans dominate commercial aviation due to their balance of performance and economy, while turbojets are preferred in military and supersonic aircraft for their high-speed capabilities.

How Turbofan Engines Work

Turbofan engines operate by drawing air into a large fan at the front, where most of the air bypasses the combustion chamber, generating thrust through a high-volume, low-velocity airflow. The core air undergoes compression, combustion, and expansion, driving the turbine that powers the fan and compressor stages, enhancing fuel efficiency and reducing noise compared to turbojets. This bypass air flow is fundamental to the turbofan's performance, allowing it to deliver higher thrust with less fuel consumption on commercial and military aircraft.

How Turbojet Engines Operate

Turbojet engines operate by compressing incoming air through multiple compressor stages, mixing it with fuel in the combustion chamber, and igniting the mixture to produce high-velocity exhaust gases. These exhaust gases pass through a turbine that powers the compressor before being expelled at high speed to generate thrust. The continuous flow and high-speed jet expelled create propulsion, making turbojets efficient for high-speed, high-altitude flight.

Key Differences Between Turbofan and Turbojet

Turbofan engines feature a large fan at the front that generates additional thrust by bypassing air around the engine core, resulting in higher fuel efficiency and quieter operation compared to turbojets, which rely solely on high-velocity exhaust gases for thrust. Turbojets produce greater maximum speeds and perform better at high altitudes, ideal for supersonic flight, but their higher fuel consumption and noise levels limit their use in commercial aviation. The bypass ratio, thrust generation method, fuel efficiency, noise levels, and typical applications represent the primary differences distinguishing turbofan and turbojet engines.

Performance Comparison: Speed and Efficiency

Turbofans deliver higher efficiency at subsonic speeds by utilizing a larger bypass ratio, significantly improving fuel consumption compared to turbojets. Turbojets excel in achieving higher maximum speeds, often used in supersonic applications due to their streamlined design and lower bypass airflow. The performance trade-off positions turbofans as optimal for commercial aviation with superior thrust-specific fuel consumption, while turbojets remain preferable for military jets demanding greater speed and altitude capabilities.

Fuel Consumption and Environmental Impact

Turbofans offer significantly lower fuel consumption compared to turbojets by utilizing a larger bypass ratio, which increases thrust efficiency and reduces specific fuel burn. This improved fuel efficiency leads to a decrease in carbon dioxide (CO2) emissions, making turbofans more environmentally friendly for commercial aviation. Turbojets, while producing higher speeds, typically generate greater noise pollution and emit higher levels of nitrogen oxides (NOx), contributing to environmental concerns and stricter regulatory limitations.

Applications in Commercial Aviation

Turbofan engines dominate commercial aviation due to their superior fuel efficiency and quieter operation compared to turbojets, making them ideal for passenger aircraft. Turbojets, with their higher exhaust velocity, find limited use in niche applications requiring high speed but are largely replaced by turbofans in modern airliners. Your choice of aircraft engine impacts operational costs and environmental compliance, with turbofans offering significant advantages in these areas.

Use in Military and High-Speed Aircraft

Turbojets deliver superior performance at extremely high speeds and altitudes, making them suitable for supersonic military aircraft like fighter jets due to their high thrust-to-weight ratio. Turbofans, especially low-bypass variants, offer better fuel efficiency and thrust at subsonic speeds, which is ideal for military transport planes and some tactical fighters requiring extended range and loiter time. Your choice between turbofan and turbojet engines depends on mission profiles and speed requirements, balancing raw speed with operational endurance.

Maintenance and Cost Considerations

Turbofans typically incur lower maintenance costs due to their simpler bypass design and slower turbine speeds, resulting in longer component life and reduced wear compared to turbojets. Turbojets, while offering higher thrust-to-weight ratios, demand more frequent inspections and overhauls because of their higher operating temperatures and stress levels. When evaluating engine options, your choice impacts long-term operational expenses, with turbofans generally providing better cost efficiency for commercial and fuel-sensitive applications.

Future Trends in Jet Engine Technology

Future trends in jet engine technology emphasize increased fuel efficiency and reduced emissions, with turbofans leading advancements due to their high bypass ratios and noise reduction capabilities. Emerging developments include geared turbofans and open rotor designs, which aim to optimize thrust while minimizing environmental impact. Turbojets, primarily associated with supersonic and military aircraft, face limitations in fuel efficiency, making turbofan innovations more prominent in commercial aviation's sustainable future.

Turbofan vs Turbojet Infographic

libmatt.com

libmatt.com