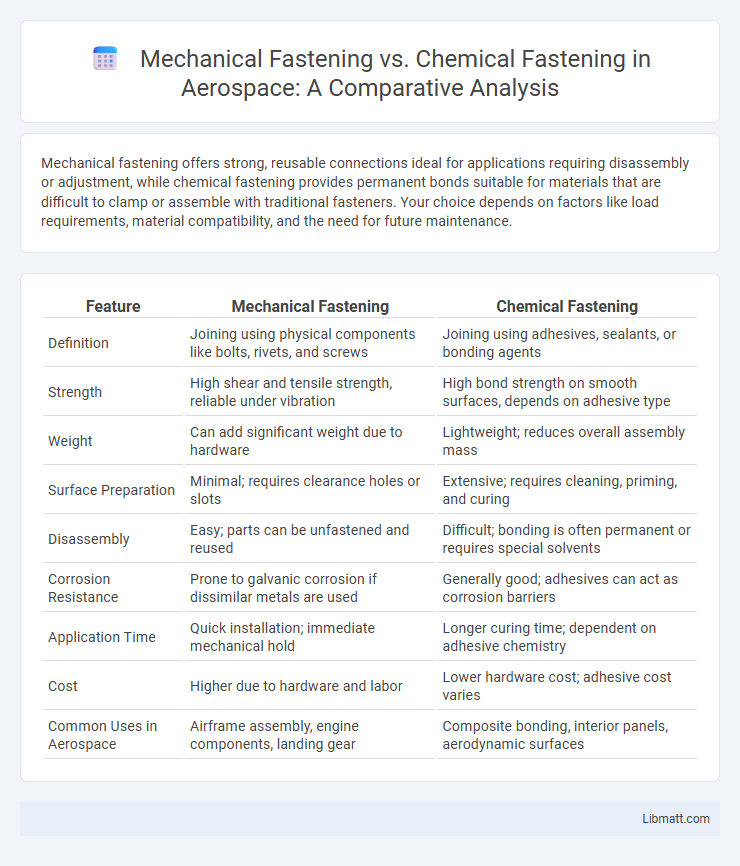

Mechanical fastening offers strong, reusable connections ideal for applications requiring disassembly or adjustment, while chemical fastening provides permanent bonds suitable for materials that are difficult to clamp or assemble with traditional fasteners. Your choice depends on factors like load requirements, material compatibility, and the need for future maintenance.

Table of Comparison

| Feature | Mechanical Fastening | Chemical Fastening |

|---|---|---|

| Definition | Joining using physical components like bolts, rivets, and screws | Joining using adhesives, sealants, or bonding agents |

| Strength | High shear and tensile strength, reliable under vibration | High bond strength on smooth surfaces, depends on adhesive type |

| Weight | Can add significant weight due to hardware | Lightweight; reduces overall assembly mass |

| Surface Preparation | Minimal; requires clearance holes or slots | Extensive; requires cleaning, priming, and curing |

| Disassembly | Easy; parts can be unfastened and reused | Difficult; bonding is often permanent or requires special solvents |

| Corrosion Resistance | Prone to galvanic corrosion if dissimilar metals are used | Generally good; adhesives can act as corrosion barriers |

| Application Time | Quick installation; immediate mechanical hold | Longer curing time; dependent on adhesive chemistry |

| Cost | Higher due to hardware and labor | Lower hardware cost; adhesive cost varies |

| Common Uses in Aerospace | Airframe assembly, engine components, landing gear | Composite bonding, interior panels, aerodynamic surfaces |

Introduction to Mechanical and Chemical Fastening

Mechanical fastening involves physically joining materials using components like screws, bolts, rivets, or clips, ensuring a strong, removable connection without altering the base materials chemically. Chemical fastening relies on adhesives, sealants, or bonding agents that create a durable bond by curing and forming molecular adhesion between surfaces. Understanding these fundamental differences helps you select the appropriate fastening method based on strength, permanence, and material compatibility for your project.

