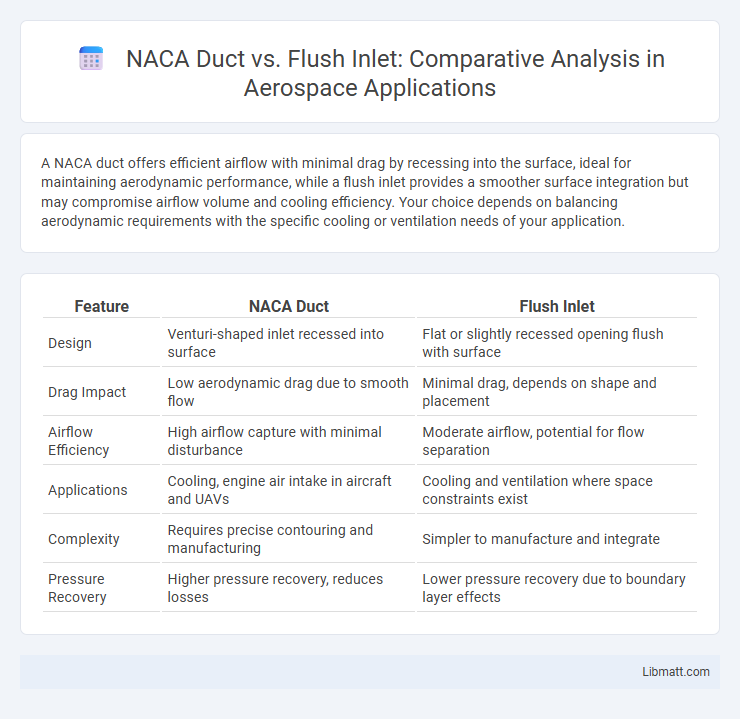

A NACA duct offers efficient airflow with minimal drag by recessing into the surface, ideal for maintaining aerodynamic performance, while a flush inlet provides a smoother surface integration but may compromise airflow volume and cooling efficiency. Your choice depends on balancing aerodynamic requirements with the specific cooling or ventilation needs of your application.

Table of Comparison

| Feature | NACA Duct | Flush Inlet |

|---|---|---|

| Design | Venturi-shaped inlet recessed into surface | Flat or slightly recessed opening flush with surface |

| Drag Impact | Low aerodynamic drag due to smooth flow | Minimal drag, depends on shape and placement |

| Airflow Efficiency | High airflow capture with minimal disturbance | Moderate airflow, potential for flow separation |

| Applications | Cooling, engine air intake in aircraft and UAVs | Cooling and ventilation where space constraints exist |

| Complexity | Requires precise contouring and manufacturing | Simpler to manufacture and integrate |

| Pressure Recovery | Higher pressure recovery, reduces losses | Lower pressure recovery due to boundary layer effects |

Introduction to NACA Ducts and Flush Inlets

NACA ducts, designed by the National Advisory Committee for Aeronautics, are engineered to provide efficient airflow with minimal drag by integrating smoothly into a surface, ideal for automotive and aerospace applications. Flush inlets, typically flat-mounted with the surface, prioritize aerodynamic cleanliness while allowing air intake, often used in high-speed vehicles and aircraft to reduce turbulence. Both designs optimize airflow management but differ in shape and flow characteristics, influencing cooling and performance outcomes.

Historical Development and Applications

NACA ducts were developed in the 1940s by the National Advisory Committee for Aeronautics to provide efficient air intake with minimal drag, primarily used in high-speed aircraft and automotive cooling systems. Flush inlets, emerging later, are integrated seamlessly into surfaces to reduce aerodynamic disturbances and are commonly applied in modern aerospace and automotive designs where stealth and aesthetics are crucial. Your choice between these inlets depends on specific aerodynamic requirements and historical performance benchmarks in various engineering applications.

Basic Design Principles

NACA ducts are designed as shallow, submerged air inlets that minimize drag by preventing flow separation and allowing smooth airflow into the duct, promoting efficient intake of air at high speeds. Flush inlets, integrated directly into the surface, prioritize maintaining aerodynamic smoothness and reducing protrusions but often require precise shaping to avoid flow disturbances and pressure losses. Your choice depends on the balance between aerodynamic efficiency and the specific airflow requirements of the application.

Aerodynamic Performance Comparison

NACA ducts exhibit lower drag compared to flush inlets due to their streamlined design, effectively channeling airflow into internal components while minimizing flow separation. Flush inlets offer a less aerodynamic profile but can suffer from increased drag and turbulent airflow, reducing overall vehicle efficiency. Performance tests demonstrate that NACA ducts improve pressure recovery and maintain smoother airflow, enhancing aerodynamic efficiency in high-speed applications.

Pressure Recovery Efficiency

NACA ducts demonstrate superior pressure recovery efficiency compared to flush inlets by minimizing flow separation and maintaining high-speed airflow attachment within the duct. The streamlined geometry of NACA ducts reduces drag and pressure losses, resulting in enhanced aerodynamic performance and improved engine intake efficiency. Flush inlets often experience increased turbulence and lower pressure recovery due to their less optimized shape, leading to decreased overall airflow effectiveness.

Impact on Drag and Lift

NACA ducts minimize drag by featuring a submerged design that maintains smooth airflow over the surface, reducing turbulence and pressure drag compared to flush inlets, which disrupt surface flow and increase drag. The low-profile nature of NACA ducts preserves lift by preventing flow separation on aerodynamic surfaces, whereas flush inlets can induce localized flow disturbances that slightly diminish lift efficiency. Optimizing your vehicle or aircraft design with NACA ducts enhances aerodynamic performance by balancing effective air intake with minimal drag and lift penalties.

Installation and Maintenance Considerations

NACA ducts offer streamlined installation by requiring minimal surface modifications, reducing the risk of structural interference and maintaining aerodynamic efficiency. Flush inlets demand precise mounting to ensure a smooth surface and may require frequent inspections to prevent debris buildup and maintain airflow performance. You should consider the ease of regular cleaning and potential access restrictions when choosing between these two inlet designs for your application.

Typical Use Cases in Aviation and Automotive

NACA ducts are commonly used in aviation for efficient air intake on aircraft surfaces, optimizing airflow with minimal drag, especially on high-speed jets and propeller aircraft. In automotive applications, flush inlets are preferred for race cars and high-performance vehicles to manage cooling and brake air efficiently while maintaining aerodynamic sleekness. Both designs balance airflow and drag reduction but serve distinct purposes aligned with the speed profiles and cooling demands of aircraft and vehicles.

Pros and Cons of NACA Ducts vs Flush Inlets

NACA ducts offer improved aerodynamic efficiency by minimizing drag and maintaining smooth airflow into the engine or cooling system, making them ideal for high-performance vehicles. Flush inlets provide a cleaner, more seamless surface integration with the vehicle body, resulting in reduced turbulence but may suffer from lower airflow capacity compared to NACA ducts. While NACA ducts enhance cooling and engine performance through optimized air intake, flush inlets prioritize aesthetics and low-profile design at the potential cost of less effective airflow management.

Choosing the Right Inlet for Your Application

Choosing the right inlet for your application depends on factors like airflow efficiency, drag reduction, and installation constraints. NACA ducts offer low drag and efficient air intake for high-speed environments, ideal for automotive or aerospace use. Flush inlets provide a smoother surface and easier integration into curved surfaces, making them suitable for applications where minimal protrusion is critical to maintain aerodynamics and aesthetics.

NACA duct vs flush inlet Infographic

libmatt.com

libmatt.com