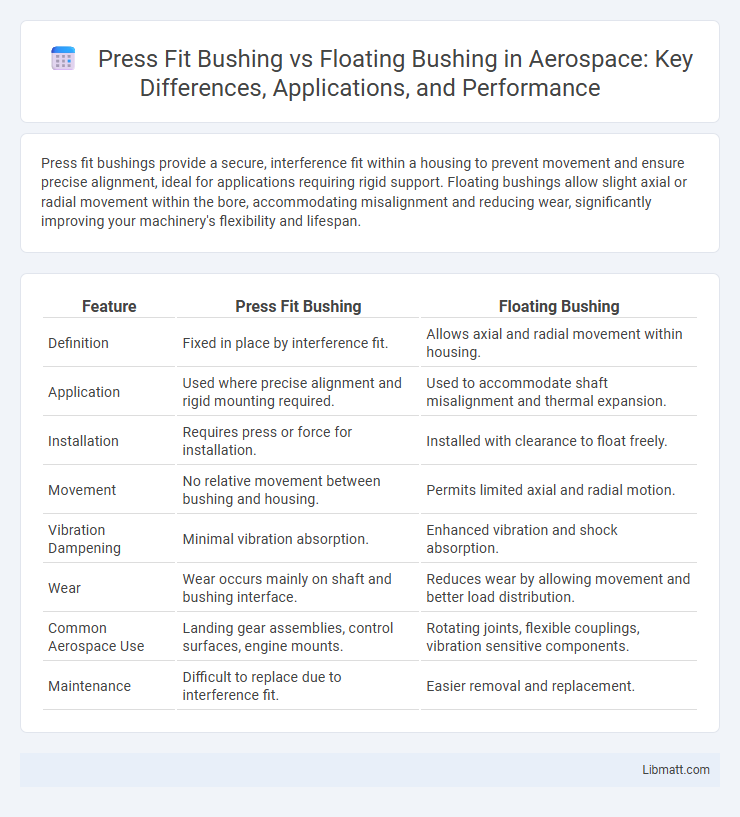

Press fit bushings provide a secure, interference fit within a housing to prevent movement and ensure precise alignment, ideal for applications requiring rigid support. Floating bushings allow slight axial or radial movement within the bore, accommodating misalignment and reducing wear, significantly improving your machinery's flexibility and lifespan.

Table of Comparison

| Feature | Press Fit Bushing | Floating Bushing |

|---|---|---|

| Definition | Fixed in place by interference fit. | Allows axial and radial movement within housing. |

| Application | Used where precise alignment and rigid mounting required. | Used to accommodate shaft misalignment and thermal expansion. |

| Installation | Requires press or force for installation. | Installed with clearance to float freely. |

| Movement | No relative movement between bushing and housing. | Permits limited axial and radial motion. |

| Vibration Dampening | Minimal vibration absorption. | Enhanced vibration and shock absorption. |

| Wear | Wear occurs mainly on shaft and bushing interface. | Reduces wear by allowing movement and better load distribution. |

| Common Aerospace Use | Landing gear assemblies, control surfaces, engine mounts. | Rotating joints, flexible couplings, vibration sensitive components. |

| Maintenance | Difficult to replace due to interference fit. | Easier removal and replacement. |

Introduction to Press Fit and Floating Bushings

Press fit bushings are designed to be securely installed by interference fit, creating a tight and stable connection within a housing, providing high load capacity and precise alignment. Floating bushings allow controlled movement or self-alignment within their housings, reducing stress and accommodating shaft deflections or misalignments. Understanding the differences helps you select the right bushing type for applications requiring either rigid support or flexible accommodation.

Definition of Press Fit Bushing

Press fit bushing is a type of bearing sleeve designed to be inserted into a housing or bore with an interference fit, creating a secure, non-movable connection through mechanical friction. Unlike floating bushings that allow slight movement or self-alignment within their housing, press fit bushings rely on precision machining and press insertion to maintain rigid positioning. Your choice between press fit and floating bushings impacts assembly stability, vibration resistance, and load distribution in mechanical applications.

Definition of Floating Bushing

A floating bushing is a cylindrical bearing component designed to allow slight radial and axial movement, reducing friction and accommodating misalignment between parts. Unlike a press fit bushing, which is rigidly fixed within a housing, a floating bushing is free to move within its bore, improving load distribution and extending the lifespan of machinery components. This flexibility makes floating bushings ideal for applications involving shaft misalignment and thermal expansion.

Key Differences Between Press Fit and Floating Bushing

Press fit bushings are rigidly installed into a housing with an interference fit, providing a fixed, immovable bearing surface ideal for high-load applications requiring precise alignment. Floating bushings, by contrast, are designed to move slightly within their housing, accommodating misalignment and reducing wear by allowing self-adjustment during operation. Your choice between these bushings depends on factors like load conditions, shaft movement, and the need for alignment flexibility.

Advantages of Press Fit Bushings

Press fit bushings provide superior stability and alignment due to their tight interference fit within the housing, reducing movement and wear in high-load applications. Their secure installation enhances load distribution and minimizes vibrations, leading to longer service life and improved mechanical performance. You benefit from reliable, maintenance-free operation in precise machinery where consistent positioning is crucial.

Advantages of Floating Bushings

Floating bushings offer superior self-alignment capabilities, reducing shaft misalignment and minimizing wear, which enhances machinery lifespan and performance. Their design allows for better heat dissipation compared to press fit bushings, preventing overheating in high-speed or heavy-load applications. You benefit from easier maintenance and replacement due to less rigid installation requirements, making floating bushings ideal for dynamic and variable operational conditions.

Common Applications of Press Fit Bushings

Press fit bushings are commonly used in automotive engines, industrial machinery, and agricultural equipment due to their high load-bearing capacity and precise alignment capabilities. These bushings provide a secure, interference-fit installation that minimizes movement and wear, making them ideal for applications subjected to heavy loads and vibrations. You can rely on press fit bushings in scenarios where durability and consistent performance under stress are critical.

Common Applications of Floating Bushings

Floating bushings are commonly used in applications requiring reduced friction and accommodating misalignment, such as in automotive suspension systems, industrial machinery, and agricultural equipment. These bushings provide axial movement and self-aligning capabilities, making them ideal for pivot points and rotating shafts subjected to lateral loads. Your machinery benefits from improved durability and smoother operation when incorporating floating bushings in dynamic environments.

Factors to Consider When Choosing Between Press Fit and Floating Bushings

Consider load capacity and shaft alignment when choosing between press fit and floating bushings; press fit bushings provide a secure, fixed position for high-load applications, while floating bushings accommodate shaft misalignment and thermal expansion. Material compatibility and ease of maintenance also impact selection, with floating bushings offering easier replacement and better tolerance to wear. Environmental conditions such as temperature, lubrication availability, and vibration influence durability and performance, guiding the decision between press fit and floating designs.

Summary: Which Bushing Type Is Right for Your Project?

Press fit bushings provide a rigid, immovable connection ideal for applications requiring precise alignment and minimal movement under high loads, offering enhanced stability and durability. Floating bushings accommodate shaft misalignment and thermal expansion, reducing stress and wear in dynamic or high-vibration environments, suitable for projects with variable load conditions. Choosing the right bushing depends on load demands, alignment precision, and environmental factors, with press fit bushings favored for fixed, high-precision setups and floating bushings preferred for flexible, maintenance-friendly applications.

press fit bushing vs floating bushing Infographic

libmatt.com

libmatt.com