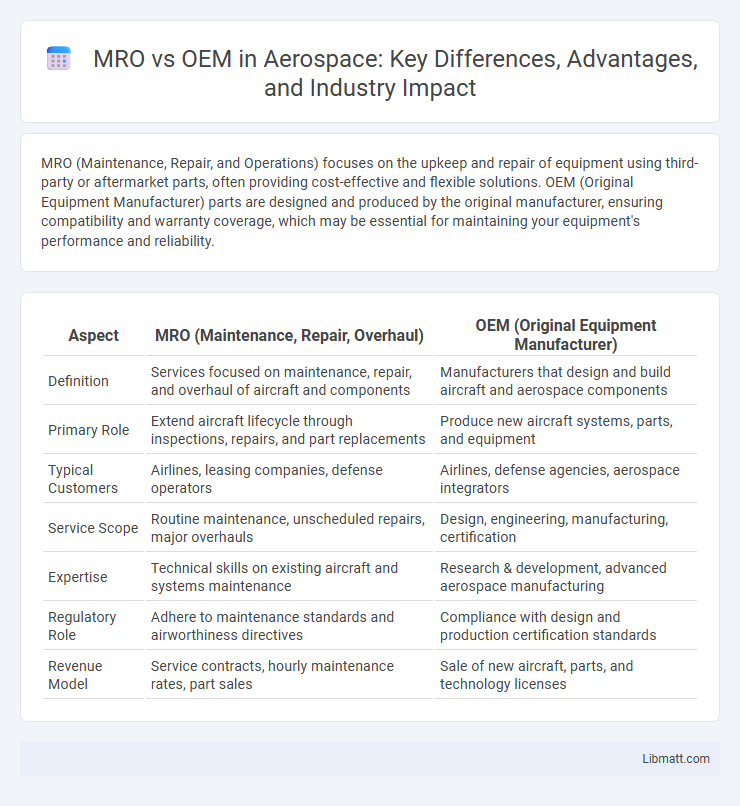

MRO (Maintenance, Repair, and Operations) focuses on the upkeep and repair of equipment using third-party or aftermarket parts, often providing cost-effective and flexible solutions. OEM (Original Equipment Manufacturer) parts are designed and produced by the original manufacturer, ensuring compatibility and warranty coverage, which may be essential for maintaining your equipment's performance and reliability.

Table of Comparison

| Aspect | MRO (Maintenance, Repair, Overhaul) | OEM (Original Equipment Manufacturer) |

|---|---|---|

| Definition | Services focused on maintenance, repair, and overhaul of aircraft and components | Manufacturers that design and build aircraft and aerospace components |

| Primary Role | Extend aircraft lifecycle through inspections, repairs, and part replacements | Produce new aircraft systems, parts, and equipment |

| Typical Customers | Airlines, leasing companies, defense operators | Airlines, defense agencies, aerospace integrators |

| Service Scope | Routine maintenance, unscheduled repairs, major overhauls | Design, engineering, manufacturing, certification |

| Expertise | Technical skills on existing aircraft and systems maintenance | Research & development, advanced aerospace manufacturing |

| Regulatory Role | Adhere to maintenance standards and airworthiness directives | Compliance with design and production certification standards |

| Revenue Model | Service contracts, hourly maintenance rates, part sales | Sale of new aircraft, parts, and technology licenses |

Understanding MRO and OEM: Key Definitions

MRO (Maintenance, Repair, and Overhaul) involves the processes and services necessary to sustain and restore equipment performance, whereas OEM (Original Equipment Manufacturer) refers to the company that designs and produces the original parts or systems. Understanding the distinction between MRO and OEM is crucial for effective asset management, cost optimization, and ensuring equipment reliability. Your choice between MRO services and OEM parts impacts maintenance strategies and operational efficiency.

