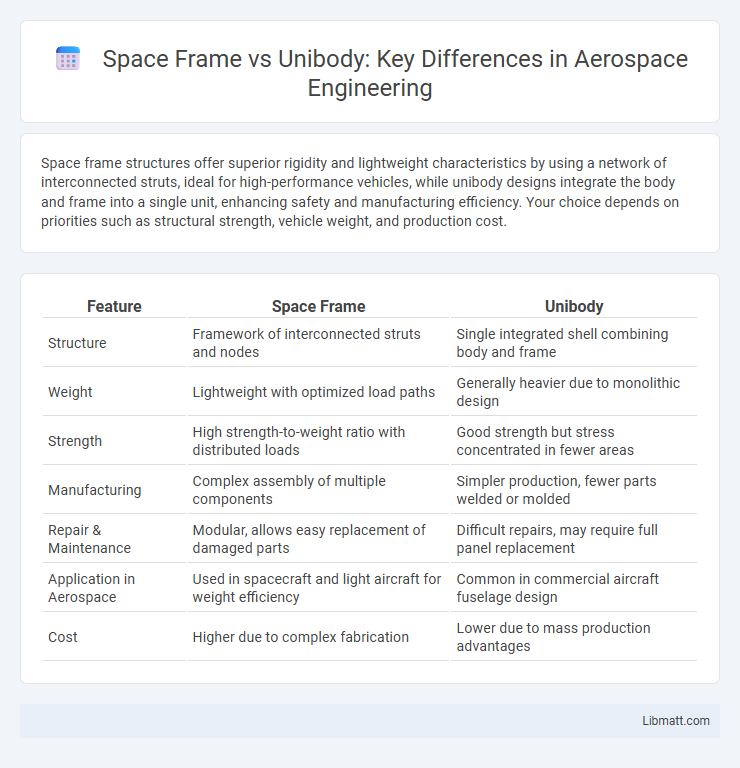

Space frame structures offer superior rigidity and lightweight characteristics by using a network of interconnected struts, ideal for high-performance vehicles, while unibody designs integrate the body and frame into a single unit, enhancing safety and manufacturing efficiency. Your choice depends on priorities such as structural strength, vehicle weight, and production cost.

Table of Comparison

| Feature | Space Frame | Unibody |

|---|---|---|

| Structure | Framework of interconnected struts and nodes | Single integrated shell combining body and frame |

| Weight | Lightweight with optimized load paths | Generally heavier due to monolithic design |

| Strength | High strength-to-weight ratio with distributed loads | Good strength but stress concentrated in fewer areas |

| Manufacturing | Complex assembly of multiple components | Simpler production, fewer parts welded or molded |

| Repair & Maintenance | Modular, allows easy replacement of damaged parts | Difficult repairs, may require full panel replacement |

| Application in Aerospace | Used in spacecraft and light aircraft for weight efficiency | Common in commercial aircraft fuselage design |

| Cost | Higher due to complex fabrication | Lower due to mass production advantages |

Introduction to Space Frame and Unibody Designs

Space frame and unibody designs represent two fundamental automotive chassis architectures critical to vehicle performance and safety. Space frame construction uses a rigid tubular steel or aluminum framework supporting body panels, optimizing structural integrity and weight distribution. Your choice between space frame and unibody impacts vehicle rigidity, crashworthiness, and manufacturing complexity, crucial factors in modern automotive engineering.

Structural Differences: Space Frame vs Unibody

Space frame structures consist of a three-dimensional framework of interconnected beams that distribute loads evenly, providing high rigidity and lightweight characteristics. Unibody designs integrate the vehicle's body and frame into a single cohesive shell, enhancing overall structural integrity and crash safety by dispersing impact forces across the entire body. The key structural difference lies in the space frame's modular beam network versus the unibody's continuous, welded sheet metal construction.

Materials Used in Space Frame and Unibody Construction

Space frame construction primarily utilizes lightweight yet strong materials such as aluminum and high-strength steel, enhancing rigidity while reducing overall vehicle weight. Unibody construction often incorporates stamped steel sheets combined with strategic use of high-strength steel and sometimes aluminum alloys to balance strength, safety, and manufacturing efficiency. The material choices in space frames enable greater design flexibility and improved crash energy management compared to the more integrated, load-bearing structure of unibody designs.

Weight and Performance Comparison

Space frame designs typically offer higher structural rigidity while maintaining lower weight due to the use of interconnected tubular elements made from materials like aluminum or steel alloys. Unibody constructions integrate the body and frame into a single piece, resulting in increased overall weight but enhanced crash safety and improved aerodynamic performance. Vehicles with space frames often deliver superior handling and acceleration owing to reduced mass, whereas unibody platforms prioritize stability and comfort with a slightly heavier structure.

Manufacturing Process and Cost Implications

Space frame construction involves assembling a network of interconnected metal tubes or beams, typically made from steel or aluminum, requiring extensive welding and precise fabrication, resulting in higher labor and tooling costs. Unibody manufacturing integrates the body and frame into a single stamped steel or aluminum structure using large presses and robotic welding, streamlining production and reducing material usage. Consequently, unibody designs generally lower manufacturing complexity and costs compared to the more intricate and resource-intensive space frame approach.

Safety Considerations: Crashworthiness and Durability

Space frame construction enhances crashworthiness by distributing impact forces evenly across the welded metal framework, improving occupant protection during collisions. Unibody designs integrate the body and frame into a single structure, optimizing energy absorption through crumple zones and providing excellent durability for everyday driving conditions. Your choice between space frame and unibody affects safety performance, with space frames typically favoring strength and repairability, while unibodies focus on engineered deformation and weight efficiency.

Repair and Maintenance Differences

Space frame vehicles often feature modular components that simplify repair and maintenance by allowing damaged sections to be replaced independently, resulting in lower labor costs and shorter downtime. In contrast, unibody constructions integrate the body and frame into a single structure, making repairs more complex and costly as damage to one area can affect overall structural integrity, requiring specialized equipment and longer repair times. Unibody designs typically demand body shops with advanced technology to restore precise alignment, while space frames prioritize ease of access for routine maintenance and part replacement.

Applications in the Automotive Industry

Space frame structures dominate high-performance automotive applications such as supercars and race cars due to their superior rigidity and lightweight characteristics, enabling enhanced handling and acceleration. Unibody construction is prevalent in mass-produced passenger vehicles, offering cost-efficient manufacturing, improved crash safety, and better fuel economy through integrated body and frame design. Both technologies influence vehicle dynamics and safety standards significantly, with space frames favored in niche markets and unibody construction favored for mainstream consumer vehicles.

Advantages and Disadvantages of Each Design

Space frame construction offers superior rigidity and easier repairability due to its distinct metal framework, enhancing safety and performance in high-stress conditions. Unibody design provides better weight efficiency and improved fuel economy by integrating the body and frame into a single structure, but can be more costly to repair after damage. You should consider space frames for heavy-duty durability and unibody for lighter, more efficient everyday driving.

Future Trends in Vehicle Chassis Engineering

Future trends in vehicle chassis engineering emphasize lightweight materials and advanced manufacturing techniques to enhance the performance of both space frame and unibody structures. Space frame designs increasingly integrate carbon fiber composites and modular components for improved strength-to-weight ratios and repairability. Unibody chassis continue to evolve with multi-material construction and advanced joining methods, enabling greater rigidity and crash safety while reducing overall vehicle weight.

space frame vs unibody Infographic

libmatt.com

libmatt.com