Defining Mechanical Fastening

Mechanical fastening involves joining materials through physical methods such as screws, bolts, rivets, and nails, creating a secure connection without altering the chemical composition of the components. This method allows for easy disassembly and reassembly, making it ideal for applications requiring maintenance or adjustments. Common in construction, automotive, and manufacturing industries, mechanical fastening ensures strong, reliable joints with precise alignment and load distribution.

Understanding Chemical Fastening

Chemical fastening uses adhesives, such as epoxy, polyurethane, or acrylic resins, to join materials by forming strong molecular bonds. This method provides advantages in distributing stress evenly and sealing joints against moisture and corrosion. Compared to mechanical fastening like screws or bolts, chemical fastening offers enhanced aesthetics, reduced weight, and improved resistance to vibrations and fatigue.

Key Differences Between Mechanical and Chemical Fastening

Mechanical fastening relies on physical components such as screws, bolts, and rivets to join materials, offering immediate and reversible connections with high shear strength. Chemical fastening uses adhesives or resins that cure to form bonds, providing uniform stress distribution and improved resistance to vibration but typically requiring curing time. Key differences include load-bearing capacity, permanence of the bond, application complexity, and suitability for different materials and environmental conditions.

Advantages of Mechanical Fastening

Mechanical fastening offers superior strength and reliability for joining materials, making it ideal for applications requiring easy disassembly and reassembly. It provides consistent mechanical retention without chemical reactions, reducing concerns about corrosion or toxicity present in chemical adhesives. Fasteners such as bolts, screws, and rivets enable precise alignment and load distribution, enhancing structural integrity in automotive, aerospace, and construction industries.

Benefits of Chemical Fastening

Chemical fastening provides superior load distribution and vibration resistance compared to mechanical fastening, reducing the risk of joint failure in critical applications. It offers enhanced corrosion protection and seals joints against moisture and contaminants, extending the longevity of your assemblies. This method allows fastening in hard-to-reach areas and irregular surfaces where mechanical fasteners may be impractical or damaged.

Limitations of Mechanical Fasteners

Mechanical fasteners such as screws, bolts, and rivets have limitations including susceptibility to loosening under vibration, potential for corrosion, and stress concentration that can weaken materials over time. These fasteners often require precise alignment and pre-drilled holes, which can weaken the components and increase assembly time. Your application may face reduced durability and increased maintenance costs when relying solely on mechanical fastening methods.

Challenges with Chemical Fasteners

Chemical fasteners often face challenges such as sensitivity to environmental conditions including moisture, temperature fluctuations, and chemical exposure, which can degrade adhesive performance over time. The curing process may require precise conditions and extended timeframes, complicating installation and reducing productivity in manufacturing or construction settings. Limited reversibility and difficulty in quality control also present obstacles, as chemical bonds are typically permanent and non-destructive testing methods for bond integrity can be complex.

Common Applications and Industries

Mechanical fastening is widely used in automotive assembly, aerospace manufacturing, and construction due to its strength, reliability, and ease of disassembly. Chemical fastening, including adhesives and bonding agents, finds common applications in electronics, medical devices, and automotive industries where weight reduction and vibration resistance are critical. Both methods serve crucial roles in packaging, furniture production, and heavy machinery, with mechanical fastening favored for load-bearing joints and chemical fastening preferred for sealing and corrosion resistance.

Choosing the Right Fastening Method

Choosing the right fastening method depends on factors like load requirements, environmental conditions, and material compatibility. Mechanical fastening offers reusable, strong joints ideal for disassembly and maintenance, while chemical fastening provides uniform stress distribution and superior resistance to vibration and corrosion. Evaluate your project's specific needs to determine whether bolts, screws, or adhesives will deliver optimal performance and durability.

Mechanical Fastening vs Chemical Fastening Infographic

libmatt.com

libmatt.com