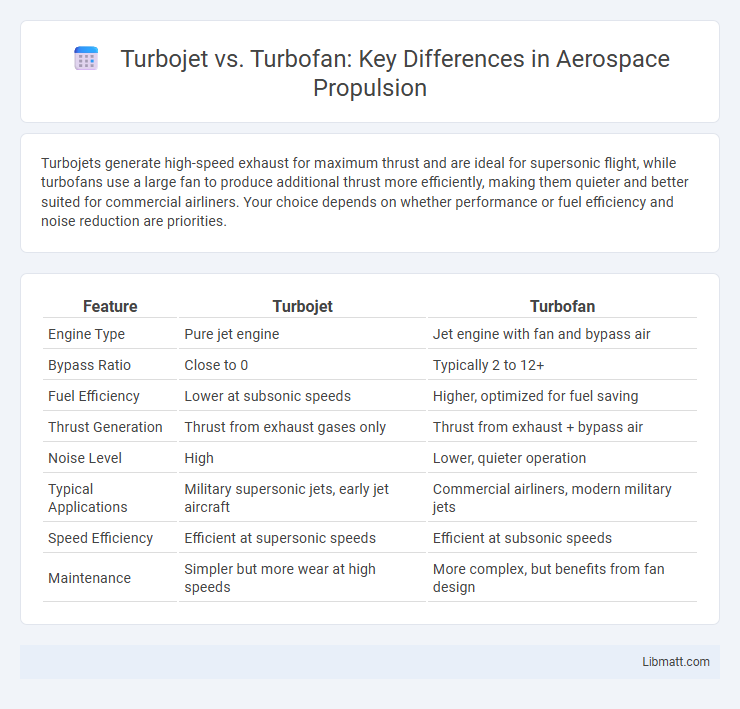

Turbojets generate high-speed exhaust for maximum thrust and are ideal for supersonic flight, while turbofans use a large fan to produce additional thrust more efficiently, making them quieter and better suited for commercial airliners. Your choice depends on whether performance or fuel efficiency and noise reduction are priorities.

Table of Comparison

| Feature | Turbojet | Turbofan |

|---|---|---|

| Engine Type | Pure jet engine | Jet engine with fan and bypass air |

| Bypass Ratio | Close to 0 | Typically 2 to 12+ |

| Fuel Efficiency | Lower at subsonic speeds | Higher, optimized for fuel saving |

| Thrust Generation | Thrust from exhaust gases only | Thrust from exhaust + bypass air |

| Noise Level | High | Lower, quieter operation |

| Typical Applications | Military supersonic jets, early jet aircraft | Commercial airliners, modern military jets |

| Speed Efficiency | Efficient at supersonic speeds | Efficient at subsonic speeds |

| Maintenance | Simpler but more wear at high speeds | More complex, but benefits from fan design |

Introduction to Turbojet and Turbofan Engines

Turbojet engines generate thrust by expelling high-velocity jet exhaust directly from combustion, optimizing speed and altitude performance for military and supersonic aircraft. Turbofan engines incorporate a large fan at the front that produces additional thrust by bypassing air around the engine core, significantly enhancing fuel efficiency and reducing noise levels for commercial airliners. The fundamental difference lies in bypass ratio, where turbojets have negligible bypass, and turbofans feature high bypass ratios, improving overall propulsion efficiency.

Historical Development of Jet Engines

The historical development of jet engines began with turbojets in the 1930s, pioneered by engineers like Frank Whittle and Hans von Ohain, revolutionizing aviation with their high-speed thrust capabilities. Turbofan engines emerged later in the 1960s, combining the turbojet core with a large bypass fan to enhance fuel efficiency and reduce noise, becoming the dominant engine type in commercial aviation. Your understanding of these advancements highlights the shift from pure speed-focused designs to more balanced, efficient propulsion systems.

Core Principles: How Turbojets Work

Turbojets operate by drawing air into the engine, compressing it through multiple stages, mixing it with fuel, and igniting the mixture to generate high-velocity exhaust gases that produce thrust. This core principle relies on the rapid acceleration of exhaust gases without bypassing air, making turbojets efficient at high speeds and altitudes. Your understanding of this process highlights the fundamental difference from turbofans, which incorporate a bypass airflow to improve fuel efficiency and reduce noise.

Core Principles: How Turbofans Work

Turbofans operate by drawing air through a large front fan, which bypasses a portion of the airflow around the engine core, enhancing fuel efficiency and reducing noise compared to turbojets. The core compresses air, mixes it with fuel, and ignites it to produce high-velocity exhaust, while the bypassed airflow provides additional thrust with lower fuel consumption. This dual-flow system distinguishes turbofans from pure turbojets, optimizing performance for commercial and military aircraft with improved thrust-to-fuel ratios.

Efficiency Comparison: Turbojet vs Turbofan

Turbofans exhibit higher fuel efficiency than turbojets, particularly at subsonic speeds, due to their larger bypass ratio that allows more air to bypass the engine core, reducing specific fuel consumption. Turbojets generate greater thrust at high speeds and altitudes but consume more fuel as they rely solely on core airflow, making them less efficient for typical commercial aviation. Modern commercial aircraft predominantly use turbofan engines to optimize efficiency and reduce emissions during cruise flight.

Performance Differences in Various Flight Regimes

Turbojets excel in high-speed, high-altitude flight with superior thrust-to-weight ratios and efficient performance above Mach 2, making them ideal for supersonic applications. Turbofans provide greater fuel efficiency, quieter operation, and improved thrust at subsonic speeds, optimizing performance in commercial aviation and cruise conditions below Mach 1. The bypass airflow in turbofans enhances thrust during takeoff and climb phases, while turbojets maintain consistent power output in thin air at extreme altitudes.

Fuel Consumption and Environmental Impact

Turbojets exhibit higher fuel consumption due to their efficient operation at high speeds but lower bypass ratios, resulting in greater fuel burn per thrust unit. Turbofans offer improved fuel efficiency by incorporating larger bypass ratios that mix bypass air with jet exhaust, significantly reducing fuel consumption and emissions. This design lowers environmental impact through decreased greenhouse gas output and reduced noise pollution compared to turbojets.

Common Applications of Turbojets and Turbofans

Turbojets are commonly used in military fighter jets and high-speed aircraft due to their high thrust and efficiency at supersonic speeds. Turbofans dominate commercial aviation, powering most passenger airliners with better fuel efficiency and lower noise levels at subsonic speeds. Regional jets and business aircraft often employ turbofans to balance performance and operational cost.

Maintenance and Operational Costs

Turbojets generally incur higher operational costs due to lower fuel efficiency and more frequent maintenance needs stemming from simpler bypass designs. Turbofans, with their larger fan and bypass airflow, offer improved fuel economy and reduced wear on engine components, leading to lower maintenance expenses and extended service intervals. Consequently, turbofans are preferred for commercial aviation where cost-effectiveness and reliability are critical factors.

Future Trends in Jet Engine Technology

Future trends in jet engine technology emphasize turbofan engines due to their superior fuel efficiency and reduced noise levels compared to turbojets. Advancements in materials and aerodynamic design are enhancing turbofan performance, making them the preferred choice for commercial aviation and environmental sustainability. Your investment in these evolving technologies will support cleaner, quieter, and more efficient air travel.

turbojet vs turbofan Infographic

libmatt.com

libmatt.com