Core Differences Between MRO and OEM

MRO (Maintenance, Repair, and Overhaul) providers focus on extending the life and performance of existing equipment through inspections, repairs, and upgrades, while OEMs (Original Equipment Manufacturers) design, produce, and supply new parts or systems directly from the original source. MRO services prioritize cost-effective maintenance and operational reliability, whereas OEMs emphasize innovation, compliance with original specifications, and warranty support. Your choice between MRO and OEM depends on whether you require specialized maintenance solutions or authentic, manufacturer-approved components for optimal performance.

The Role of MRO in Asset Management

MRO (Maintenance, Repair, and Overhaul) plays a critical role in asset management by ensuring operational efficiency and extending asset lifespan through timely maintenance and repairs. Effective MRO strategies reduce downtime and prevent costly failures, which supports overall asset reliability and performance optimization. Integrating MRO with OEM (Original Equipment Manufacturer) services enhances asset management by combining specialized expertise with tailored maintenance solutions.

OEM Solutions: Advantages and Limitations

OEM solutions offer the advantage of original equipment manufacturer expertise, ensuring high-quality parts and compatibility that maintain optimal performance and warranty compliance. However, the limitations include higher costs and longer lead times compared to aftermarket alternatives, which can impact budget and project timelines. Your choice depends on balancing the need for precision and reliability against cost efficiency and availability.

Cost Comparison: MRO vs OEM

Maintenance, Repair, and Overhaul (MRO) services typically offer a cost-efficient alternative compared to Original Equipment Manufacturer (OEM) parts due to lower pricing on repairs and replacement components. While OEM parts ensure guaranteed compatibility and quality, MRO providers often reduce expenses by using aftermarket or refurbished parts, significantly lowering overall maintenance costs. Companies must balance initial savings from MRO services against potential long-term costs from warranty limitations and part longevity relative to OEM originals.

Quality and Reliability: Evaluating MRO and OEM

OEM parts typically ensure superior quality and reliability due to strict manufacturing standards and original design specifications. MRO components may vary in quality, often depending on the supplier and production processes used, which can impact performance and durability. Your choice between MRO and OEM should consider the criticality of the application and the level of guaranteed reliability needed.

Turnaround Times: Speed and Efficiency

MRO (Maintenance, Repair, and Overhaul) providers often deliver faster turnaround times compared to OEMs (Original Equipment Manufacturers) by leveraging specialized repair techniques and local service networks to minimize downtime. OEMs may require longer lead times due to stringent quality control, proprietary parts, and complex certification processes, which can impact your operational schedule. Choosing the right balance between MRO speed and OEM precision ensures optimal efficiency and timely asset availability.

Regulatory Compliance: MRO vs OEM

MRO providers specialize in maintaining regulatory compliance by adhering to standards such as FAA, EASA, and other international aviation authorities, ensuring aircraft remain airworthy through certified inspections and repairs. OEMs design and manufacture aircraft parts with built-in compliance, providing detailed documentation and guidelines to meet regulatory requirements from the outset. Your choice between MRO and OEM impacts how regulatory updates and certification processes are managed throughout the aircraft lifecycle.

Choosing the Right Partner: MRO or OEM

Choosing between an MRO (Maintenance, Repair, and Overhaul) provider and an OEM (Original Equipment Manufacturer) hinges on your specific operational needs, budget constraints, and desired service scope. MRO partners often offer cost-effective, flexible solutions for diverse equipment maintenance, while OEMs ensure unmatched product knowledge and genuine parts tailored to your machinery. Your decision impacts long-term reliability, maintenance efficiency, and overall lifecycle costs, making it essential to evaluate service quality, turnaround times, and warranty coverage when selecting the right partner.

Future Trends in MRO and OEM Industries

Future trends in the MRO and OEM industries highlight increased adoption of digital twins, AI-driven predictive maintenance, and sustainable manufacturing practices. OEMs focus on integrating smart technologies into product design, while MRO providers emphasize data analytics to optimize asset performance and reduce downtime. You can expect a tighter collaboration between these sectors to enhance supply chain resilience and accelerate innovation cycles.

MRO vs OEM Infographic

libmatt.com

libmatt.com