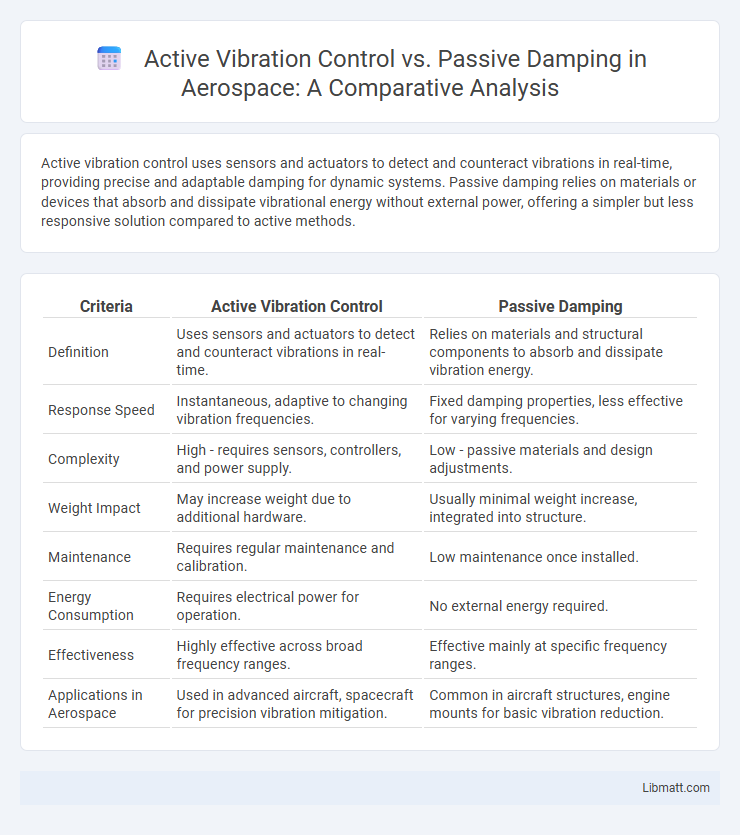

Active vibration control uses sensors and actuators to detect and counteract vibrations in real-time, providing precise and adaptable damping for dynamic systems. Passive damping relies on materials or devices that absorb and dissipate vibrational energy without external power, offering a simpler but less responsive solution compared to active methods.

Table of Comparison

| Criteria | Active Vibration Control | Passive Damping |

|---|---|---|

| Definition | Uses sensors and actuators to detect and counteract vibrations in real-time. | Relies on materials and structural components to absorb and dissipate vibration energy. |

| Response Speed | Instantaneous, adaptive to changing vibration frequencies. | Fixed damping properties, less effective for varying frequencies. |

| Complexity | High - requires sensors, controllers, and power supply. | Low - passive materials and design adjustments. |

| Weight Impact | May increase weight due to additional hardware. | Usually minimal weight increase, integrated into structure. |

| Maintenance | Requires regular maintenance and calibration. | Low maintenance once installed. |

| Energy Consumption | Requires electrical power for operation. | No external energy required. |

| Effectiveness | Highly effective across broad frequency ranges. | Effective mainly at specific frequency ranges. |

| Applications in Aerospace | Used in advanced aircraft, spacecraft for precision vibration mitigation. | Common in aircraft structures, engine mounts for basic vibration reduction. |

Introduction to Vibration Management

Active vibration control employs sensors and actuators to detect and counteract unwanted vibrations in real-time, enhancing precision and comfort in various applications. Passive damping relies on materials and structural designs that inherently absorb and dissipate vibrational energy without external power. Understanding these fundamental approaches enables you to select the most effective vibration management strategy for machinery, vehicles, or buildings based on performance requirements and operating conditions.

Fundamentals of Active Vibration Control

Active vibration control utilizes sensors and actuators to detect and counteract vibrations in real-time by applying precise control forces, enhancing system stability and performance. Unlike passive damping, which relies on fixed materials or components to dissipate energy, active control adapts dynamically to changing vibration frequencies and amplitudes. Key elements include feedback control systems, piezoelectric actuators, and accelerometers that collectively reduce resonance and improve vibration suppression efficiency.

Principles of Passive Damping Techniques

Passive damping techniques rely on inherent material properties and structural elements to dissipate vibrational energy without external power input. Common methods include viscoelastic damping materials, tuned mass dampers, and frictional interfaces, which convert mechanical vibrations into heat or redistribute energy to reduce amplitude. These techniques offer simplicity, reliability, and maintenance-free operation but may lack adaptability to varying vibration frequencies compared to active vibration control systems.

Key Differences: Active vs Passive Approaches

Active vibration control utilizes sensors, actuators, and feedback systems to detect and counteract vibrations in real-time, providing adaptive and precise mitigation. Passive damping relies on materials or mechanical components like dampers and isolators to absorb and dissipate vibrational energy without external power or control inputs. The key difference lies in active control's ability to adjust dynamically to varying conditions versus passive damping's fixed, inherent vibrational resistance.

Advantages of Active Vibration Control

Active vibration control offers superior adaptability by using sensors and actuators to continuously adjust and counteract unwanted vibrations in real-time. This method significantly enhances precision and efficiency compared to passive damping, which relies on fixed materials or structures to absorb vibrations without adjustment. Your system benefits from reduced noise, improved performance, and extended equipment lifespan through active control's dynamic response to varying vibration frequencies and amplitudes.

Benefits of Passive Damping Systems

Passive damping systems offer reliable vibration reduction without the need for external power or complex controls, ensuring low maintenance and operational costs. These systems effectively dissipate energy through materials and mechanical elements, providing consistent performance across a wide range of frequencies. Your equipment benefits from enhanced durability and noise reduction, promoting safer and quieter operating environments.

Limitations and Challenges of Both Methods

Active vibration control systems often face limitations such as the need for external power sources, complexity in real-time signal processing, and high implementation costs, which can constrain their use in resource-limited environments. Passive damping methods, while simpler and maintenance-free, struggle with limited effectiveness at low frequencies and cannot adapt to changing vibration patterns or varying operational conditions. Both approaches present challenges: active control requires sophisticated sensors and actuators for precise feedback, whereas passive damping materials may degrade over time and offer less tunability for dynamic applications.

Typical Applications in Industry

Active vibration control is commonly employed in aerospace manufacturing and precision machining to enhance equipment stability and product accuracy, while passive damping is widely used in automotive suspension systems and building structures to reduce unwanted vibrations and improve safety. Industries like electronics and semiconductor fabrication favor active control for its adaptability and precision, whereas passive solutions dominate heavy machinery and civil engineering due to their reliability and low maintenance. Combining both methods often optimizes vibration management in complex industrial environments requiring both high performance and durability.

Recent Innovations and Emerging Trends

Recent innovations in active vibration control include adaptive algorithms and smart materials that dynamically respond to changing vibration patterns, significantly improving precision and energy efficiency. Passive damping advancements leverage novel composite materials and metamaterials designed to absorb a broader frequency range with minimal maintenance. Your choice between these methods can benefit from understanding emerging trends like hybrid systems that integrate active feedback with passive components for optimized performance in complex environments.

Choosing the Right Solution for Your Needs

Active vibration control uses sensors and actuators to counteract vibrations in real time, providing precise and adaptive damping ideal for complex or variable environments. Passive damping relies on materials and mechanical devices to absorb and dissipate energy, offering a cost-effective and maintenance-free solution for consistent, low-frequency vibrations. Your choice depends on factors like vibration complexity, budget, and maintenance requirements, ensuring optimal performance tailored to your specific application.

active vibration control vs passive damping Infographic

libmatt.com

libmatt.com